An environmentally friendly proprietary separation process will allow ElementUS to transform bauxite residue waste into valuable products that enable green technology.

Bauxite residue is a waste by-product in the alumina refining business. The more colloquial term for it is ‘red mud’ since it contains high concentrations of iron oxides. About 30 million tons of this red residue currently reside in tailings ponds in Gramercy, Louisiana, the home of Noranda Alumina’s 3,300-acre Alumina Refinery site.

What can you do with 30 million tons of red mud? As it turns out, a portion of this waste product contains valuable rare earth elements (REE) such as neodymium, yttrium, cerium, lanthanum and critical metals such as scandium. REE provide key performance attributes in a variety of industrial and consumer products, including batteries, magnets, refining catalysts, aircraft engines, electric vehicles, smartphones, digital cameras, computers, flat-screen TVs, lighting, and medical scanning equipment.

Critical metals like scandium are used in solid oxide fuel cells and lightweight alloys for the aerospace and automotive industry. Noranda Alumina’s residual bauxite has been confirmed to contain rare earth elements and minerals targeted by the US Defense Logistics Agency, along with titanium, iron and other minerals and metals valuable to US industry.

This potential is often locked up in the bauxite residue and has presented the alumina refining industry with a significant extraction challenge. The objective is to extract as much value as possible in an environmentally safe and economically viable way. This is where ElementUS Minerals, LLC, enters the picture with its no-waste solution.

ElementUS is a private company formed in early 2020 that plans to construct an on-site separation plant that will use a highly engineered, proprietary combination of processes to separate bauxite residue into its component materials, including several rare earth elements, iron, titanium and alumina.

The innovative approach proposed by ElementUS will not only provide an environmentally-friendly solution based on technically sound principles, but it will also be based on a no-waste philosophy that will eliminate all the bauxite residue from the site and, in the process, generate strategic value-added products.

“What’s appealing from a financial perspective is the fact that only about 20% of the total revenue value of the bauxite residue resides with the REE and critical metals,” commented Chris Young, Chief Strategy Officer of ElementUS Minerals. “The remaining 80% of the expected revenue will be derived from the downstream production of a variety of pigments, sorbents, and coagulants. These will provide ElementUS with a well-diversified product stream that will mitigate the risks associated with market demand fluctuations.”

Standing at the helm of ElementUS is Chief Executive Officer, Mr Joseph Carrabba. Mr Carrabba has over 30 years of executive experience in the natural resources and metals industries sectors. He spent over 20 years in executive leadership at Rio Tinto, holding positions in its North American, Australian, Asian and European operations.

“I am thrilled to lead this company and its critical initiatives as we help restore the environment and reduce the world’s dependence on rare earths from China,” Mr Carrabba said. “My work over the past decade has focused on sustainability and environmentally conscious industrial practices, and ElementUS is poised to continue that effort. By transforming industrial waste into rare earths and other essential elements for domestic use, we not only advance our country’s national and economic security, but we also benefit the environment

as well.”

The economic development plan

The current development plan is based on constructing a state-of-the art and environmentally- friendly reclamation, separation, and beneficiation facility at the Noranda Alumina site in Gramercy. The site is situated on the Mississippi River with access to key infrastructure for truck, rail, barge and ocean freight. The project would result in 200 new direct green jobs. Louisiana Economic Development estimates an additional 590 new indirect jobs would result, for a total of nearly 800 new jobs in Louisiana’s South East region and surrounding areas.

The government of the State of Louisiana has provided its support for the implementation of the project. The Louisiana Economic Development (LED) programme provides a significant incentive package. ElementUS is participating in the LED Quality Jobs Program, Louisiana Research and Development Tax Credit scheme, LED FastStart workforce development programme and Industrial Tax Exemption Incentive programmes.

“Incentivising sustainable green development projects is a fantastic way to attract innovators to improve all sectors of business,” said Mr Carrabba. “The practical incentives that the State of Louisiana will provide us represent important waypoints on our road to success.”

