A Korean research team has pioneered revolutionary carbon fibre paper technology that can potentially enhance the durability and lifespan of lithium metal batteries for electric vehicles (EVs).

Developed by experts at the KIST Jeonbuk Institute of Advanced Composition Materials and the Gwangju Institute of Science and Technology (GIST), the breakthrough promises to elevate lithium metal batteries to new frontiers – eliminating the major limitations of the technology.

By employing carbon fibre paper as the anode material in lithium metal batteries, the team has achieved a significant milestone in advancing EV battery capacity and charge times, which will be essential to increasing the uptake of green technology to decarbonise the transport sector.

The study, ‘Construction of Hierarchical Surface on Carbon Fibre Paper for Lithium Metal Batteries with Superior Stability,’ is published in Advanced Energy Materials.

Lithium metal batteries could overcome EV limitations

EV technology’s most prominent challenges are concerns about range capacity, battery life, and charging times.

Traditionally, lithium-ion batteries have been the premier energy source for EVs, with battery packs ranging in power from around 30kWh in entry-level models to around 100kWh in more advanced EVs.

The driving capacity of current EV models ranges from around 130 miles on a full charge to over 350 miles in more expensive models. Moreover, the average lifespan for an EV is at least a decade, with battery warranties usually lasting 100,000 miles.

However, to fully replace conventional fossil fuel-powered transport, EV driving range, capacity, and charging will need to improve to cope with the daily demands of road users globally.

Lithium metal batteries have emerged as a promising candidate to replace conventional lithium-ion batteries due to their lithium anode demonstrating a ten times higher theoretical capacity than traditional graphite anodes.

Despite this, during the charging-discharging processes, lithium dendrites can develop on the anodes, which causes poor performance and short-circuiting. The team’s carbon fibre paper innovation looks to remedy these issues.

Carbon fibre paper optimises EV battery energy density

For their investigation, the researchers replaced a lithium metal-coated copper thin film with a carbon fibre paper containing lithium metal.

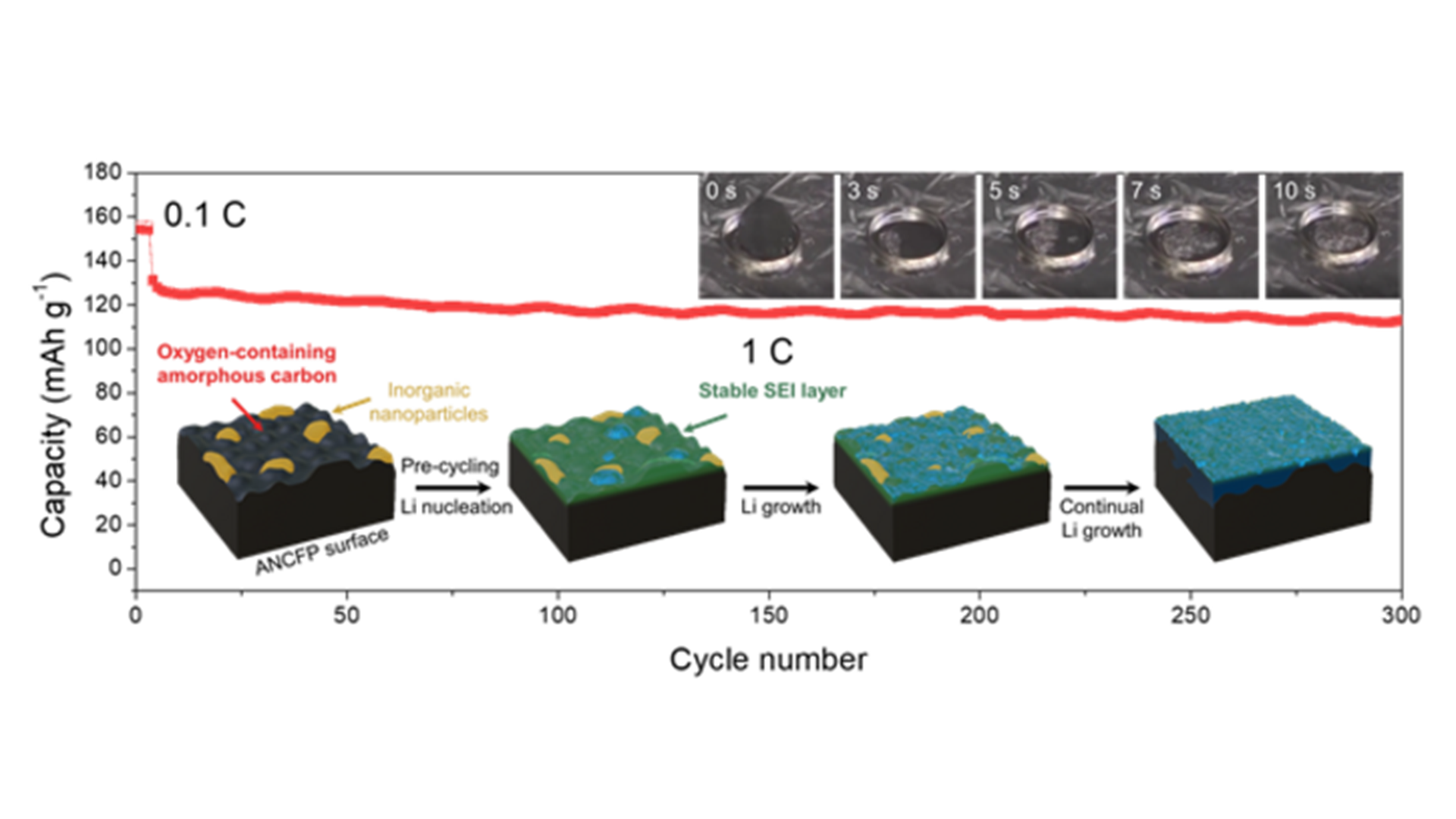

The carbon fibre paper comprised a hierarchical structure on the carbon monofilament that contained amorphous carbon and inorganic nanoparticles. This boosted the lithium affinity and stopped the formation of dendrites.

Whereas the copper thin film anode short-circuited after approximately 100 cycles, the carbon fibre paper anode exhibited outstanding cycling stability for 300 cycles.

It also demonstrated a high energy density of 428 Wh/kg compared to the 240 Wh/kg of the copper thin film. The manufacturing process is also much easier because the molten lithium can be easily infused into carbon fibre paper.

Dr Sung-Ho Lee, Head of the Center at KIST, who led the research, concluded: “Considering the five times lower density and lower cost of carbon fibre compared to copper, our proposed anode material is an important achievement that can accelerate the commercialisation of durable and lightweight lithium metal batteries.”