A research team has innovated groundbreaking biodegradable circuit boards that look to solve the growing problem of electronic waste and may pave the way for future, fully disposable electronics.

Discarded electronics, including mobile phones, laptops, and tablets, are becoming a rapidly-growing source of electronic waste, as their components are usually challenging to recycle and do not degrade naturally. A promising method to reduce electronic waste is to design their components using renewable resources that can be responsibly disposed of easily.

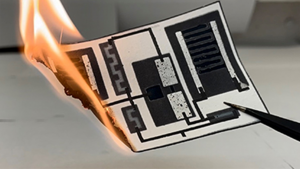

Emerging research published in ACS Applied Materials & Interfaces and funded by the National Science Foundation outlines a novel prototype circuit board comprised of a sheet of paper with fully integrated electrical components that can be burned or left to degrade. The innovation could potentially make electronic pollution a thing of the past.

The global landscape of electronic waste

Estimates from the WEEE Forum suggest that in 2021, there were 57.4 million tonnes of electronic waste – greater than the weight of the Great Wall of China – the heaviest artificial object on Earth. This was a significant rise from 53.6 million tonnes in 2019, and a 21% increase since 2014, with electronic waste forecasted to surpass 74 million tonnes by 2030.

In the US alone, despite more than 151 million mobile phones being recycled each year, approximately 416,000 are thrown away and end up incinerated or landfilled daily, with 40% of heavy metals in US landfills coming from electronic waste.

The majority of small electronics include circuit boards made from glass fibres, resins, and metal wiring. Unfortunately, these circuit boards are difficult to recycle and are usually bulky, which makes them ill-suited for use in point-of-care medical devices, environmental monitors, or personal wearable devices.

A promising alternative to this issue is paper-based circuit boards, which are easier to dispose of, cheaper, and more flexible. However, currently, these circuit boards require specialised paper or have traditional metal circuitry components mounted on a sheet of paper.

Advancing circuit boards

To overcome these drawbacks, the researchers endeavoured to create simple-to-manufacture circuitry that has all the electronic components wholly integrated into the sheet. The team developed a paper-based amplifier-type circuit that included resistors, capacitors, and a transistor.

Initially, they utilised wax to print channels onto a sheet of paper in a simple pattern. After the wax was melted and soaked into the paper, the researchers printed semi-conductive and conductive inks, which subsequently soaked into the areas not blocked by the wax. Next, they screen-printed extra conductive metal components and casted a gel-based electrolyte onto the sheet.

Credit: Adapted from ACS Applied Materials & Interfaces 2022, DOI:10.1021/acsami.2c13503

The researchers then performed tests on the resistor, capacitor, and transistor, demonstrating that they worked correctly. The final circuit board was highly flexible even after adding the components. To show its durability, the team demonstrated that the entire unit rapidly burned to ash after being exposed to fire. They believe this represents a significant step toward fully-disposable electronics, a milestone in reducing electronic waste.