Drive System Design identifies the electrified propulsion systems that best meet its customers’ goals through a system-led approach and strategic partnerships.

Electric vehicles (EVs) can be less complex, requiring less maintenance and fewer parts than internal combustion engine (ICE) vehicles. But determining the most efficient and sustainable EV propulsion system, while also achieving specific company goals, is not a simple process.

There are many ways to move toward electrification. Across industries, there are plenty of different energy storage systems, motor topologies, and technologies being tested and implemented, with the manufacturing processes for each being developed in parallel.

The key to success is having a partner that is well-versed in full-system integration. One that understands the critical sub-systems and interactions that make an EV propulsion system deliver the intended attribute combination, whilst having an in-depth knowledge of the resources and techniques available to improve sustainability.

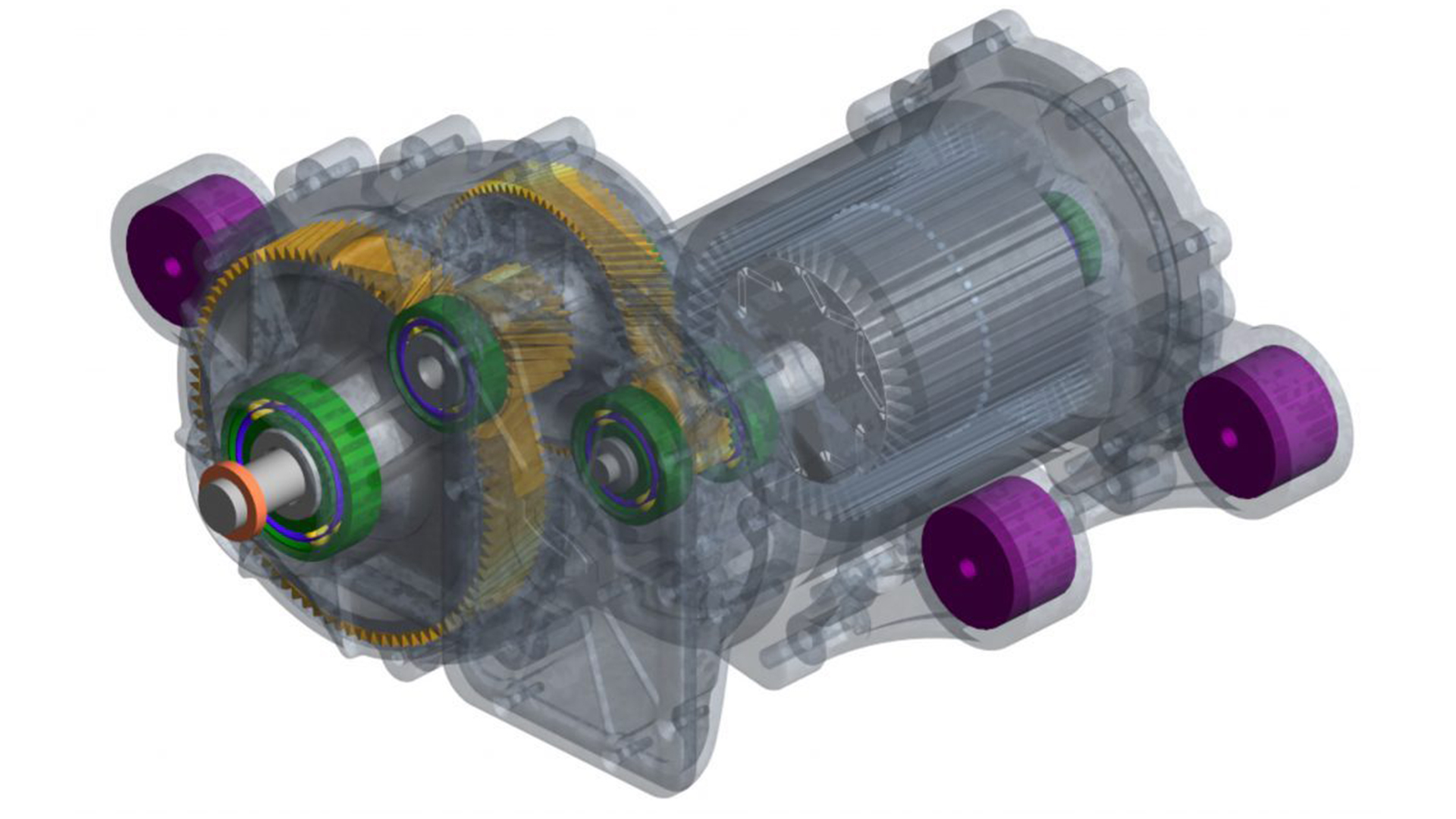

Drive System Design (DSD) specialises in the rapid engineering and development of electrified propulsion systems and associated technologies and has been helping a broad array of customers across industries better understand the electrified solutions that best meet their individual needs. Leveraging decades of experience and turnkey capabilities, DSD offers unparalleled proficiency in systems integration, simulation-led design, efficiency enhancement, development testing, and the analysis and control of transmission systems and electrified powertrains.

The company works collaboratively with automotive, commercial vehicle, aerospace, off-highway and defence OEMs, Tier-1s, and industry groups to help them pave the path that aligns with their respective environmental, attribute, and performance goals. When developing an electric propulsion system, there are many considerations to uncover the best path forward, including:

- What is the right attribute combination – efficiency, NVH, durability, weight, or cost?

- What is the application, duty cycle, and use case?

- How does the infrastructure of the application impact the vehicle or use case?

- How can new and/or existing sub-systems be integrated together to deliver an optimised propulsion system?

Simulation first

