Researchers at the University of Chicago Pritzker School of Molecular Engineering (PME) have created a new method for sustainable lithium extraction.

Whereas traditional methods focus on lithium from rock ore or brine, the novel lithium extraction process focuses on more dilute and common sources.

The new method leverages certain particles of iron phosphate to pull lithium out of dilute liquids efficiently.

This includes seawater, groundwater and flowback water left from fracking and offshore oil drilling.

The new sustainable lithium extraction method could prove pivotal in diversifying and maximising lithium sources as demand for electric vehicles (EVs) increases.

Chong Liu, senior author of the research, explained: “Right now, there is a gap between the demand for lithium and the production.

“Our method allows the efficient extraction of the mineral from very dilute liquids, which can greatly broaden the potential sources of lithium.”

New frontiers in lithium extraction

Liu’s team has developed a novel method for extracting lithium from dilute liquids by isolating it based on its electrochemical properties, utilising crystal lattices of olivine iron phosphate.

Lithium is drawn into the spaces within olivine iron phosphate columns due to its size, charge, and reactivity, akin to water absorption in a sponge.

Importantly, when the column is optimally designed, sodium ions, also present in briny liquids, are excluded or enter the iron phosphate at significantly lower levels.

Impact of particle variation on selectivity

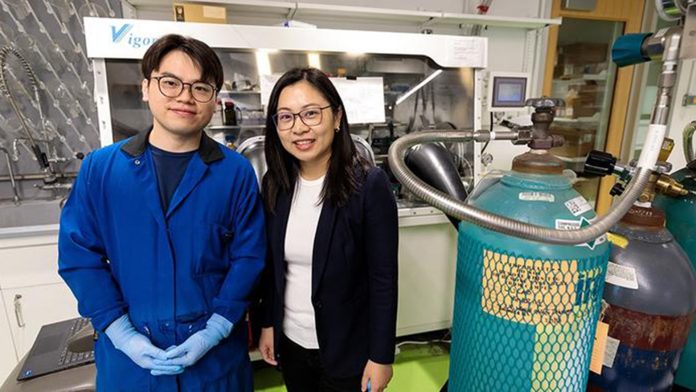

Liu, along with her colleague Gangbin Yan, a PME graduate student and first author of the study, examined how variations in olivine iron phosphate particles affect their ability to selectively isolate lithium over sodium.

The team synthesised olivine iron phosphate particles using diverse methods, resulting in sizes ranging from 20 to 6,000 nanometres.

These particles were categorised based on size and used to construct electrodes for lithium extraction from weak solutions.

Their findings revealed that when iron phosphate particles deviated from the optimal size range, both too large or too small, they allowed more sodium intrusion, resulting in less pure lithium extraction.

Commercial implications

The study emphasises the importance of producing olivine iron phosphate at the ideal particle size for electrochemical lithium extraction, which is crucial for advancing its commercial applications.

The team is confident that their new method could play a significant role in reinforcing lithium supply chains.