Researchers from ETH Zurich have investigated the use of sustainable building materials to provide better passive dehumidification of indoor spaces.

Rather than being released into the environment by a mechanical ventilation system, the moisture is temporarily stored in the sustainable building materials and later released when the room is ventilated.

The researchers studied the effects of hygroscopic materials, which helped high humidity be absorbed by walls and ceilings and temporarily stored there.

“Our solution is suitable for high-traffic spaces for which the ventilation systems already in place are insufficient,” explained Guillaume Habert, Professor for Sustainable Construction, who supervised the ETH research project.

Sustainable building materials from marble quarrying

The team followed the principle of the circular economy in their search for suitable hygroscopic materials. The starting point is finely ground waste from marble quarries.

A binder is needed to turn this powder into moisture-binding wall and ceiling components. This task is performed by a geopolymer, a class of materials consisting of metakaolin (known from porcelain production) and an alkaline solution (potassium silicate and water).

The alkaline solution activates the metakaolin and provides a geopolymer binder that binds the marble powder to form solid, sustainable building materials. The geopolymer binder is comparable to cement but emits less CO2 during its production.

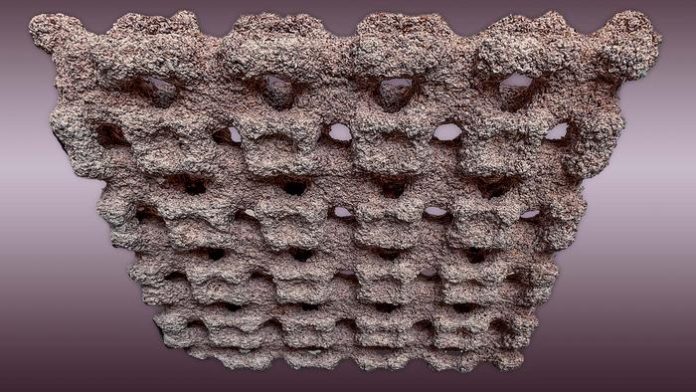

The researchers succeeded in producing a prototype of a wall and ceiling component measuring 20 × 20 cm and 4 cm thick. Production was done using 3D printing in a group led by Benjamin Dillenburger, Professor of Digital Building Technologies.

In this process, the marble powder is applied in layers and glued by the geopolymer binder (binder jet printing technology).

“This process enables the efficient production of sustainable components in a wide variety of shapes,” Dillenburger stated.

Moisture-controlling components increase comfort

Combining geopolymer and 3D printing to produce a moisture reservoir is an innovative approach to producing sustainable building materials.

Building physicist Magda Posani led the study of the material’s hygroscopic properties at ETH Zurich. The project is based on the doctoral theses of materials scientist Vera Voney, supervised by Senior Research Associate Coralie Brumaud and architect Pietro Odaglia, who developed the material and the 3D printing machine at ETH.

Posani said: “We were able to demonstrate with numerical simulations that the sustainable building materials can significantly reduce humidity in heavily used indoor spaces.”

For the simulation, it was assumed that the walls and ceiling of a reading room used by 15 people in a public library in Oporto, Portugal, had been completely lined with hygroscopic components.

Posani calculated how often and to what extent the humidity exceeded the comfort zone, such as 40-60% relative humidity in this virtual reading room over the course of a year.

From this, she calculated a discomfort index, a figure that expresses the loss of comfort caused by excessively high or low humidity. If the reading room were fitted with moisture-binding components, the discomfort index could be reduced by 75% compared to a conventional painted wall. If components were used that were 5cm thick instead of just 4cm, the discomfort index fell by as much as 85%.

A climate-friendly alternative to ventilation systems

The hygroscopic wall and ceiling components are climate-friendly as they cause significantly lower greenhouse gas emissions over a 30-year life cycle than a ventilation system that dehumidifies air quality to the same extent.

In the simulation calculations, the wall and ceiling components were also compared with clay plaster, which has been used since time immemorial and passively regulates air humidity in indoor spaces.

This old technique proved to be even more climate-friendly than the hygroscopic materials. However, the plaster has a lower storage capacity for water vapour.

The research shows that the combination of geopolymer and 3D printing can be used to produce wall and ceiling components for efficient moisture buffering.

Due to this proof of concept, the technology is ready to be further developed and scaled for industrial manufacture.