The 5GSOLAR project in the Laboratory of Thin Films Chemical Technologies at TalTech promotes next-generation earth-abundant photovoltaics in Europe.

The Laboratory of Thin Films Chemical Technologies in the Department of Materials and Environmental Technology at Tallinn University of Technology (TalTech), Estonia, was founded by Professor Malle Krunks in 2011. The research group, established a decade earlier, has extensive expertise in developing metal oxide, binary, and ternary metal chalcogenide thin films and nanostructured materials for solar cells and electronic and environmental applications.

The 5GSOLAR project, which has received funding from the European Commission (EC), provides solutions for expanding the team of experts, growing the stakeholder’s network, and increasing research excellence and visibility.

Bridging the gap between research results and commercial development

5GSOLAR aims to accelerate the development and deployment of research in emerging inorganic materials and solar cells, thereby providing the platform for bridging the gap between research and technology transfer. 5GSOLAR’s long-term aim is to pave the way for deploying European Union (EU) solar photovoltaics (PVs) at manufacturing capacity.

The EU Solar Energy Strategy, launched by the European Commission in May 2022, names solar energy as the kingpin in the rapid deployment of renewable energy. To meet 30% of the world’s energy demand target (~10 TW) – set by the EU Strategic Energy Technology Plan – by 2040-2050,1 additional research and development on emerging PV absorbers is needed to diversify the portfolio of incumbent solar technologies.

In this context, one of the biggest challenges in achieving the EU 2050 objectives is to “reduce the solar PV generation cost, which will offset increases in energy system cost due to batteries or other storage technologies.” To meet the target of this rapidly evolving market, next-generation photovoltaic technologies as a complement to c-Si and single-junction counterparts, as well as CdTe and CiGS thin film technologies, will be required.

The emergence of new photovoltaic technologies

For a new PV technology, it is insufficient to be only competitive with the current technologies in the point of view of efficiency and reliability. New technologies should also be green, environmentally friendly, and comprise earth-abundant chemical elements.2 In addition, the low capital expenditures must be compatible with low-CapEx production processes to ensure rapid scaling.3

In this context, it is easy to see why research continues to look beyond the established technologies. The future PV market must be based on various innovative solutions and products to meet the market growth potential while addressing the grand environmental challenges faced by the EU and the world to achieve a green electricity market.

The green energy transition requires progress in the range of PV applications

5GSOLAR’s scientific focus is on developing emerging inorganic earth-abundant chalcogenide materials, such as antimony and bismuth-based chalcogenides including Sb2(S,Se)3 and (Sb, Bi)2Se3.

These materials are in the scientific spotlight due to several noticeable features. They are distinct from traditional thin-film technologies, such as tuneable bandgap (1.1-1.7 eV), high-absorption coefficient (>105 cm-1), and earth-abundant constituents.

These unique material properties have resulted in solar cell superstrate and substrate configuration, with power conversion efficiencies of around 10%, and allowing far greater flexibility in cell structure and fabrication methods than in established inorganic thin-film technologies.

These materials can play an essential role in the future development of inorganic solar cells, for example, in building integrated photovoltaic (BIPV) as semi-transparent electricity-producing windows, agro photovoltaics, tandem solar cells, product integrated photovoltaics (PIPV), PV-powered Internet of Things (IoT) devices, and more. Thus, laying the groundwork for zero-energy buildings, smart cities, and smart villages.

5GSOLAR targets the development of solar cells for lightweight, semi-transparent electricity-producing windows, which comprise non-toxic stable materials directly deposited onto window glass. This can be easily integrated into existing windows during construction, effectively utilising building space and the cost and weight saving of building materials.

Recent theoretical studies by NREL showed that a PV window with a power conversion efficiency as low as 6% reduces the energy use of a building by more than 30%.4 Taking advantage of this power-saving potential and considering high AVT over 20-30% implies that this innovative technology device can be integrated everywhere, including building windows, front panels of cars, and even human skin.