The Louisiana Public Facilities Authority (LPFA) approved a significant allocation of tax-exempt private activity bond issuance as part of the anticipated construction of the facility. This approval, and the subsequent Executive Order from the Governor of Louisiana on granting the bond allocation, represents a significant step forward for ElementUS.

“The LPFA is delighted to assist ElementUS with the financing for this exciting economic development opportunity and appreciate their investment in Louisiana,” commented James W. Parks II, President and CEO of the LPFA.

Over 30 years of feedstock already on-site

The Noranda Alumina plant, newly rebranded as Atlantic Alumina Company (ATALCO), has been operating since the 1950s and is now the only alumina refinery in the United States. Noranda imports bauxite from the company’s surface-mining operation in Jamaica. Bauxite ore is transported by ship to Gramercy, Louisiana, where the ore is unloaded and refined into aluminium oxide.

Noranda uses the Bayer process, which is a continuous-loop process that consists of digestion, clarification, precipitation, and calcination, to produce approximately 1.2 million tons of alumina per year in the form of wet-hydrate-cake, dry-hydrate, and smelter-grade alumina. These various alumina forms are used both for specialised products and as an intermediate step in producing aluminium. For every ton of alumina produced through the Bayer process, there is approximately one ton of bauxite residue (red mud). The waste bauxite residue is stored in six tailings ponds. The bauxite residue currently present in the Noranda ponds has accumulated over a period of more than 30 years.

Independent testing

ElementUS hired an engineering firm, RESPEC, to determine the quantity and composition of the bauxite residue stored in the ponds. It was determined that approximately 30 million dry tonnes of mineral-rich bauxite residue are easily accessible at the Gramercy site, and this material requires no further mining or crushing. An additional one million tons of bauxite residue will be generated each year by the ongoing operations occurring at the Alumina Refinery.

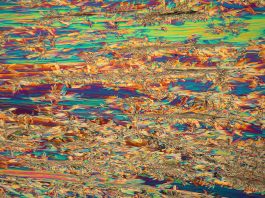

Bauxite residue samples collected by RESPEC were tested by the world-renowned Hazen Research Analytical Laboratories. The results indicate the bauxite residue is highly consistent and homogeneous. This makes it amenable to several well-established processing technologies that can be employed downstream to obtain saleable products.

ElementUS received independent validation of its proprietary separation technology from a globally and industry-recognised laboratory in Weissbach, Germany. The company has also engaged Techint Engineering and Construction to commence front end engineering design. Upon a final investment decision, construction could be completed within two years in a building phase to generate an estimated 2,200 construction-related jobs.

A zero-residue refining business

The totality of the bauxite residue fed into the ElementUS complex will be treated in such a way that not only high-value REEs and critical metals will be recovered, but several value-added products will be produced. These include:

- Sorbents – allow the absorption and recovery of contaminated water sources;

- Coagulants – water treatment coagulant in water purification systems;

- Iron oxide pellets and briquettes – used in steel production;

- Iron oxide pigments (IOP’s) – wide-ranging uses including concrete, industrial coatings, paint, plastics, and glass/ceramics;

- Titanium dioxide pigments – used in paints, plastics, paper, catalysts, ceramics, and textiles;

- Silica oxides – used for building product fillers, glass, cementing sand, ceramics, and abrasives; and

- Calcium carbonate – used in building materials, ceramics, latex, paper and in the oil and steel industry.

Finally, the by-products created from operations will be utilised. ElementUS will use a proprietary process to convert this waste into inert products ranging from basic to high-performance synthetic aggregates with commercial value.

The bottom line in transforming bauxite residue

ElementUS is implementing a game-changing, environmentally safe process that transforms bauxite residue into commercially viable and valuable materials with zero-waste.

The production of valuable REEs helps provide the United States with a US-based source of these strategic elements and critical metals. Currently, more than 90% of the world’s REE supply comes from China.

The new plant is expected to provide over 200 ongoing and highly skilled green jobs and nearly 600 indirect jobs. The plant construction, operations and eventual expansion phases will result in more employment opportunities. This will increase the long-term sustainability of the only remaining alumina refinery in the United States.

Please note, this article will also appear in the eighth edition of our quarterly publication.