The Plastics2Olefins project is paving the way for the industrialisation of high-temperature pyrolysis for circular olefins production.

Plastic waste has become one of the most pressing environmental challenges of our time. Despite efforts to recycle and reduce plastic consumption, a significant amount of plastic still ends up in landfills, oceans, and natural habitats. This not only poses a threat to wildlife and ecosystems but also contributes to the depletion of finite resources. Globally, 359 million metric tons of plastic were produced in 2018, with Europe producing 17% of this. In the same year, 29 million metric tons of plastic waste was generated in the European Union (EU) and only a third of this was recycled.

While sorted and pure plastic waste can be recycled relatively easily using mature recycling technologies, a major problem is the recycling of unsorted waste. This holds a large share of valuable carbon feedstock but is currently either landfilled or energetically valorised (for example, incinerated), producing greenhouse gas emissions instead of recovering the precious carbon feedstock contained.

Hence, there is a need to develop new technologies that can valorise not only unsorted plastic, but also other waste in large amounts, to yield material streams that can replace fossil material streams.

Unlocking the potential of plastics and pyrolysis

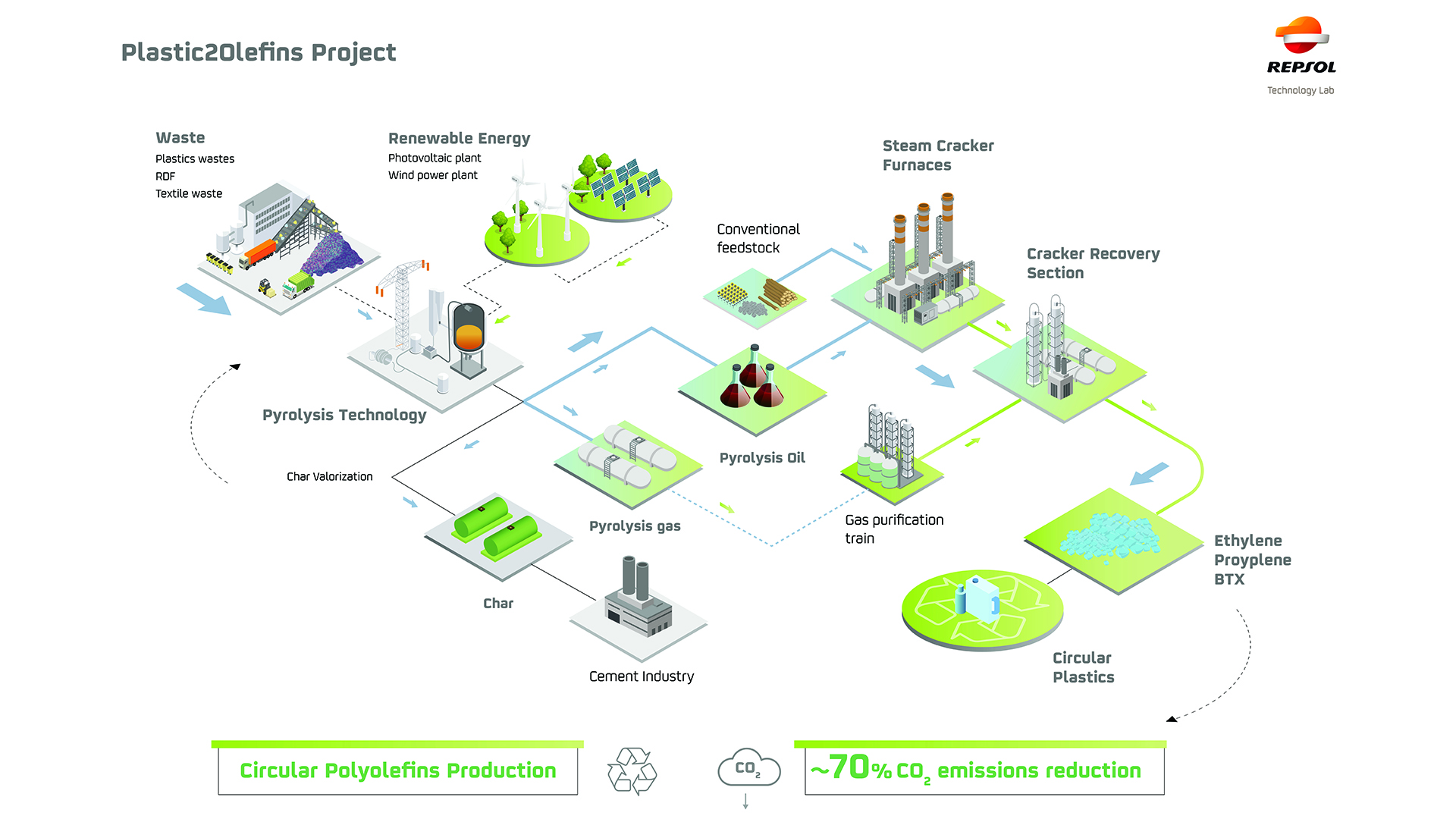

One promising technology to recycle unsorted heterogeneous plastic waste is pyrolysis – a chemical process to heat plastics and cause them to break down into various products such as pyrolysis oil, syngas and char. So far, traditional low-to-medium-temperature pyrolysis primarily yields liquid oil, which must undergo further processing at elevated temperatures in a furnace known as the steam cracker to produce olefins. Olefins are essential hydrocarbon compounds used in the production of plastics, chemicals, and fuels, making them a valuable resource for various industries.