DSD is a simulation-led company, using a variety of modelling and analysis tools to simulate how sub-systems perform and interact before clients move too far into the resource and cost-intensive prototype manufacturing phase, where rework is most costly.

In recent years, the company has assisted mobility clients with swiftly identifying the best propulsion system makeup that meets their unique goals, using its proprietary Electrified Powertrain Optimisation Process (ePOP). The advanced software-based tool combines DSD’s extensive expertise along with its unique toolsets and processes to quickly analyse tens to hundreds of thousands of powertrain combinations against mass, range, cost, and efficiency, across multiple vehicle drive cycles, types, and segments.

A core purpose of ePOP is to understand how specific motors, inverters, and transmissions work together at an integrated system level versus an isolated sub-system optimisation approach. A highly targeted subset of powertrain configurations can be pinpointed based on this analysis.

Various combinations can be analysed, refining and focusing on data inputs that give detailed insight into attribute tradeoffs, such as power losses versus costs, to further hone in on the most suitable powertrain makeup. Motor topology, performance, ratio span and count, power electronics technology, power density, and more, can be mapped out using ePOP.

Beyond identifying the most efficient EV system, it is also important to consider whether there are more sustainable elements that should be considered. True, the push for electrification is rooted in the desire for a more environmentally-friendly world, but there is still more work to be done beyond committing to a fleet of EVs, aircraft, tractors, trucks and more. Even within the confines of engineering EVs, there is more that can be done, perhaps a more sustainable way of approaching EV design.

When it comes to sustainability, there are additional questions to consider:

- How to minimise the use of CO2 during the development process?

- What level of ease is battery and sub-system recyclability?

- What is the path to reduce rare earth material usage?

- Are supplier partners abiding by sustainability and carbon-neutral processes and initiatives?

Total cost of ownership and the environmental impact of the system can also be estimated in ePOP as well as trend predictions, such as forecasting the technological impact of changes in rare earth material costs, given that so many EV products will not come to market now, but in three to five years after they are first conceived.

