The US Department of Energy’s (DOE) Argonne National Laboratory has been awarded over $6m to develop innovative technologies that focus on recycling used nuclear fuel.

Until now, the US has not previously recycled nuclear fuel, unlike some European countries such as France. Instead, most of the nation’s used fuel has been safely and securely stored at more than 70 reactor sites across the country. Roughly a quarter of these sites no longer have a reactor in operation.

However, used nuclear fuel can be recycled to make new fuel and by-products. More than 90% of its potential energy still remains in the fuel, even after five years of operation in a reactor.1

A very small fraction of the energy available in nuclear fuel is used during the production of nuclear energy. The amount that remains can be recovered and recycled to create a lot of electricity. The DOE’s Advanced Research Projects Agency-Energy (ARPA-E) estimates that the untapped energy remaining in used nuclear fuel, sometimes referred to as spent nuclear fuel, can generate enough clean energy to power more than 70 million homes.

Therefore, the DOE has decided to capitalise on these opportunities through two new projects to help the country get even more out of safe, clean nuclear power.

The Innovation Platform takes a look at how these projects will contribute to innovations in safe, clean nuclear energy.

The DOE’s role in recycling used nuclear fuel

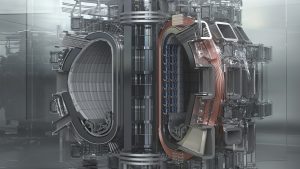

Nuclear energy is one of the largest sources of emissions-free power in the world, generating nearly a fifth of America’s electricity and half of its clean energy.

The DOE’s Office of Nuclear Energy (NE) is responsible for ongoing research and development (R&D) related to long-term disposition of used nuclear fuel and high-level radioactive waste (HLW), which are managed by the Office of Spent Fuel and Waste Disposition (SFWD).

SFWD sponsors work with national laboratories, industry, and academia to examine alternatives and conduct scientific research and technology development to enable long-term storage, transportation, and geologic disposal of used nuclear fuel and radioactive wastes.

SFWD research has included the investigation of SNF and wastes generated by existing and future nuclear fuel cycle options and technologies that minimise waste generation, improve safety, and complement institutional measures in limiting proliferation risk.

Closing the gaps in nuclear technology

ARPA-E awarded more than $6m to DOE’s Argonne National Laboratory to develop and demonstrate innovative processes and technologies that focus on recycling used nuclear fuel (UNF). The funding is awarded through the Converting UNF Radioisotopes Into Energy (CURIE) programme.

The two projects will demonstrate improved separation technologies to help the US get even more energy out of safe, clean nuclear power.

Nuclear energy is the source of approximately one-fifth of the total electricity used in the US, and it provided half of the nation’s carbon-free electricity in 2021. Improving electrochemical separation and other UNF recovery and recycling technologies could help nuclear energy do more. More efficient use of nuclear energy would significantly decrease domestic reliance on fossil fuels and the related greenhouse gases that contribute to climate change.

Moreover, it would reduce waste and produce new fuel for advanced reactors. This last benefit would lead to the deployment of new advanced reactors, which would provide even more safe, clean, and reliable electricity.

Krista Hawthorne, the pyroprocess engineering Section Manager in Argonne’s Chemical and Fuel Cycle Technologies division, is leading the effort. She commented: “Our partnerships with ARPA-E and industry are incredibly important to closing remaining technology gaps.”

What do the new projects entail?

Argonne will use ARPA-E’s funding to advance two nuclear fuel projects. The larger project will combine Argonne’s leadership in nuclear research and development with the experience of nuclear industry partners Oklo Inc. and Deep Isolation. Argonne will collaborate with Case Western Reserve University on both projects.

The larger project was awarded $4.9m. It focuses on increasing the efficiency and economics of nuclear fuel recycling processes. Argonne, Oklo Inc. and Deep Isolation are working to improve a process that converts UNF oxide fuel to a metal, that can then be processed to provide useable materials for advanced reactor fuel. The project will combine improvements in stable, next-generation anode materials and sensors used to control the process, which will maximise the amount of material that can ultimately be recovered.

“Improving the efficiency of fuel recycling processes will help recover and recycle valuable resource materials remaining in used nuclear fuel,” Hawthorne explained.

The second project was awarded $1.52m. With this project, Argonne researchers will develop, produce and test more efficient industrial chemical processing equipment to reprocess used nuclear fuel. The project lead is Argonne radiochemist Anna Servis.

State-of-the-art facilities that reprocess light water nuclear reactor fuels use equipment known as packed bed columns. Packed bed columns are tall canisters filled with a packing material that mixes the fluids flowing from one end to the other during chemical separations.

The team’s design instead uses PACERs (Packed Centrifugal Equipment for Radiochemical separations). PACERs are rotating packed bed contactors that are considerably more efficient than the columns. They use centrifugal forces much greater than the pull of gravity to boost the speed and efficiency of chemical separations. They are also notably smaller than the columns. For scale, the size difference can most closely be compared to replacing a water tower-sized packed bed column with a shed-sized PACER.

“Used nuclear fuel contains a treasure trove of raw materials, including energy-rich uranium, that can be recycled into new fuel, precious metals, and versatile radioisotopes,” said Servis.

She concluded: “Mining our existing UNF stockpiles reduces demand for non-renewable minerals and conserves resources for future generations.”

References

Please note, this article will also appear in the twelfth edition of our quarterly publication.