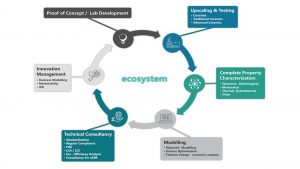

The LightCoce ecosystem is a one-stop-shop providing holistic services for the development of novel concepts in the fields of lightweight concrete and conventional and advanced ceramics.

LightCoce VISION

Aiming to provide a holistic approach for the development of beyond-the-state-of-the-art materials, the LightCoce ecosystem was established by 17 technology providers (consisting of research centres, universities, and high-tech companies). The concept for the creation of this ecosystem derived from the need to address the challenges that an idea faces in its route for transformation into a market-ready product capable of entering industrial production.

LightCoce technological services aspire to serve the needs of the construction, automotive and aerospace sectors by developing novel concepts in the fields of concrete, as well as conventional and advanced ceramics.

Addressing challenges in product development

The LightCoce ecosystem was therefore created to efficiently address the first and most significant bottleneck of novel product development: basic and advanced research and upscaling.

LightCoce offers companies and small and medium-sized enterprises (SMEs) the infrastructure and expertise not only for basic research, but also for pilot trials, providing to its users ‘lab-scale accuracy in a pilot scale’. This means that all upscaling services are supported by advanced monitoring and control systems, allowing not only a very firm control over the various parameters that affect the processes but also the detailed collection of measurements, in a way similar to what is happening in a lab.

A second important issue that companies can face during the development of an innovative material is the product’s complete characterisation, as well as the investigation for its compliance to the existing standards. In this aspect, LightCoce can offer two separate types of services: characterisation and standardisation. For the first type of services (characterisation), LightCoce experts can provide all the state-of-the-art characterisations of construction materials, according to international standard procedure guidelines (ASTM, EN, ISO), through its network of laboratories operating in five different countries: Sweden, Greece, Spain, Germany and Italy.

Although the majority of test methods for the characterisation of materials and structures are standardised, LightCoce experts also work on the development and improvement of non-standardised tests. For the second type of services (standardisation), LightCoce can assist the companies to navigate through the construction product requirements not only in the European market but also in the individual EU-member countries market.

The third bottleneck that innovative production faces is related to the identification of the market potential through dedicated market analysis, the creation of focused business plans and intellectual property rights (IPR) services. LightCoce can provide holistic support in this aspect, in a one-stop-shop along with other consultancy services, such as LCA/LCC and eco-efficiency. Furthermore, a forecast and optimisation of the performance of materials, production processes, and process energy consumption can be provided by the modelling services.

LightCoce aspires to be the future of high-tech support in the construction, automotive and aerospace environments, connecting great ideas with ingenious experts and state-of-the-art infrastructure. What remains to be seen is the impact that this venture will achieve in the European industry, if and how it will be able to transform innovation into industrial and commercial progress and, in the end, if Europe can win the industrial innovation bet.

The LightCoce ecosystem leverages the initiative of the HORIZON 2020 project, entitled ‘Building an Ecosystem for the upscaling of lightweight multi-functional concrete and ceramic materials and structures’, to shape a permanent, autonomous scheme that supports the needs of industry and especially of SMEs, which do not have the resources and infrastructure needed for research, and to become a pan-European access point for service delivery, innovation, and networking for the sectors under consideration.

LightCoce expertise

Basic research / upscaling / testing services

The LightCoce ecosystem offers a range of basic research, upscaling and testing services, provided by five pilot-scale facilities, where it is possible to produce materials in a scale closer to the industrial one, succeeding to cover the gap between laboratory development and full-scale production. These include:

- Transformation of ideas into materials and elements;

- Design of novel materials and elements;

- Preliminary basic assessment of the material properties produced during the pilot trials;

- Assessment of the upscaling potential of the product;

- Identification of possible problems related to the scale effect; and

- Finetuning of material formulation and synthesis process for the production of larger quantities.