The search for more sustainable materials

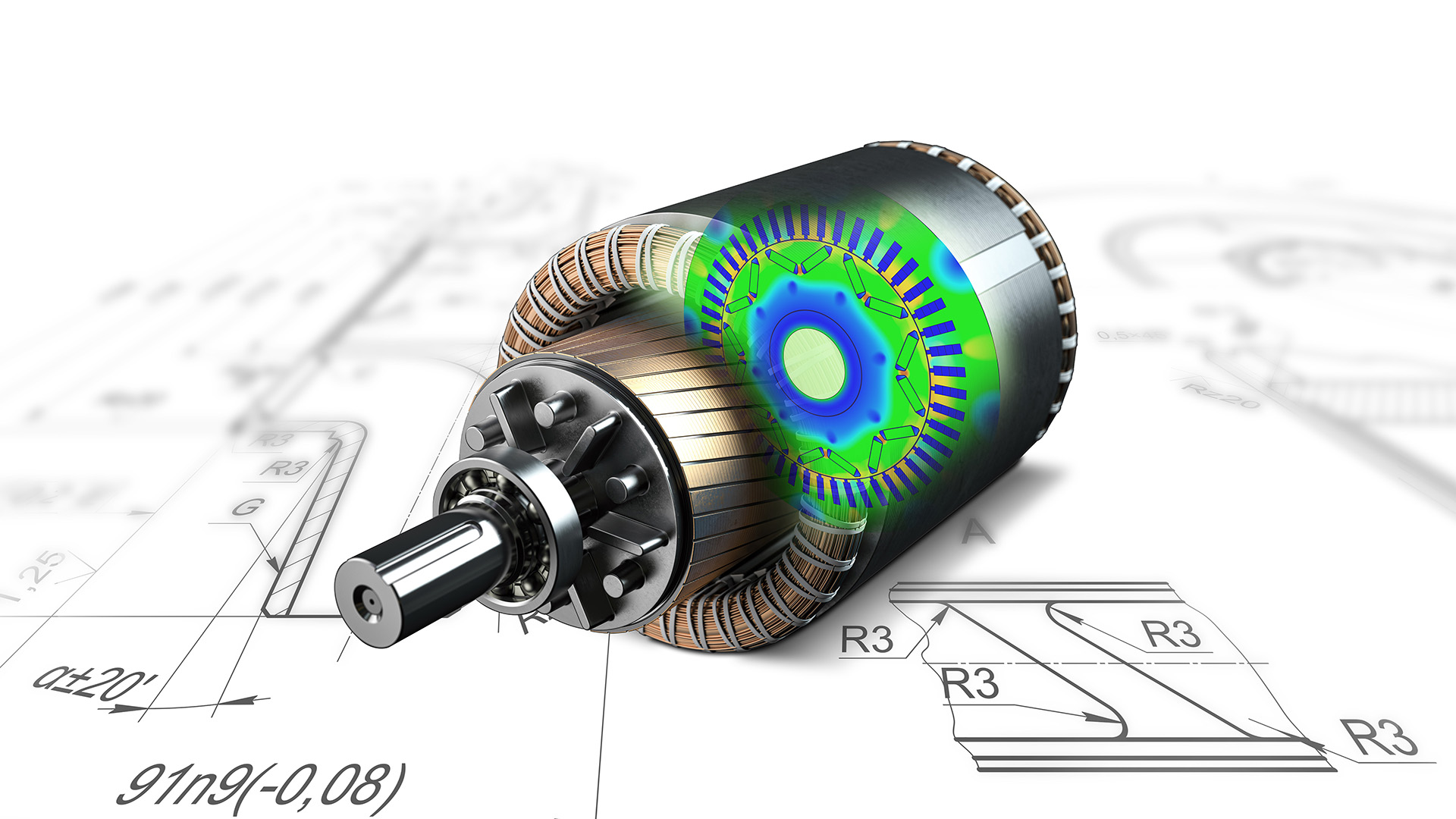

Most current propulsion systems incorporate electrical steel within permanent magnet machines, using rare earth materials and magnets. There is no doubt that there are significant performance benefits with rare earth materials, however, as electrification takes hold, these materials will become more expensive and politically harder to source and import.

