The EU-Funded upPE-T project is investigating how the degradation products of PE and PET packaging waste can be raw material for the manufacture of PHBV for biodegradable packaging, following circular economy criteria.

Biotechnology is an important discipline in transitioning to more environmentally friendly industrial processes. By using renewable resources and non-toxic reactants, fewer energy inputs are required than in traditional manufacturing.

The upPE-T project has created a value chain for upcycling plastic waste based on biotechnological processes connected in a closed loop, from waste to high-value product, with zero waste and using secondary raw materials, following circular economy criteria.

Enzymatic upcycling

The principle of the upPE-T value chain is the biotechnological upcycling of plastic packaging waste following a pathway that comprises the following steps:

Polymer waste pretreatment

CETEC Technological Centre, Tampere University, and the University of Greifswald have worked on developing pretreatments for conditioning PET and PE waste to make the materials more prone to attack by enzymes. This is done by decreasing the polymer crystallinity (especially important for PET), creating reactive functional groups, increasing the polymer polarity (important for PE), and increasing its specific surface area by grinding or micronisation.

This all leads to an enhanced enzymatic polymer conversion rate and yield. The synergistic effect of the different pretreatments has been proven to be the optimal route and key factor to boost the efficiency of the enzymatic reactions.

Enzyme engineering

The company Enzymicals AG, together with the University of Greifswald, have applied computational biology methods to discover novel enzymes with improved catalytic activity and thermal stability as an important step to enhance the performance of the current existing enzymes.

In the case of PET enzymatic upcycling, mutagenesis leads to increased process stability and high space-time yields in the reactor.

PE degradation is much more difficult as the polymer has no reactive groups for enzymatic attack, and no credible reports exist in the scientific literature.

The project has developed a combination of chemical oxidation and an enzyme cascade, which still leads to low conversions but can be improved upon.

In this regard, the University of Greifswald has started by making a metagenome library from soil polluted with hydrocarbons as a mimic for PE polymer chains and developing a screening method to find peroxidases that have activity on the model substrate.

From this method, 71 positive hits were found, and they are currently subcloning these in an expression vector for further characterisation.

Optimisation of the enzymatic degradation process and scaling up

The different new enzyme variants have been cloned, produced, purified, and subsequently tested at a lab scale to evaluate their degradation activity. Synergy and cascade degradation using several enzymes has been shown to be the best strategy to reach the efficiency targets for the polymer degradation processes.

To bring the enzymatic upcycling process closer to an industrial scale, Enzymicals AG is optimising the enzymatic conversion of PET at a larger scale in higher space-time yields with fewer enzymes in a ten-litre reactor. An important part of this scaling-up step is the recovery of by-products and valorisation with a final goal of 100% water recirculation and enzyme recovery, contributing to reducing the final cost and the overall environmental impact.

The different degradation products from PE and PET enzymatic conversion: terephthalic acid, ethylene glycol and short-chain carboxylic acids, will be converted into secondary raw materials to be used in the production and green extraction of polyhydroxyalkanoate of the type of PHBV. We are currently scaling up the fermentation process for making the PHBV powder.

Production of polyhydroxybutyrate valerate from waste and secondary raw materials

CETECBIOTECHNOLOGY and The University of Alicante are developing a cell factory for the production of polyhydroxyalkanoate biobased biodegradable plastics by using Haloferax mediterranei, halophilic micro-organisms able to synthesise the copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), which is a better polymer and more similar to petroleum-derived plastics because the incorporation of 3-hydroxyvalerate leads to improved properties such as higher elasticity and lower crystallinity.

The PHBV biosynthesis pathways allow for facing different enhancement production strategies, not only based on nutrient modification but also on the genetic engineering of the microorganism.

Besides, to develop a more sustainable bioprocess, two approaches are being addressed: on the one hand, the use of organic waste as the carbon source for biomass growth, and on the other hand, the extraction of the PHBV from the biomass using green solvents.

Genetic engineering of the PHBV-producing microorganism

Haloferax mediterranei is a halophilic archaeon inhabiting extreme salty environments like salt marshes and salted ponds from which salts for human consumption are isolated. It was first isolated from Santa Pola salterns ponds in south-east Spain.

This haloarchaeon and other haloarchaeal strains show a genuine metabolism of high versatility, making possible the use of different natural sources and even wastes as sources of nutrients for growth. Besides, cells can produce molecules of biotechnological interest like enzymes (reductases and dehydrogenases), carotenoids (like bacterioruberin) and bioplastics (polyhydroxyalkanoates: PHAs).