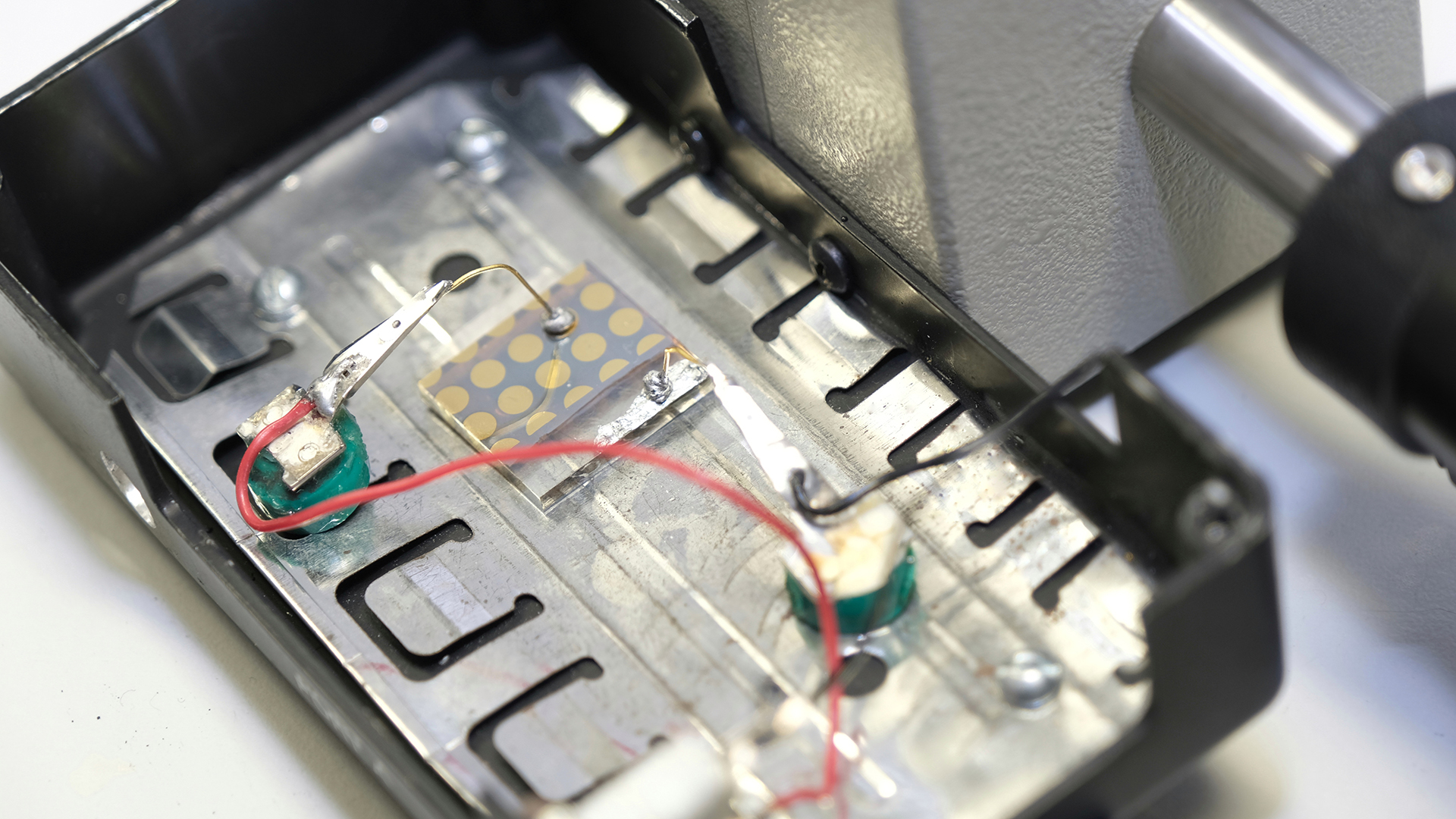

Another critical innovation area of 5GSOLAR is the development of thin film devices with an efficiency of ≥ 10 %, which will give the sensors a significant power boost that enhances maximum data-transmission distance and allows the integration of multiple sensors onto a single RFID tag.

These solar cells have the potential to power the sensors in bright outdoor sunlight and dimmer indoor conditions. Using alternative cheap and green materials will offer a new degree of freedom in powering the IoT devices and create more variety, feeding into more potential breakthroughs that could be life-changing for large groups of society.

Challenges in developing next-generation photovoltaic devices

The key to reducing the price-per-watt of thin-film PVs lies mainly in perfecting the fabrication technology: guaranteeing rapid fabrication, resource-saving, high-yield, and in-line large-area deposition of each layer of the solar cells at the lowest possible cost.