For all thematic areas covered, LightCoce pilot-scale facilities address the upscaling / testing needs not only of conventional materials but also of materials with special requirements, such as the lightweight feature or additional nano-enabled functionalities.

LightCoce pilot-scale facilities are located in five European countries (Greece, Spain, Germany, Sweden, Poland) and are operated by well-known and prestigious research centres, universities and organisations (NTUA, RISE, THN, INOP, ITC-AICE). The advanced infrastructure of LightCoce pilot-scale facilities, in conjunction with highly qualified experts, guarantees a superior level of upscaling services.

Characterisation services

LightCoce offers a wide variety of analysis and test methods addressed towards materials, components, and products. Thanks to the network of partners with different expertise and specialisations, the characterisation activities cover different fields of application: concrete, ceramics, and nanomaterials.

Measurements and testing focus on four main areas of characterisation:

Structural and morphological properties concern the assessment of dimensions and surface quality, flatness of faces, density, and porosity, as well as chemical composition and mineralogy-crystalline content, size distribution analysis, microscopy, volume, and percentage of voids.

Mechanical testing evaluates the performance of differently sized and shaped samples under the application of various loads. This includes compressive, bending, tensile, shear, flexural and breaking strength as well as dynamic loads.

Thermal and hygrothermal analysis includes the evaluation of various applications of thermal conductivity, fire behaviour resistance, indoor emission by volatile organic compounds (VOCs), water absorption, durability of performance, and advanced thermal properties such as specific heat capacity and maximum service temperature.

Nano-enabled functionalities assess the performance of components with additional nanopowders and nanostructures in terms of mechanical and hygrothermal performance, as well as electrical conductivity, and easy-to-clean and self-sensing properties.

Modelling services

Modelling is a fundamental service provided by LightCoce that integrates materials’ modelling, process modelling and energy and exergy assessment. One can obtain a complete evaluation of the product, from the material to the environmental impact, and will be able to improve the flexibility and optimisation of the manufacturing system. The optimum solutions are obtained for different landscapes and scenarios offering a decision tool to support business plan and marketability.

LightCoce models lead to design novel materials and components. Mathematical models consider the different elements present in the manufacturing process to develop a holistic model of the whole process. The simulations and models are extended with in-depth evaluations that consider the resources and emissions of the system.

Technical consultancy services

The LightCoce ecosystem offers a holistic consulting approach to all technical aspects of innovative projects, from life cycle analysis and cost to health and safety issues, eco and energy efficiency, regulatory compliance etc., adjusted to each project’s special needs, through a wide network of experienced and specialised partners across Europe.

Innovation management services

Having a valuable product is important but it is definitely not enough in today’s competitive market. Especially when dealing with new technologies or disruptive innovations, the support by highly specialised innovation management services is crucial. Innovation management focuses on services that aim to facilitate the market uptake and exploitation of the products and technologies reaching the LightCoce ecosystem, such as market analysis, business modelling and planning, and IPR support.

LightCoce NETWORK

The LightCoce ecosystem is supported by 17 highly specialised service providers along Europe, forming a strong network of competences along the entire LightCoce value chain, matching the demands of industry.

Academic partners: National Technical University of Athens – Greece, Technical University of Nurnberg – Germany, University of Padova – Italy

Research institutes: ITC-AICE – Spain, Łukasiewicz Research Network – Metal Forming Institute – Poland, FIW Munich – Germany, RISE – Sweden

Companies/organisations: ADVANCED MATERIAL SIMULATION (AMS) – Spain, STAM – Italy, Hellenic Chapter of ASHRAE – Greece, EXELISIS – Greece, AXIA Innovation – Germany, IDENER – Spain, ZER0-E – Netherlands, SUSTAINABLE INNOVATIONS – Spain, ISQ – Portugal

Please note, this article will also appear in the fourteenth edition of our quarterly publication.