Becca Kirk, Biogeochemistry Consultant at the Critical Minerals Association (UK), explains how the answer to the UK copper shortage could be in our homes.

Copper (cu) is a versatile metal, abundant in society due to its properties that make it an excellent electronic conductor used in many electronic products.

Copper has been used in electronics, specifically cables, for many years, yielding millions of tons of material into circulation. With difficulties and lack of domestic recycling of these materials, millions of pounds worth of copper is found unused within the average UK household. Recycling alone could not supply enough copper to meet the projected increased demand, however synonymous recirculation of recycled copper alongside mining could prevent copper shortage in the UK and ensure material is available to meet the increased demand expectations.

This article will dive into these lost copper resources, and the value the urban mine could have for recycling efforts within the UK.

Copper and its abundance

Copper is a reddish metal, prevalent in the natural environment. There are over 150 known copper minerals, and it is a trace element essential to many living organisms, humans included.¹ There are currently around ten copper minerals of economic importance, with around half of the world’s copper currently mined from chalcopyrite (CuFeS2).² Copper is generally unreactive, but its chemical properties make it one of the most useful metals for electrical applications.

Copper in the UK household

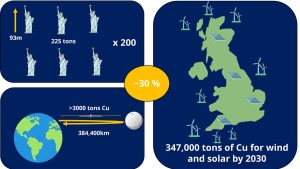

Copper is an abundant material in the average household. It is present in the home wiring, white goods, small electronics and household cables. It is a highly recyclable material that can be passed through many production chains before any loss of functionality occurs. Copper is not currently considered critical in the UK; it is a strategic critical material in the EU and listed as critical in the US. Its projected demand is anticipated to skyrocket, and the development of a sophisticated recycling chain for portable copper-based products and cables may provide the UK with a stake in the copper market and provide materials for the manufacture of products for the green energy transition. In unused cables and electricals, the UK has huge volumes of recyclable copper. This equates to approximately 39,000 tonnes of copper, which is enough to build more than 1,200 Statues of Liberty³ and enough copper to nearly replace all the necessity for refined copper for two years.

The electrical function of copper

Copper has been fundamental in the electrical industry since the early 19th century, where its development for telegraphy spiralled into widespread use,⁴ due to the material’s high conductivity and low resistivity. The resulting product was a highly functional material that successfully transmits electrical currents with low risk of overheating.

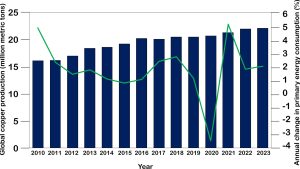

Products containing copper and copper wire have been central in the electrical revolution, only increasing with increased global energy consumption. Except for 2020, global energy consumption has increased by around 0.5-6% yearly for decades.⁵ With that, global copper mining and production has steadily increased to a production of around 22 million metric tonnes in 2023⁶ (Fig. 1). Demand for copper is projected to more than double by 2050 due to renewable technologies such as wind farms, solar PV, heat pumps and electric vehicles requiring high volumes of electrical components. It is believed there could be a 6.5-million-ton gap in production and demand for copper by 2033.⁷

Is copper critical?

Due to the increased demand, the European Union named copper a ‘strategic critical mineral’ in 2023⁷ and the U.S Department of Energy listed it as a ‘critical mineral’.⁸ A strategic critical mineral is defined as a mineral with diplomatic or defence importance, and ‘critical minerals’ as minerals necessary for the industrial objectives of a country or company often with supply chain vulnerabilities.⁹ Currently, the UK does not define copper as a critical mineral.

Copper production and consumption in the UK

Historically, copper has been mined in vast quantities in the UK, with around half the 19th century global output coming from Cornwall. However, British ores no longer contribute to global production. Even still, the UK’s consumption of refined copper remains around 22,000 metric tons annually, despite increasing scrap recycling capabilities over time.10

Copper is one of the most recyclable metals, with the ability to pass through many recycling streams without losing functionality and efficiency. The UK currently has no established recycling chain for copper despite being a significant consumer, and electrical product user. The UK exports between 200,000 and 500,000 tons of scrap copper yearly for recycling,11 and it is believed around 30% of copper in use is now from recycled sources. It is predicted that at least 40% of mined copper is still in circulation.

The household copper mine

Recycling of copper has been ongoing for many years alongside the production of new copper-containing products and refining of copper ore. Global copper production from 2010-2023 alone equated to around 300 million tons. Therefore, vast quantities of copper currently aren’t entering recycling streams. Outside of the 40% still in use, and 30% of recycled material,12 there is a huge volume of copper missing from these streams. A large volume of copper is sitting in the average household, many of this functional in household wiring and white goods. However, new research states that there are around 1.3 billion unused electrical items stored in the UK household or mismanaged in waste streams, and around 630 million unused copper cables.³

The copper content of the household cable

Generally, all high-quality electrical cables are copper or aluminium based. Cables that transfer power and information contain copper wiring, and lower quality wires sometimes contain aluminium in addition to copper. It is an industrial standard for copper wires to be high quality, and it is a requirement for wires to contain 99.1% minimum pure copper.13 This is generally to minimise overheating risk and maximise the function of the electrical product.

