Set for rapid growth, Brazilian Critical Minerals is well positioned to benefit from nine large REE-focused tenements near Apuí Town.

Rare earth elements (REEs) are a group of 17 chemically similar elements that are crucial to modern technology and the global economy. Despite their name, these elements are relatively abundant in the Earth’s crust, but they are rarely found in concentrated forms, making their extraction and refinement both challenging and costly. The unique chemical and physical properties of REEs make them indispensable in a wide range of applications, from advanced electronics and renewable energy technologies to defence systems and medical devices.

The significance of rare earth elements lies in their ability to enhance the performance of various materials and components. For example, neodymium is a key component in powerful permanent magnets used in electric vehicles, wind turbines, and consumer electronics. Similarly, elements like yttrium, europium, and terbium are essential in the production of phosphors for LED lights and display screens, enabling high-efficiency lighting and vibrant colour displays.

As the world transitions toward cleaner energy and more advanced technologies, the demand for REEs continues to grow. However, the supply chain for these critical materials is complex and concentrated in a few geographic regions, leading to concerns about resource security and sustainability. The strategic importance of REEs has prompted many countries to invest in developing alternative sources, improving recycling techniques, and innovating new materials that can reduce dependency on these elements.

Australian-based exploration company, Brazilian Critical Minerals, is a key player in developing a rare earth supply chain with its developments in Brazil.

Brazilian Critical Minerals discovered two clay-hosted rare earth projects in the Apuí region of northern Brazil during 2023. The Ema project was discovered in May 2023 and by April 2024, the initial inferred JORC compliant Mineral Resource Estimate determined the Ema project was one of the largest of its type in the world.

China now dominates worldwide control over the production of rare earths through each key processing step and thus the price of the final products as well. The end product of the rare earth supply chain is permanent magnets, which currently have no viable material substitute and therefore remain irreplaceable components critical in the manufacture of most electrical systems and goods built today and, more importantly, in thousands of military defence systems and applications.

Their necessity means that a supply of these metals must be secured long-term. However, for countries in the Western world, this is currently a major challenge. Western countries are reliant on China for the refining of REEs, with the country dominating 90% of the processing and supply for these critical metals. Critical mineral geopolitical tensions of late, mean that those rare earth deposits which remain independent of China will play a key role in allowing for the vital downstream supply chain to establish and play a key role in the green energy transition.

Brazilian Critical Minerals boasts ownership of two major projects, Ema and Apui, which cover a vast expanse of over 700 km². Bolstered by the acquisition of nine exploration licenses, the company has demonstrated a commitment to strategic expansion. The initial leach testing, specifically with ammonium sulphate, has yielded world-class results, confirming the presence of ionic rare earths in these projects.

Positioned in a notably underexplored region, these initiatives hold the promise of establishing a new rare earth district, emphasizing Brazilian Critical Minerals’ pivotal role in uncovering valuable resources in untapped territories.

Listed on the Australian Stock Exchange, Brazilian Critical Minerals is a rare earths exploration company with aims to establish supply via its rare earth exploration projects in Brazil. Its flagship project, Ema, in the Apuí region is a very large fully ionic extractable clay rare earth deposit which is able to generate very high recovery levels of the key magnet rare earth elements neodymium and praseodymium (NdPr) and terbium and dysprosium (DyTb).

To find out more about the potential of this project, and the company’s plans for the future, Innovation News Network spoke to Brazilian Critical Mineral’s Managing Director Andrew Reid.

Why are rare earths so important?

They’re not actually that rare, but their importance to almost all modern technologies cannot be overstated.

Rare earths are a group of 17 metallic elements that can be found on the bottom of the periodic table. Fifteen of these elements are members of a group called lanthanides; the other two elements, scandium and yttrium, are located elsewhere on the periodic table but share similar chemical properties.

These elements have unique characteristics that make them critical components in the development of modern technology. Their unique physical and chemical properties make them arguably indispensable for modern life and are critical for the transition from fossil fuels to green power.

Rare earth pricing

Rare earth pricing is often referenced to Chinese official market prices, which are often difficult for outside vendors to achieve. The Chinese 13% value added tax is a subsidy for the export of Chinese post-metallic REE magnets and magnetic dependent component assemblies, such as REE magnet motors. This VAT is reflected in global pricing, as global REE pricing is set by China and reflects China’s VAT.

What is an ionic clay rare earth deposit?

Ionic clays potentially represent the most sustainable type of rare earth element deposit. Low-radioactivity with low CAPEX requirements, ionic clays are also the only type of deposit that contains important quantities of both light and heavy rare earth elements.

Unfortunately, and for a long time, economic deposits outside of China and Myanmar have been few and far between, but now they have been discovered in abundance in Brazil.

This type of ore is formed due to physical, chemical, and biological weathering of REE‐rich granitic and volcanic rocks under warm, humid, slightly acidic conditions in subtropical zones. Weathering crusts are up to 30 m deep, and depending on the nature of the original host rocks, the general components of the weathered ores are kaolinite, halloysite, and mica.

Considering the geological and climate conditions for the formation of REE‐bearing weathered ores, there is no reason to limit the occurrence of this type of deposit within Chinese borders. While China actively pursues and develops this type of resource to commercially produce REE, recent geological surveys have led to the discovery and investigation of similar ion adsorption deposits in Brazil, and in 2024, the Serra Verde ionic clay mine came into production.

The discovery of ionic clays in Brazil represents both an opportunity for investors and the chance to develop a more stable, diversified global supply chain for rare earth elements. Clay deposits containing physically adsorbed lanthanides are substantially lower in grade than other types of REE mineral resources; however, their abundance in subtropical regions and their existence as surface layers require low mining and processing costs, which now make them economically important sources of rare earths.

