The shift to electrification across the automotive sector has intensified moves to improve battery system technologies to facilitate mainstream EV adoption.

The selection of a thermal management system is key as it dictates the operational limits of the battery pack and its performance under failure scenarios. Castrol have carried out significant research into the thermal propagation of battery modules with different thermal management approaches to develop their range of Castrol ON EV Thermal Fluids for immersion cooling.

This latest work compared battery cooling via indirect water-glycol baseplate cooling with the increasingly popular immersion cooling. Indirect cooling with water-glycol is already well established as the major cooling concept used in today’s EV architectures, due to considerable technology carryover from internal combustion engine cooling systems. However, immersion cooling is now being seen as more effective in tackling temperature management requirements during fast charging of new-generation EVs and improving performance of premium EVs.

Much of the previous work within the industry of immersion cooling has focused on cylindrical cells given their ease in adopting immersion cooling. However, Castrol’s latest work focused on demonstrating immersion cooling’s performance under failure scenarios with prismatic cells considering their use by major automakers such as VW, Tesla, Stellantis.

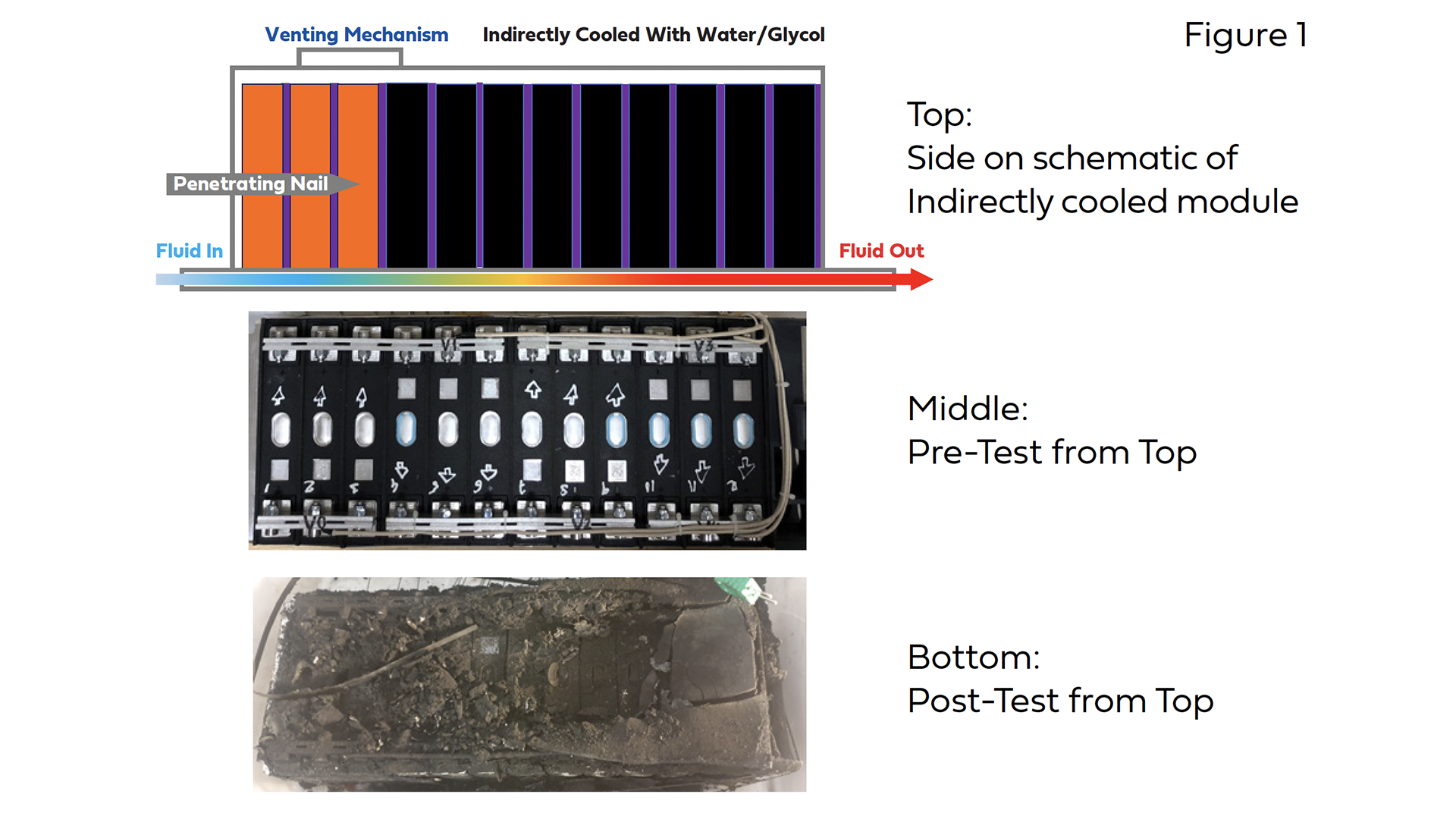

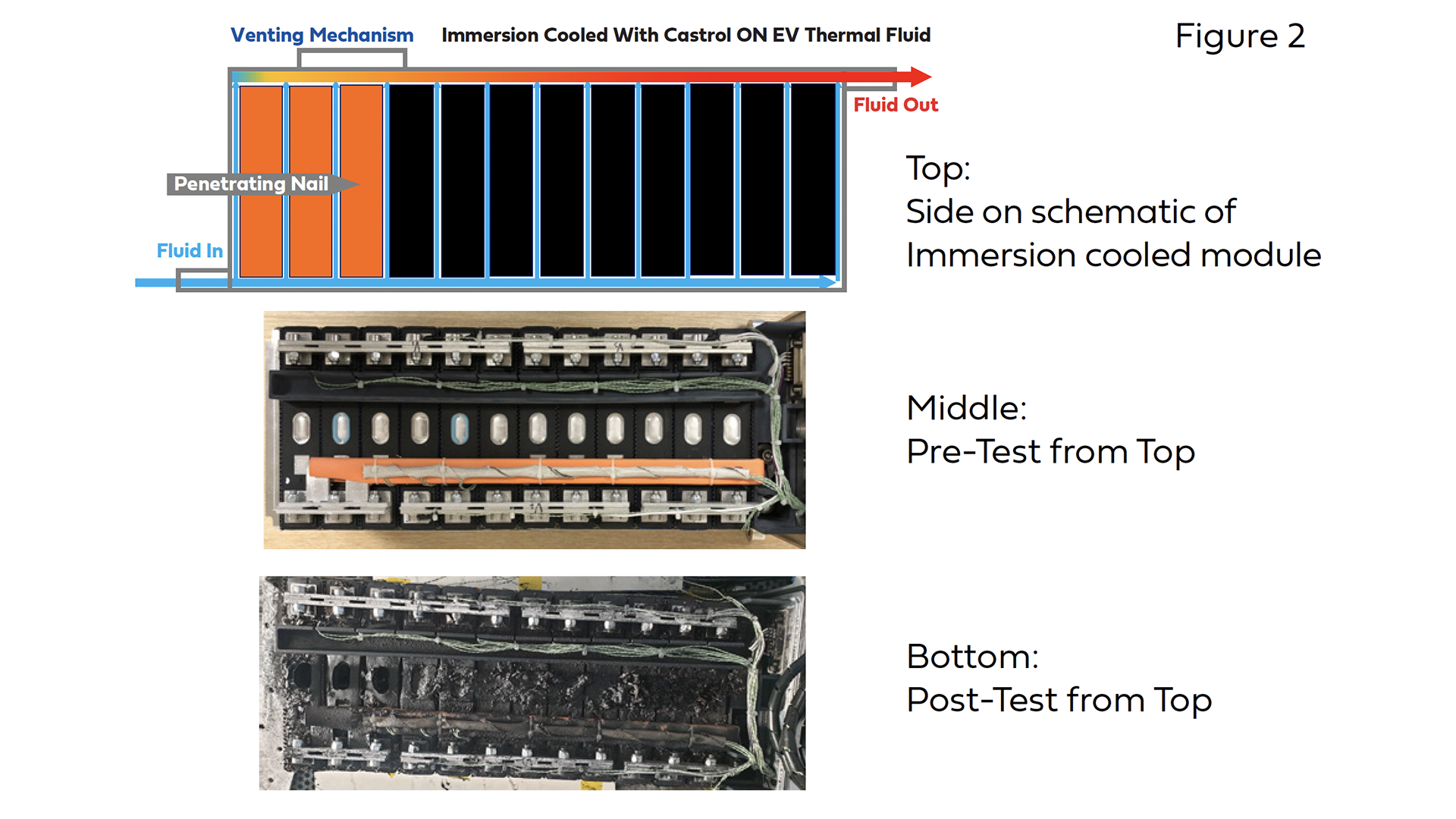

To demonstrate the effectiveness of immersion cooling with prismatic cells, an indirectly and an immersion cooled module were designed, consisting of 12 x 50Ah NMC prismatic cells each with a 2mm intercell distance. In the case of indirect cooling, this gap is filled with an aerogel material, whilst in the case of immersion cooling Castrol ON EV Thermal Fluid is circulated between the cells. By using the same intercell distance the two approaches can be compared based on the same volumetric energy density, which is a key metric for battery packs as it equates to the range of an EV.

To determine the performance of each approach under an extreme failure scenario, a nail penetration method was used to initiate the thermal runaway of the 3 cells at the end of the module.