The 5GSOLAR team relies on developing non-toxic, earth-abundant, long-term stable PV materials and implementing cost-effective, robust, industrially scalable, rapid, and resource-saving technologies.

Two thin film fabrication technologies are under the 5GSOLAR spotlight

The chemical spray pyrolysis method qualifies for this task, with great potential to become the frontline technology. The solar cells under development, both the electron transport layer and the absorber layer, are deposited by the chemical spray pyrolysis method.

What is unique here is that the deposition process takes place in ambient atmosphere/air. On top of that, chemical spray pyrolysis is a highly resource-saving technology. For example, 1kg of antimony is enough to cover 5,000m2 of a substrate with a 100nm thick Sb2(S,Se)3 layer by spray.

Thus, remarkable PV fabrication cost and materials reduction can be foreseen. In the current stage of solar cell development, a solar cell stack comprising glass/conductive oxide/TiO2 (thickness ca 30 nm) /Sb2S3 (thickness ca 80 nm)/hole conductor/Au-contact result in a power conversion efficiency of 6%. The central stack of the solar cell is fabricated in less than 1.5 hours by the chemical spray pyrolysis method and adds little extra weight (<10 g/m2) to the window.5

Close-spaced sublimation (CSS) is the most straightforward, fastest, and resource-saving technology among physical thin film deposition methods. It is the dominant method in use for commercial CdTe thin film SC. The feasibility of this processing technique has been proven for Sb2Se3 on a laboratory scale, reaching an efficiency of ca. 8%.6,7 This means that CSS-developed Sb2(S,Se)3 and (Sb, Bi)2Se3 have enormous potential for a remarkable economic impact on rebooting the PV manufactories in the EU, as CSS is expected to enable the growth of high-quality Sb-chalcogenide TFs.

5GSOLAR has received funding from the Horizon 2020 Work Programme, H2020-WIDESPREAD-2018-2020, under grant agreement No. 952509.

The RENEW-PV Action of the European Cooperation in Science and Technology (COST)

In line with the broader scope of European green energy transformation and acceleration, researchers around the world launched a COST action CA21148 – Research and International Networking on Emerging Inorganic Chalcogenides for Photovoltaics – RENEW-PV.

The global challenge this network addresses is how to increase the proportion of power generated by earth-abundant photovoltaics, thereby reducing world carbon emissions and providing a green future for society.

RENEW-PV brings together leading and pioneering academic and industry researchers worldwide to stimulate further research development and deployment of emerging inorganic chalcogenide thin-film PV technologies.

The action aims to create a research and innovation networking environment that will exploit the high stability, low environmental impact, low carbon footprint, and high technological flexibility potential of emerging inorganic chalcogenide PV technologies.

RENEW-PV seeks to consolidate and strengthen the emerging PV ecosystem, generate and exchange knowledge, and enhance creativity and collaboration. It will deliver a portfolio of technological benchmarking to establish performance indicators that define a technical roadmap for developing a new type of PV technology capable of producing higher power densities and a broader application range than traditional Si-based PV.

It is now vital to bridge the knowledge gaps between different research groups focused on materials and device modelling, thin-film materials and processes development, solar cells engineering, and material and device characterisation.

RENEW-PV Action will promote research excellence and foster the career development of early-career researchers and doctoral students (following the gender balance principles) through networking, training, mentoring, and integration into PV research collaborations, contributing to the creation of jobs and the re-industrialisation of Europe in a low-carbon economy and green society.

Further information, including how to join the RENEW-PV network, can be found here: https://www.cost.eu/actions/CA21148/

References

- The European Strategic Energy Technology Plan, European Commission, 2014. Available: https://ec.europa.eu/energy/topics/technology-and-innovation/strategic-energy-technology-lan_en

- Critical Raw Materials, European Commission, 2017. Available:

https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en - Powell, D. M. et al., Energy Environ. Sci. 8, (2015) 3395

- W.M. Wheeler et al. One Earth 5 (2022) 1271

- J.S. Eensalu et al., Beilstein J. Nanotechnol. 10 (2019) 2396

- N. Spalatu et al., Sol. Energy Mater. Sol. Cells 225 (2021) 111045

7.T.D.C. Hobson et al., Chem. Mater. 32 (2020) 2621

Please note, this article will also appear in the thirteenth edition of our quarterly publication.