To expand its sustainability initiatives, including minimising dependency upon rare earth materials, DSD has entered into a joint operating agreement with Alvier Mechatronics – an engineering service company with special competence in advanced materials and production methods for sustainable, high-volume applications – to provide sustainable electrified propulsion systems across automotive, commercial vehicle, off-highway, marine, and aerospace applications.

DSD will provide its simulation, prototyping, and validation expertise within the agreement while Alvier Mechatronics will bring its powder metallurgy and electromagnetic design capabilities to the partnership. Improving speed-to-market by combining metallurgical and electromagnetic phases of development with reduced prototype lead-time and sustainability improvements are core objectives of this collaboration.

One area that both partners believe has strong potential for offering more sustainable solutions is the use of soft-magnetic composite (SMC) materials, which can accommodate various motor topologies and has piqued market interest in recent years. These materials have the potential to increase the power density and efficiency of electric motors while also reducing cost and environmental impact. With Alvier Mechatronics and powder metallurgy giant Höganäs, DSD will help develop and deploy these materials for high-performance motors.

Traditionally, a vehicle’s stator has been formed with layers of cold-rolled electrical steel laminated together with an insulated coating between each sheet. The stator forms and enhances the electromagnetic field generated by the copper windings, and through the use of insulated layers, eddy current losses are reduced.

SMCs, on the other hand, start with pure iron particles made from high-quality scrap iron that has been melted and water-atomised then coated with an inorganic insulating material, instead of flat sheets. The physical and electromagnetic properties of the SMCs are consistent in all directions and form more of a three-dimensional structure compared to traditional laminated structures.