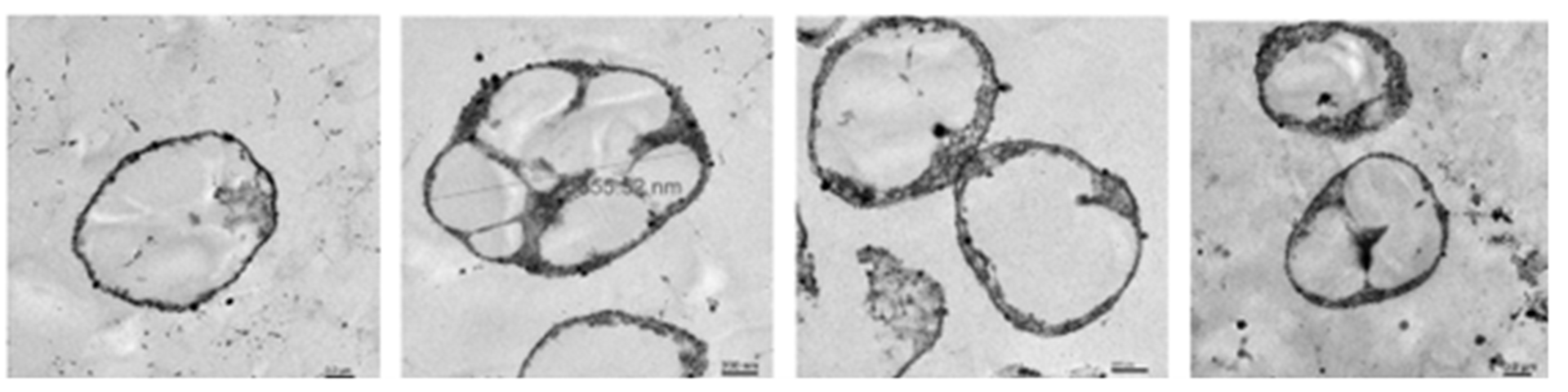

In the context of the upPE-T project, cells of H. mediterranei have been transformed by the University of Alicante by using molecular biology tools to overexpress genes coding one of the key enzymes required for synthesising PHAs: PHA synthase.

The results reveal that the transformed strain of H. mediterranei can overexpress PHA synthase, which has been purified and partially characterised from a biochemical point of view. This strain produces more polyhydroxibutyrate valerate (PHBV) with a higher fraction of 3HV than occurs in the wild. The results are promising because, among PHAs, PHBV shows the best physicochemical properties for further use in several industrial processes.

Thus, combining this strategy with nutritional modifications has favoured the synthesis of PHAs, even increasing the production of PHBV. The size of the PHA granules has also been explored by TEM analysis. The results clearly revealed that the size of the granules and the % of the cytoplasm occupied by them is higher in the overexpression strain than in the parental strain.

Production of PHBV using waste as carbon and nitrogen source

CETECBIOTECHNOLOGY and the University of Alicante have worked on developing a cell factory to produce PHBV using industrial waste. Two different types of waste have been tested as a carbon and nitrogen source for the production of PHBV by Holoferax mediterranei, the biomass obtained in the bioconversion of TPA (PET waste degradation product) and sugar-rich waste from the candy industry.

The process has been optimised by conducting the necessary tests varying the different process parameters, such as salinity, temperature, or aeration, and comparing its performance with the control (using conventional nitrogen and carbon sources). Both wastes have proved to be good sources for the effective growth of the H. mediterranei biomass and production of PHBV.

Another important ongoing research is the modulation of the hydroxyvalerate content by testing different kinds and ratios of nutrients and the scaling up of the process from lab to up to 30L, 100L, 500L, and 1,000L fermenters for the production of kilograms of PHBV and further semi-industrial validation in food packaging.

Green extraction of PHBV from the biomass

The extraction of PHAs using organic solvents, such as chloroform or dichloromethane, is one of the traditional methods employed to obtain these bioplastics from microorganisms, but it raises significant concerns in terms of environmental impact and safety.

Consequently, the large-scale production of PHAs (particularly PHBV) as an alternative to petroleum plastic derivatives requires designing and optimising environmentally friendly protocols for biomass downstream processing, making PHA isolation and purification through the greenest processes possible.

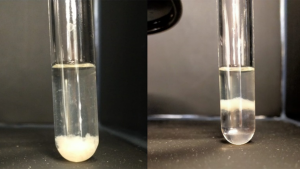

In the green process optimised by the University of Alicante, aqueous two-phase systems (ATPS) involving environmentally friendly compounds like phosphate, polyethylene glycol (PEG) and deep eutectic solvents (DES) are used. PEG and phosphate are used to create two immiscible liquid phases within a single aqueous system in these aqueous two-phase systems. PEG is a polymeric substance that dissolves in water, forming a polymer-rich phase, while phosphate dissolves in water, forming a salt-rich phase. The ability of these two phases to naturally separate in an aqueous system is due to differences in their chemical and physical properties.

