TriGen Energy’s decarbonisation solutions are supporting the oil and gas sector to meet the immense demands of the global energy transition.

The global energy transition is a monumental challenge, projected to require an investment of $100-200tn over the next 30-35 years to achieve net zero emissions by 2050. This transition demands not only extensive resources but also innovative approaches to finance and scale groundbreaking technologies such as carbon capture, utilisation, and storage (CCUS), energy conversion, electrification, and power storage.

These advancements must be integrated with IT and artificial intelligence (AI) systems to facilitate global emissions tracking and trading. Furthermore, the transition introduces new interdependencies across economic, industrial, and social systems, necessitating novel regulatory and fiscal policies to ensure acceptance and sustainability.

The oil and gas (O&G) sector, with its significant Scope 3 emissions – comprising approximately 80% of the industry’s total footprint – faces immense pressure to spearhead this transition. O&G companies are perceived to bear a moral obligation to address the emissions issue they contribute to.

TriGen Energy’s integrated decarbonisation solutions

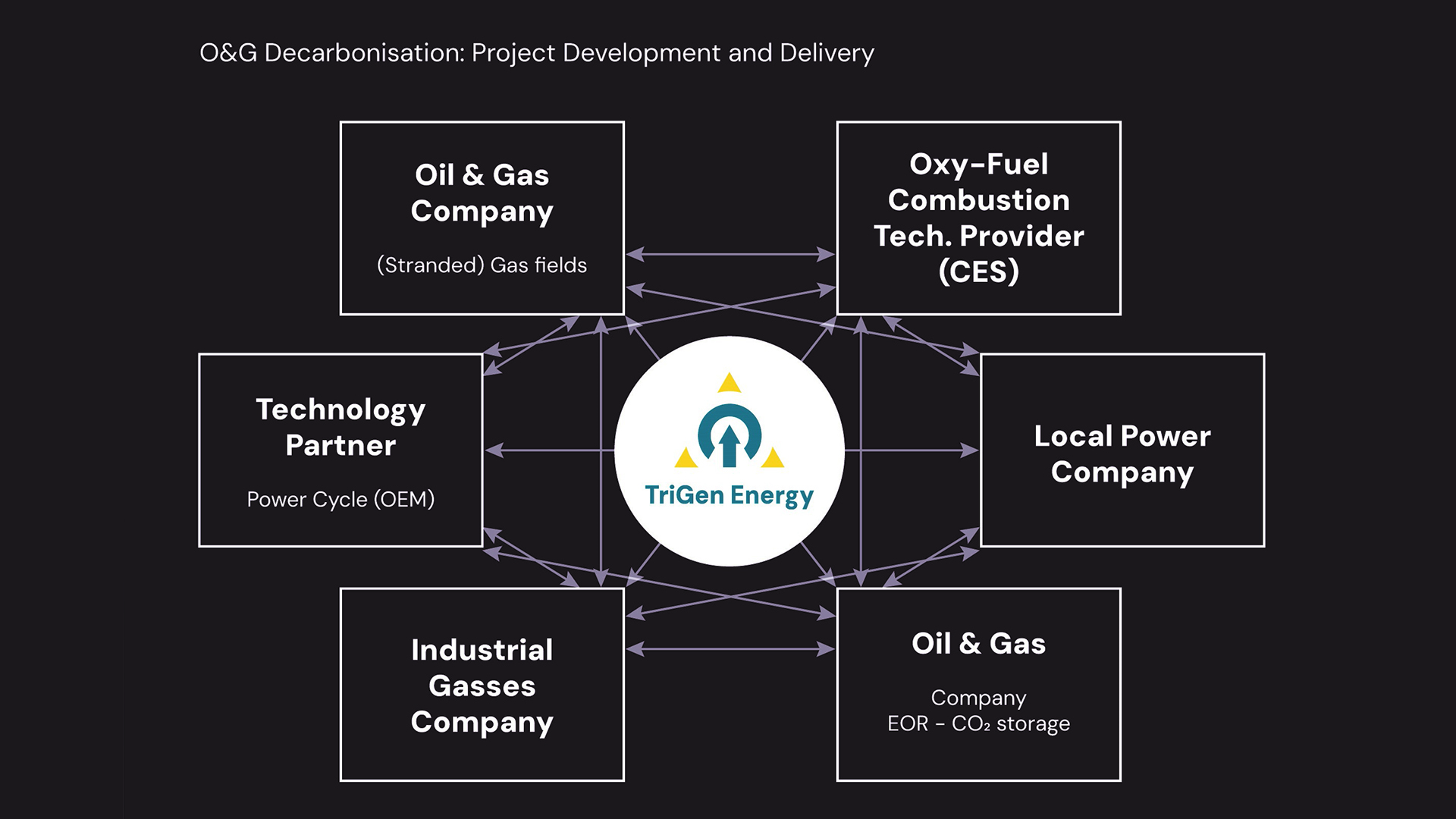

TriGen Energy specialises in crafting comprehensive system solutions that economically capture greenhouse gas emissions. We partner with O&G companies to develop bespoke technical and commercial CCUS strategies that achieve significant emission reductions while remaining profitable. Our preferred technology for achieving substantial Scope 2 and 3 emission reductions is oxy-fuel combustion.

Why oxy-fuel combustion?