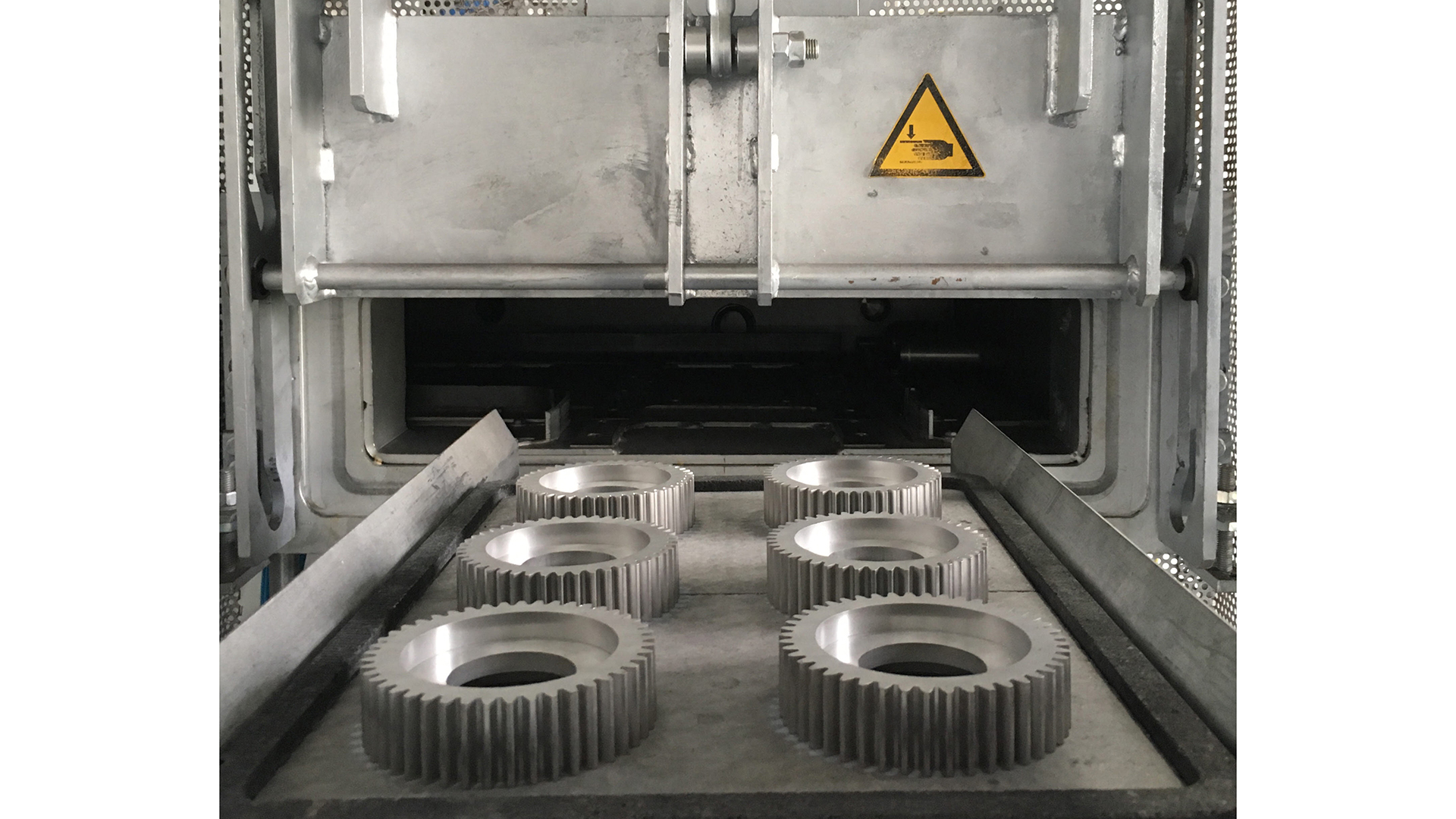

The SMC materials, developed by Alvier’s parent company Höganäs, are fed into a die cavity after being coated, where it is compacted using a single-axis punch. Afterwards, it is heat-treated to fine-tune its properties including stiffness, strength, and magnetic performance. The core is tailored to work most efficiently at a given frequency through the tuning process. While core losses can be worse for an SMC component at low frequencies (up to about 50 Hz), they can be considerably better at higher frequencies. This is ideal when combined with the high-frequency operation offered by wide bandgap devices for power electronics.

Additionally, SMC motors can be smaller and lighter for a given output than those using conventional steel laminates due to greater control over the field shape and frequency response. The stamping process used to create them is also inherently suited to high-volume production.

There are multiple advantages from production to implementation that the use of SMCs can offer depending on the use case, including:

- Decreased operational costs and simplified manufacturing;

- Greater recyclability potential;

- Decreased weight;

- Compact design resulting in package space savings;

- More design freedom compared to laminated solutions; and

- Reduced carbon footprint.

While its favourable attributes in terms of sustainability can lead to the improved total cost of ownership, SMC materials also have drawbacks. For example, this material tends to be more brittle than steel, limiting its usage for other elements of the propulsion system, such as rotors, where the electromagnetic benefits could bring even greater system performance. Higher currents can also be required to deliver the same torque at low magnetic field strengths due to the material’s lower magnetic permeability.

The unique characteristics offered by SMCs, and the ability to readily tune, adapt, and evolve both the material properties and the complete integrated system early in propulsion system development is a unique value proposition delivered by the DSD and Alvier partnership.

Through DSD’s system-level approach and application experience, the company can determine which applications are suitable for the use of these materials. In some cases, SMCs can even be used with steel laminates, delivering benefits from both materials.

The road to electrification is still being paved but it can be made far less bumpy by having the right partners involved early to help navigate system tradeoffs, material usage, and technical strategies to not only optimise system performance, but capitalise upon sustainability improvements as well.

Please note, this article will also appear in the thirteenth edition of our quarterly publication.