The European Commission has approved a monumental €48m state aid package to propel France into the forefront of electric vehicle (EV) innovation.

This financial boost will help Envision AESC France establish a cutting-edge battery plant in Douai, Hauts-de-France.

The initiative is set to drive job creation, regional economic development, and accelerate Europe’s transition towards a sustainable future.

Battery factory to boost regional jobs and sustainability

France is taking decisive action to strengthen its EV infrastructure by supporting the first phase of a battery plant capable of producing 9 GWh annually.

This direct grant will fuel the construction and launch of the state-of-the-art facility, creating around 1,000 direct jobs and even more indirect employment opportunities.

Strategically positioned in Hauts-de-France, the plant is designed to be fully carbon-neutral, reinforcing the EU’s commitment to sustainability and industrial growth in developing regions.

Renault and Envision’s partnership

The new battery plant emerges as a cornerstone of a strategic alliance between French automaker Renault and Chinese powerhouse Envision.

This joint venture will establish a large-scale production hub in Douai, adjacent to Renault’s Georges Besse factory.

The facility will manufacture high-performance lithium-ion batteries, specifically designed for Renault’s next-generation electric models.

Initially, the plant will deliver 9 GWh of battery capacity per year. However, its full potential extends far beyond this, with the possibility of expansion to 30 GWh by 2030, depending on market demand.

This could lead to the addition of multiple production units, reinforcing France’s position as a leading player in Europe’s EV battery sector.

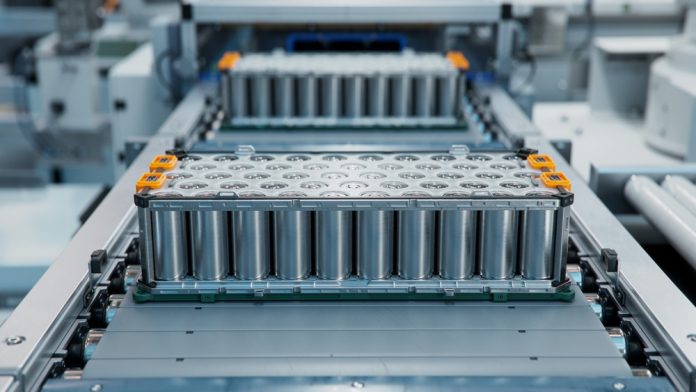

Next-generation battery production

The battery plant will incorporate three advanced production stages:

- Electrode manufacturing: Transforming essential raw materials like lithium oxide, nickel, manganese, and cobalt into high-performance battery components.

- Cell production: Precisely assembling battery cells through electrode compression, electrolyte injection, and structural formation.

- Module assembly: Integrating battery cells into durable casings for use in EVs, electric trucks, and stationary energy storage solutions.

Beyond automotive applications, the facility’s production capabilities may also support renewable energy initiatives, enabling efficient wind and solar power storage.

Why Europe must ramp up EV battery production

The expansion of battery plant production across Europe is vital to reducing dependency on foreign suppliers, particularly from Asia.

With the EV market growing exponentially, ensuring a localised battery supply chain is critical for meeting stringent EU sustainability targets and securing long-term energy stability.

Key benefits of domestic battery manufacturing include:

- Strengthening energy security: Reducing reliance on external sources while stabilising costs.

- Driving economic growth: Generating high-value jobs and reinforcing Europe’s industrial base.

- Advancing sustainability: Aligning battery production with the EU’s ambitious carbon neutrality goals.

The Envision AESC France project in Douai represents a crucial step in achieving these objectives, ensuring Europe remains at the cutting edge of clean energy technology.

The approval of this landmark €48m investment underscores Europe’s commitment to a greener and more self-reliant future.

As EV adoption surges, projects like the Douai battery plant will be instrumental in shaping the landscape of sustainable transportation.

With scalable production capabilities and strategic expansion plans, France is poised to become a leading hub in the European EV battery supply chain.