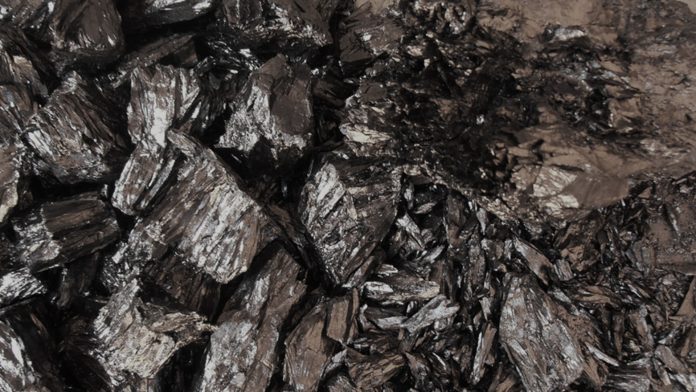

Applied Graphite Technologies (AGT.V) is leveraging high-quality vein graphite from the Queens Mine Complex in Sri Lanka, aiming to meet the anticipated demand for electric vehicles and contribute to sustainable energy solutions.

Applied Graphite Technologies is a Canadian public company listed on the TSX Venture Exchange. AGT is determined to revive the graphite industry in Sri Lanka and become a significant contributor to the energy revolution currently underway. The world’s highest-quality vein graphite is exclusively sourced from Sri Lanka. AGT’s mission is to uncover and harness the untapped potential of AGT’s Queens Mine Complex. Located amongst the best geology in Sri Lanka, in the historic high-grade natural vein graphite deposits.

With one of the most experienced teams in the industry, AGT is committed to innovation, sustainability, and responsible mining practices. We aim to be at the forefront of supplying high-quality vein graphite to meet the enormous growth demands of the lithium-ion battery industry worldwide with an enviable ESG standard.

Sri Lanka has a rich history of mining and exporting graphite, reaching 35,000 metric tonnes in annual production. The natural vein graphite mined in Sri Lanka stands out for its remarkably high grade of + 95% Cg, high degree of crystallinity, and strong electrical and thermal conductivity, making it suitable for various commercial uses.

The emerging trend towards global electromobility presents fresh opportunities to revive Sri Lanka’s graphite industry. AGT employs modern geophysics to define, in three dimensions, the many graphite veins located within the Queens Mine Complex. The graphite veins tend to be vertical and go to depth.

Graphite in lithium-ion batteries: Opportunities for Sri Lanka

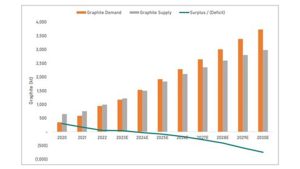

Graphite makes up 95% of the anode material in lithium-ion batteries, with demand for batteries alone reaching three and a half million tonnes by 2030. Stationary Storage Batteries, the size of shipping containers, will eclipse the demand for graphite from electric vehicle batteries. Each gigawatt hour of battery capacity requires 1,200 tonnes of graphite. Consequently, the U.S. Department of Energy classifies graphite as a critical material.

Projections indicate global demand for electric vehicles will surge to 40 million units by 2030. The demand for lithium-ion batteries for EVs has increased, and securing sustainable and reliable critical raw materials (CRMs) has become a policy priority.

Benchmark Mineral Intelligence from the UK calculates that by 2035, the world will need 79 new mines, at an average size of 56,000 tonnes. The high grade of the Sri Lankan graphite translates into a very low capital expense, as no primary processing is required, saving several hundred million dollars that would be required to build a primary processing plant. This means that AGT can define and develop more mines quickly and at a fraction of the capital expenditures required by other natural graphite mines.

Synthetic graphite has been a primary source of graphite for EV lithium-ion batteries due to its high energy per unit mass. However, due to the pressure of Original Equipment Manufacturers (OEM) to reduce the carbon footprint of EV production, the demand for natural graphite is growing rapidly.

Vein graphite is highly desirable due to its unique crystalline structure. It offers superior energy storage capabilities, conductivity, and stability while maintaining a low carbon footprint.

Sri Lanka’s unique natural vein graphite material has outperformed an Industry-Standard synthetic graphite, with a discharge capacity of 165 mAg/g compared to the Industry Standard of 153mAg/g.

Beijing has restricted graphite exports, disproportionately impacting foreign makers of electric vehicle battery components. China dominates the global EV battery supply chain, including the production of graphite, the single largest component. Graphite companies in China process both the natural material mined domestically and overseas and synthetic forms.

(Source: Macquarie Research, March 2023) –All graphite- natural

and synthetic. Currently, there is insufficient graphite to satisfy

demand

Graphite is a supply-critical material that makes up almost half of the input materials for the lithium-ion battery. Currently, natural anode graphite supply is 100% reliant on China. OEMs are actively sourcing non-Chinese sources of graphite, providing a unique opportunity to mine large quantities of graphite to feed the extremely high demand.

Improved political and business environment

Last month, Sri Lanka elected a new president, Anura Kumara Dissanayake, who officially took office on 23 September. President Dissanayake leads the National People’s Power (NPP) party and has promised to restore public trust in the political system.

President Dissanayake has pledged to revitalise the economy and strengthen anti-corruption measures. He aims to develop the manufacturing, agriculture, and IT sectors while adhering to agreements with the International Monetary Fund (IMF) and mitigating the impact on low-income groups through tax relief measures.

The new government has announced the dissolution of parliament and the implementation of general elections, which are scheduled to take place on 14 November. President Dissanayake aims to form a majority in the general elections to solidify his administration’s foundation. Early indications show that the new President is doing exactly as he campaigned.

Please note, this article will also appear in the 20th edition of our quarterly publication.