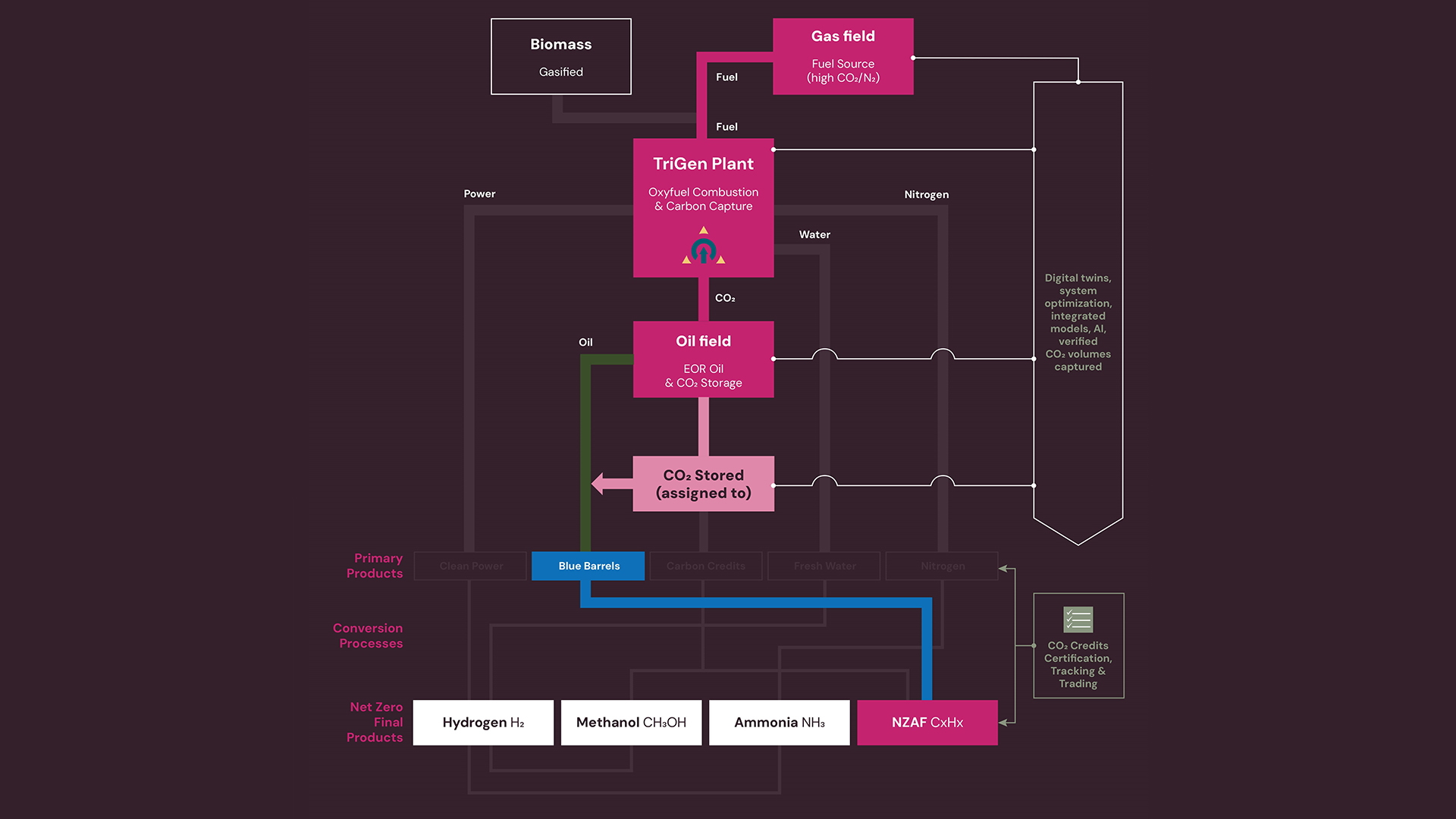

Among the three primary methods for CO2 capture in hydrocarbon-fuelled power systems – pre-combustion, post-combustion, and oxy-fuel – oxy-fuel has traditionally been dismissed due to its high oxygen demand, which can consume 8-10% of a power plant’s output, thereby reducing thermal efficiency. However, TriGen Energy has identified key advantages of oxy-fuel in the context of oilfield decarbonisation, supported by over 20 global engineering studies.

Oxy-fuel combustion systems offer several strategic benefits:

- Reservoir-ready CO2: The process generates CO2suitable for enhanced oil recovery (EOR) and storage.

- Fuel tolerance: It can handle low-quality CO2or nitrogen-contaminated fuels.

- Water production: Instead of consuming water, oxy-fuel plants produce boiler-quality fresh water.

- Nitrogen production: These systems generate significant volumes of nitrogen, which can be repurposed for industrial and O&G applications.

Systems-level benefits

The combined outputs of an oxy-fuel plant – power, CO2, fresh water, and nitrogen – create added value when evaluated at a systems level, particularly in the O&G sector. This integrated approach offsets the lower plant efficiency. TriGen’s solution involves coupling a fuel source (often a gas field) with a TriGen facility to produce dispatchable power, managing CO2/water separation and pumping, and facilitating CO2 storage or use in EOR. This results in ‘clean’ power generation, which commands a premium price or generates sellable carbon credits.

Working with TriGen Energy

TriGen Energy is committed to supporting the oil and gas industry in its decarbonisation journey. We invite O&G companies to collaborate with us in identifying and implementing decarbonisation opportunities within their field portfolios. Our deep expertise in oil and gas, oxy-fuel technology, power and EOR/CCUS integration can help transform oil-field emissions challenges into profitable, sustainable solutions.

Please note, this article will also appear in the 20th edition of our quarterly publication.