The composition of the electrical cable varies depending on function. This affects the number of wires, their gauge (thickness), length and amount of cladding needed for them. For many UK electricals, cables are manufactured to account for the need of the ground, earth and neutral wire for the three-prong plug system in place. However, the number of ‘cores’ (copper wires within a cable) can vary to values of around 7-20 wires for household cables such as some USB cables, fairy lights and extension leads.

The thickness and gauge of copper wire is standardised using the American Wire Gauge size chart as a general convention,14 and these gauges correlate to the function of the cable the wires are manufactured into. As a rule, the thickness directly relates to the amount of electricity the cables are transferring and a greater thickness makes a higher output, more robust cable set. Therefore, when regarding copper content, it can be said that not all cables are created equally. In terms of copper weight per metre of wire, this can vary from 0.3g to 50g based on the function of the cable. However, factors such as heat output relating to the use of heavy-duty electricals require greater volumes of cladding and insulation for the cables. This increases the overall weight of the cable further alongside the greater masses of copper for these cable types. When considering all factors, it can be estimated that the average proportion of copper in a cable is around 20% to 40% of the total mass of the wire. Factoring this into the 630m unused copper wires estimated in the UK, over 3,000 tons of copper is currently unused and wasted in UK households and waste streams.³

The implications of the forgotten electrical drawer

The growing gap in copper caused by the loss of materials, unused in UK households, has been exacerbated by the lack of publication and knowledge of recycling routes for these materials. While suppliers have been responsible for the return of electrical goods for many years, copper cables have not been included in these rules and recycling campaigns have often been poorly publicised and not widely known.

Local policy has not always been the most beneficial in the return, reuse and recycle of products containing copper and other metals. However, in recent years, consultations for change have created more sustainable routes for reliable feedstock of recycled metal products. If we laid the UK’s unused cable out, it could be long enough to travel to the moon and back and carry over 3,000 tons of copper. This alone could fulfil the UK’s yearly technological demand for copper and provide 30% of the 347,000 tons of copper needed for the UK’s planned solar and wind energy projects from now to 2030.³ Therefore, it is clear, where the UK copper mining industry has declined, the opportunity for a stake in exportable and re-extractable scrap copper has skyrocketed. With better management of waste streams, and encouragement to clear out the dreaded cable drawers, the UK could contribute more than £200m of copper³ from recycling these products alone, and significantly reduce supply and demand risks for years to come.

Conclusions

An average UK household holds a significant volume of copper in unused cables and portable electronic materials that could help provide the UK with a stake in the copper recycling and production market. Encouraging the population to recycle their unused electricals to specialist recycling centres to enter circular supply chains will provide a reliable feedstock for the long-term recycling industry within the UK. Furthermore, a greater understanding of the composition of copper cables and materials allow for streamlined recycling routes and the reduction of unnecessary loss of materials as currently exhibited with the products.

Pairing this with the contribution of finance into a UK recycling stream through government and private investment would allow the UK to begin to develop a recycling industry for copper within the country and allow the country to directly benefit from the material through profit and use. Investment would be further encouraged through the addition of copper to the UK Critical Minerals list, highlighting the necessity of the material for both national security and green energy technologies.

References

- Lossin, A. (2001), Copper. Ullmann’s Encyclopaedia of Industrial Chemistry. Available at: http://onlinelibrary.wiley.com/doi/10.1002/14356007.a07_471/abstract

- BGS (2007), Commodity profile copper, Available at: https://nora.nerc.ac.uk/id/eprint/7977/1/OR09041.pdf

- Future of Copper Consumption Report from Material Focus, featuring Bloomberg Intelligence and Royal Society of Chemistry, September 2024.

- Blake-Coleman, Barrie Charles (1981). The Rise Of Copper Wire, Its Manufacture And Use To 1900: A Case Of Industrial Circumspection.

- U.S. Energy Information Administration (2023); Energy Institute – Statistical Review of World Energy (2024)

- USGS Mineral Commodities Survey, Copper, 2024. Available at: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-copper.pdf

- European Commission, Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs, Grohol, M., Veeh, C. (2023) Study on the critical raw materials for the EU 2023: final report.

- U.S. Department of Energy, Critical Materials Assessment 2023

- Critical Minerals Association, Defining Criticality – What Makes a Critical Mineral?, 2021. Available at: https://www.criticalmineral.org/post/defining-criticality-what-makes-a-critical-mineral

- Jaganmohan, M. Approximate unwrought copper consumption volume in the United Kingdom (UK) from 2009 to 2022. Available at: https://www.statista.com/statistics/470246/copper-consumption-in-the-united-kingdom-uk/

- International Trade Centre. (2020). Annual volume of copper waste and scrap exported by the United Kingdom (UK) from 2010 to 2019 (in metric tons). Statista. Available at: https://www.statista.com/statistics/516013/uk-quantity-of-export-of-copper-waste-and-scrap/

- International Copper Association, Circular Copper: Building a Culture of Sustainability, 2021. Available at: https://internationalcopper.org/resource/circular-copper-building-a-culture-of-sustainability/

- Stratton, S.W. Department of Commerce and Labor, Circular Bureau of Standards, Copper Wire Table, 1912.

- ASTM B258-14. Standard Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical Conductors, 2014. Available at: https://web.archive.org/web/20140722072347/http://www.astm.org/Standards/B258.html

Please note, this article will also appear in the 20th edition of our quarterly publication.