A new $20m project, led by Louisiana State University (LSU), aims to introduce new technologies and materials for a range of manufacturing industries using machine learning and 3D printing.

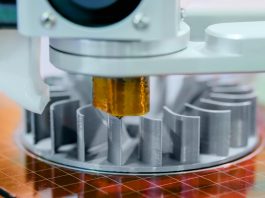

Supported by the National Science Foundation (NSF), this research will be improving upon 3D printer assisted technology. 3D printing holds the potential to reinvent the manufacturing industry, however the materials currently available do not meet the industry requirements.

Testing 3D printer materials

In order to further the adoption of 3D printing in manufacturing industries, scientists and engineers will be discovering and testing the composition, processing, microstructure, performance, and structural integrity of materials that can be used in advanced 3D printing.

Michael Khonsari, from the LSU Department of Mechanical Engineering and the project director for the newly established Louisiana Materials Design Alliance, said: “This game-changing work is at the frontiers of science, engineering, and education. We are committed to connecting our research discoveries to industry, so they can have real-world impacts.”

The Louisiana Materials Design Alliance enables the collaboration of scientists and engineers from five Louisiana universities—Louisiana Tech, University of Louisiana Lafayette, Southern University A&M, Tulane University and LSU.

“This is a great win for Louisiana and the economy that will provide a much-needed boost to the manufacturing industry in our state and across the US We are thankful for the National Science Foundation’s support of the research expertise at LSU and throughout Louisiana,” said LSU Interim President Tom Galligan.

“This project is a superb example of synergistic, inter-related research and educational activities that support a larger national scientific priority area,” said Ann Stapleton, NSF Established Program to Stimulate Collaborative Research Director.

Developing state-of-the-art machine learning

LAMDA researchers will develop and use state-of-the-art machine learning to efficiently seek the specific materials that can deliver the best performance metrics and structural integrity for 3D printing.

“Any trial and error in the lab would take days and years of design. This is why the team will use machine learning to figure out what type of materials to use, and how to optimise them. Essentially, LAMDA will develop a framework for material design guided by machine learning,” Khonsari said.

“This alliance brings some of the top talent at LSU and around the state together to do what we do best: discover, innovate, test and deliver. All along the way, LAMDA will work closely with key industry leaders and educate the workforce,” said LSU Vice President of Research & Economic Development Sam Bentley.

The five-year NSF grant will support 14 new faculty at the five universities that are part of LAMDA. “We want an influx of new faculty as well as industry partners to come and work with us,” Khonsari said.