Thermal runaway can lead to thermal propagation, where heat from the damaged cell or cells is transferred via convection and conduction to adjacent cells, a process that can potentially lead to the destruction of the entire battery pack.

During testing, the indirect minimodule suffered a catastrophic failure where the whole module was destroyed.

The two adjacent cells to the punctured 3 entered thermal runaway within a minute, with the remaining cells in the module sequentially entering thermal runaway as the propagation continued across the module; the whole process took just 15 minutes.

By contrast, the immersion cooled module proved effective in mitigating thermal propagation, with no cells entering thermal runaway except the 3 punctured cells, as evidenced by measurements during and after the test. This was attributed to the improved heat dissipation possible with immersion cooling. Effective heat dissipation is

a combination of vent gas management and the fluid conducting heat away from the damaged cell.

Castrol ON EV Thermal Fluids are developed to help avoid the risk of thermal propagation by directly cooling the individual cells, where high temperatures can cause irreversible failure as a result of overcharging or short-circuiting. With immersion cooled systems, thermal events of individual cells are better thermally managed.

Therefore, if they occur, they can be quenched at source –unlike in indirectly cooled systems.

Castrol ON Thermal Fluid is part of a family of Castrol ON products, which include Castrol ON EV Transmission Fluids and Castrol ON EV Greases. Castrol’s e-Mobility team continues to optimise thermal management performance through joint co-engineering programmes with partners, anticipating the multi-faceted technical challenges resulting from ever-increasing demands for greater battery and powertrain performance.

Please note, this article will also appear in the 18th edition of our quarterly publication.

![EV_THERMAL_HARE_TORTOISE_12K_FLAT_RGB_KV_INN_300x300[17] Castrol](https://www.innovationnewsnetwork.com/wp-content/uploads/2024/05/EV_THERMAL_HARE_TORTOISE_12K_FLAT_RGB_KV_INN_300x30017-696x392.jpg)