Leaching technologies for the ionic clays

Ionic adsorption clays contain anywhere between 500 – 3,000ppm rare earths, out of which 40‐90% occur as physically adsorbed species recoverable by simple ion‐exchange leaching. The ion‐adsorption clay deposits are the result of in‐situ lateritic weathering of rare-earth-rich host rocks (granitic or igneous), which lead over geological times to the formation of aluminosilicate clays.

These very fine mineral particles have the capability of adsorbing lanthanide ions released/dissolved during weathering. Sub‐tropical climates present ideal conditions for this lateritic process to occur. The best example of this formation process exists in Southern China (latitudes 24‐26°N), where many such deposits are known to exist. Despite their low grade, ion‐adsorption clays account for ~ 35% of China’s total REE production.

In the typical procedure, the ores are leached with concentrated inorganic salt solutions. During leaching, the physiosorbed REE are relatively easily and selectively desorbed and substituted on the substrate by the monovalent ions and transfer into solution as soluble sulphates or chlorides. Solubilised REEs are then usually selectively precipitated and subsequently converted to rare earth oxides.

Ema project

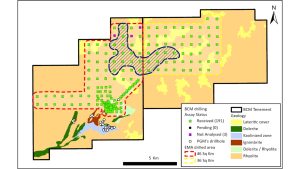

The Ema project is located in the State of Amazonas in Brazil (Fig. 2). The discovery of rare earths at Ema was announced in May 2023, with its maiden MRE announced just one year later in April 2024.

The EMA ionic REE project (Ema and Ema East leases) is unique amongst Brazilian REE projects in that it shares almost identical characteristics with the ionic REE deposits developed over felsic volcanic rocks in southwest China, the world´s largest known ionic clay region.

The project comprises 189 km2 of felsic volcanic over which 194 auger holes totalling 2,749 metres have been completed to date (Fig. 3), covering 82 km2 (<50% of available area).

Exploration drilling has been conducted with hand-held augers to date, which offers the advantage of low-cost, rapid deployment and mobility. One key constraint of auger drilling is the depth limitation, with the deepest holes, generally containing the highest-grade results, drilled to ~20m, with all holes stopping upon encountering the fresh rhyolite bedrock.

Most of the exploration to date has been conducted across hill slopes, on widely spaced (800m) centres, with limited drilling in the valleys and foothills. Future planned drilling in these limited areas could potentially facilitate penetration into higher-grade zones at depth. The entire enriched zone in Ema East is similar in grade and thickness to that at Ema, contained within the 10 metres of regolith sitting directly above the saprock/fresh rock interface, which shows a clear increase in grades.

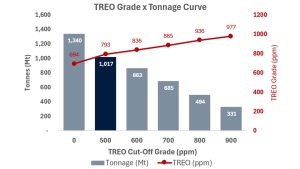

This enrichment of higher grades at the base of the regolith profile highlights an opportunity to potential target better mineralisation within this saprock zone. The current estimated “average grade” of the lower horizon within a 12km2 high-grade zone is 1,048ppm TREO, based on a cut-off of 700ppm TREO combined with NdPr >100ppm (Fig. 4).

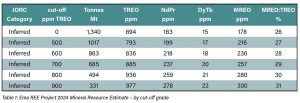

Ema mineral resource estimate

A set of Inferred Mineral Resources was estimated for the contained rare earth elements in the Ema project constrained by different cut-off grades by the consultancy group GE21 Consultoria Mineral Ltda (GE21) and reported in accordance with the JORC Code (2012) (Table 1) and (Fig. 3).

Geology and mineralisation

The REE mineralisation at EMA is contained within the tropical lateritic weathering profile developed on top of felsic volcanic and volcaniclastic rocks (rhyolites and ignimbrites).

The REE mineralisation is concentrated in the weathered portion of the profile where it has dissolved from primary rare earth minerals such as monazite and xenotime, migrating downwards through the regolith profile where it is adsorbed on to the neo-forming fine particles of aluminosilicate clays (e.g. kaolinite, illite, smectite). This adsorbed REE is the target for extraction and production of REO.

Drilling techniques

Auger drilling was completed by a hand-held mechanical auger with a 3” auger bit. This is an open-hole technique drilled vertically and not oriented. The average hole depth at Ema to date is only 15m.

The maximum depth achieved with the powered auger was 31m, and this was only achievable if the hole did not encounter fragments of rocks/boulders, etc., sitting within the weathered profile and/or the water table. Final depths were recorded according to the length of the rods in the hole.

In-situ leaching

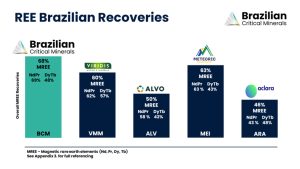

Work recently completed in the lab and on the field by the company has resulted in world-leading recoveries. The Ema project has some of the best, if not the best, recoveries for any ionic clay rare earth project inside Brazil and perhaps anywhere in the world (Fig. 5).

World class recoveries averaging 69% NdPr and 48% DyTb from a bulk sample analysed at ANSTO confirm that Ema rare earth project has some of the highest ever recorded recoveries from an ionic clay rare earth deposit.

Based on these results, the Company has been evaluating the possibility of in-situ leaching of the mineralisation. Field water percolation testing as well as laboratory bench scale diffusion testing using standard, weak magnesium sulphate leaching solution at 0.5M and 0.1M concentration, pH 4.5, at ambient temperatures. The leachability response of the rare earths confirms rare earths are present in ionic form and leachable at low operating cost. Downstream production to a final product, a mixed rare earth carbonate (MREC), has been produced at 99% purity and the high magnetic REO element proportion of 27 – 31% of the basket, positioning it as one of Brazil’s most enriched MREO deposits.