In contrast to traditional approaches, the Plastics2Olefins project focuses on high-temperature pyrolysis, generating a pyrolysis gas stream rich in light olefins, which can be seamlessly integrated downstream into the steam cracker furnace. However, the use of high-temperature pyrolysis for plastic waste recycling has not yet become an industrial practice since gas treatment and integration present a great challenge.

By bringing together experts from industry, academia, and research institutions to develop advanced technologies capable of transforming plastic waste into valuable olefinic products, the Plastics2Olefins project will address this challenge. It will design, build, and run a demonstration plant for recycling unsorted plastic waste at Repsol’s industrial site (Spain), which will be digitalised and run on 100% renewable energy.

Rebeca Yuste, Technical Advisor for Circular Economy Process Design at Repsol and Project Coordinator, said: “The project’s goal is to significantly cut down greenhouse gas emissions over the product’s entire lifecycle, with an expected reduction of 70-80% compared to incineration and current plastics recycling methods.”

This effort is essential in helping the EU achieve its climate neutrality target by 2050 and paving the way for commercialisation and widespread adoption of recycled plastic feedstock as a substitute for fossil resources.

The Plastics2Olefins approach

The Plastics2Olefins project will be developed using a two-step approach, first by adapting and testing a scaled pilot plant at Repsol Technology Lab to optimise the components and process conditions. Finally, a full-scale industrial demonstration plant at Repsol’s industrial site will be operated in a six-month validation campaign in 2027.

To optimise the carbon footprint of such a plant, the project will design and construct the plant to be fully electrified by renewably-generated electricity. The project will also deliver a concept for renewable energy integration and, with the use of batteries and an Energy Management System (EMS), a 100% renewable energy supply will be ensured.

Coupled with this, a digital twin of the pilot plant will be developed to model the process dynamics of the whole unit, thereby enabling a twin transition. The digital twin will simulate the operating conditions and enable process scaling rules for a different feedstock and/or olefins-rich syngas throughput. It will also identify risks and mitigation measures and provide decision-making support. With the involvement of end users of the products, plastics, and char, as well as waste providers in the project, the full value chain and lifecycle of plastics will be covered, to prepare grounds for the broad application of the technology.

During the stage of pilot testing, validation, and optimisation, the pre-processed waste will first be tested at the facilities of project partner ETIA in Norway, where a small-scale pyrolysis unit is already located. In parallel, Repsol is building a pilot plant of the whole value chain at its technology laboratory in Spain. The pilot plant, with a capacity of ten kilograms per hour, will be used as the basis for the testing, validation, and optimisation of the entire recycling process, which will then be scaled up to the demonstration scale. All the processes will be tested and validated in the pilot plant at first.

Since difficult-to-recycle mixed waste fractions are used as feedstock in the Plastics2Olefins project, the produced gas contains multiple different impurities that are absent in current plastic production systems relying on fossil-based feedstocks. The new impurities originating from waste processing must be removed, and novel methods for cleaning the streams must be created to enable the full circularity of plastic waste.

One year into the project, the test results regarding many of these new impurities have been promising. Ville Nikkanen, downstream optimisation expert of project partner VTT, said: “We have been able to remove most of them. One of the objectives is to deliver completely purified gas as the Plastics2Olefins project will demonstrate the value chain from waste plastics to virgin-quality plastics.”

Following the validation and optimisation of the Plastics2Olefins technology at pilot scale, the demonstration plant will be designed and built according to conventional engineering workflow, but innovative engineering solutions will be developed and applied as required. The design basis and conceptual engineering broadly set the outlines of the plant and are succeeded by progressively detailed engineering which will provide all the information and data required for the procurement, construction, and operation of the demonstration plant.

Near the end of the construction, commissioning of the plant will bridge the gap between construction and the start of plant operation. Commissioning is a critical stage to hand over a safe, efficient and operation-ready facility. After commissioning the plant, a six-month operation campaign is planned in an industrial and integrated process.

Collaboration and future prospects

The Plastics2Olefins project exemplifies the power of collaboration between various stakeholders, and across the whole value chain of plastics recyling. It also highlights the importance of working together to advance technology and create a holistic approach to plastic waste management. By transforming plastic wastes into a valuable resource, the initiative aligns with the principles of the circular economy, where materials are reused, recycled, and repurposed to minimise waste and environmental impact. This will significantly contribute to a sustainable economy and will fulfil the aims of the European Green Deal.

The work of the Plastics2Olefins project will be an important contribution to the EU’s aim of climate neutrality by 2050 and set a pathway for the commercialisation of circular plastic replacing fossil feedstocks.

This project has received funding from the European Union’s Horizon Europe Research and Innovation programme under Grant Agreement No 101058032.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.