In the case of DES, these eutectic mixtures are formed by combining two or more components, typically a hydrogen donor, such as a quaternary ammonium compound, and a hydrogen acceptor, such as an acid or a weak base.

Optimising PHBV based formulations for flexible and rigid biodegradable plastics

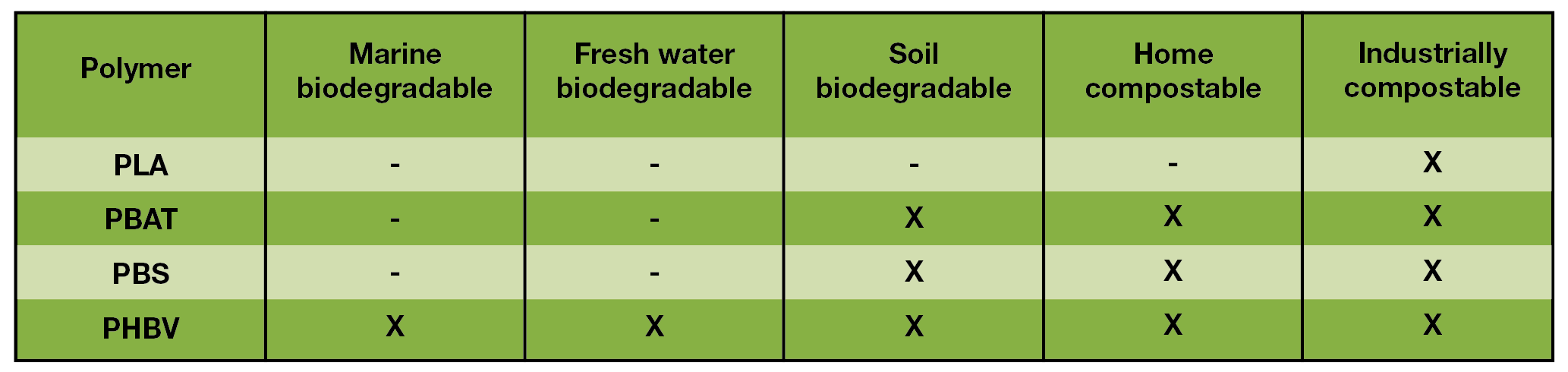

The accumulation of plastic materials in the environment is a widely recognised problem that requires imaginative solutions from the scientific community. Biodegradable plastics can help to reduce the presence of plastics in the environment, mainly in certain uses, such as in agriculture and in certain types of packaging. There are several biodegradable plastics on the market for application to different products. The above table summarises the main current options and how they can be removed from the environment:

In this context, the upPE-T partners BIOMI and CETEC are focused on the development of biodegradable formulations with the PHBV produced in the upPE-T cell factory. This material has two main advantages over other biodegradable polymers.

Firstly, it is not a synthetic polymer but is produced naturally by several microorganisms as a carbon reservoir. Secondly, the potential of PHBV lies in its wide biodegradability profile, being biodegradable in any medium, from soil to marine water.

In addition, its mechanical properties can be tuned by modifying the hydroxyvalerate content in the PHBV produced by the microorganisms, opening the possibility of obtaining a more rigid or flexible polymer.

Another important task of the project is to investigate how the addition of PHBV to other biodegradable plastics influence the mechanical properties and their biodegradation. In this regard, several blends made of PHBV as the main component and PLA or PBS are optimised to ensure processability and increase biodegradability.

Moreover, we are using nanotechnology to improve the barrier properties of biodegradable plastics by using silica nanoparticles, functionalised by the University of BOKU, to make them more compatible with biodegradable polyesters. The most promising blends will be scaled up and validated as flexible packaging films, rigid or semirigid solutions (e.g. trays, sticks) by various end users representing different food sectors and related needs.

Environmental impact assessment of upPE-t solution

The evaluation of the environmental impact of the processes developed for the upPE-T value chain is of paramount importance, with several partners dedicated to this end. DIGIOTOUCH is performing the life cycle assessment and by-product valorisation studies of upPE-T solution (products and processes).

The methodology is extended for Social-LCA and LCC and will be an important tool for decision-making when it comes to comparing different scenarios. BOKU University and CETEC are evaluating the biodegradability and recyclability of the final upPE-T products, following European standards, and contributing to improve them.

Two main environmental conditions, namely mesophilic and thermophilic temperature ranges, are used to simulate multiple biodegradation habitats, such as freshwater bodies, wastewater treatment plants, home, or garden compost and industrial thermophilic compost.

The upPE-T Project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 953214.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.