The ARENHA project is working to overcome the technical challenges of using green ammonia for flexible, safe, and profitable energy storage.

Renewable energy is playing an important role in addressing some of the key challenges facing today’s global society, such as climate change, energy costs, and energy security. However, renewable energy deployment requires higher energy storage capacity to overcome the inherent intermittency of renewable resources and increase their share of generation capacity and integration to the grid. The main issue is matching energy generation to demand.

Different energy storage technologies are available, such as batteries or pumped hydro. However, they cannot solve all issues of energy storage because of their constraints. Moreover, geological factors often affect their deployment. Battery systems could be decisive components of the energy management system, especially for fast response services and short-term grid storage.

Why ammonia?

The Power-to-X technologies (Power-to-Gas, Power-to-Chemicals, Power-to-Liquids) that turn renewable energy into energy carriers – that can be later used – could be a suitable solution for different energy storage needs. In this conversion, the X can refer to a wide number of possible energy carriers, including fuel, gas, heat, hydrogen, chemicals, ammonia, and liquids.

The only sufficiently flexible mechanism allowing large quantities of energy to be stored over long time periods at any location is chemical energy storage via hydrogen or carbon-neutral derivatives.

Hydrogen is considered as an ideal and clean energy carrier because its combustion produces only water as a by-product. Therefore, hydrogen produced from electrolysis could be a key pathway to unlocking the full potential of renewable and seasonal energy storage of large energy quantities and, more specifically, for all situations dealing with a large energy-to-power ratio situation. Hydrogen has a low volumetric energy density, which requires it to be either compressed to high pressure, liquefied, or combined with other elements acting as hydrogen carriers.

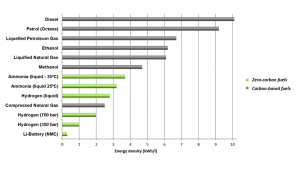

When comparing the volumetric energy density of different fuels (Fig. 1), ammonia is a carbon-free and dispatchable energy carrier allowing it to store large quantities of renewable electricity. It is a primary candidate to allow a secure and clean supply of renewable energy for various stationary or mobile applications and can provide a wide range of energy storage services using existing infrastructures, well-defined regulations, and acceptable safety history for over 75 years.

Existing ammonia production plants produce around 3,000-6,000 tonnes of NH3 per day, but this well-known process currently involves H2 production from natural gas reforming. Ammonia can be liquified by compression to ten atmospheres at room temperature, or by cooling down to -33°C atmospheric pressure. However, to store hydrogen at scale it needs to be compressed to around 350-700 times atmospheric pressure, or cryogenically cooled to around -253°C. Therefore, the storage and transport of ammonia is easier, less energy-intensive, and more cost-effective than storing and transporting hydrogen.

However, technical challenges must be overcome to ensure the flexible and cost-competitive production of ammonia from intermittent renewable electricity sources. In addition, efficient energy discharge processes from NH3 must be developed to leverage the clean energy produced upstream by the renewable asset.

The ARENHA project

The ARENHA H2020 project is a European project with global impact, seeking to develop, integrate, and demonstrate key material solutions enabling the use of ammonia for flexible, safe, and profitable energy storage.

Ammonia is an excellent energy carrier due to its high energy density, carbon-free composition, industrial knowhow, and relative ease of storage. ARENHA will demonstrate the feasibility of ammonia as a dispatchable form of large-scale energy storage, enabling the integration of renewable electricity in Europe and creating global green energy corridors for Europe’s energy import diversification.

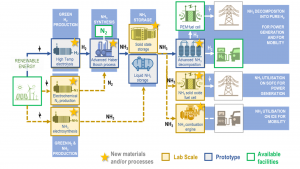

The ARENHA project aims to use ammonia as a green hydrogen carrier, and for this purpose, it develops its main activities around the full power-to-ammonia-to-usage value chain, addressing green hydrogen production, ammonia synthesis, ammonia storage, and ammonia dehydrogenation (Fig. 2).

Innovative materials are developed and integrated into groundbreaking systems to demonstrate a flexible and profitable power-to-ammonia value chain and several key energy storage and discharge processes. Two different levels of research and development are addressed within the frame of ARENHA.

The first is basic research for developing long-term future technologies, such as direct electrochemical ammonia synthesis from nitrogen and water and electrochemical nitrogen synthesis. The other is basic research and small prototypes for developing short- to medium-term technologies of the ammonia value chain.

Specifically, ARENHA is developing advanced solid oxide electrolysis cells (SOECs) for renewable hydrogen production, catalysts for low temperature/pressure ammonia synthesis, solid absorbents for ammonia synthesis intensification and storage, catalysts, and membrane reactors for ammonia decomposition for pure hydrogen (>99.99%) production.

Energy discharge processes studied in ARENHA tackle various applications from ammonia decomposition into pure H2, direct ammonia utilisation on SOECs for power, and ICEs for mobility.

ARENHA will demonstrate the full power-to-ammonia-to-usage value chain at TRL 5 and the outstanding potential of green ammonia to address the issue of large-scale energy storage through life cycle assessments, sociological surveys, and techno-economic analysis deeply connected with multiscale modelling. For this purpose, breakthrough technologies will be developed and integrated along the overall value chain. The main technical objectives on the material and system levels are:

- To develop and integrate innovative solid oxide cell materials into a flexible, high-temperature electrolysis demonstration unit, producing 1.5 Nm3/hr of hydrogen at ambient pressure to be connected to a real photovoltaic plant;

- To develop and integrate innovative materials into a synthesis loop, enabling the operation of a flexible Haber-Bosch production unit of 10 kgNH3/day at lower pressures (≤80 bar) and temperatures(<450°C);

- To develop and integrate innovative materials into a decomposition reactor able to generate 10 Nm3/hr of pure hydrogen (>99.99%) from green ammonia;

- To develop and test innovative materials and solutions for the alternative direct synthesis and utilisation of next-generation green ammonia;

- To demonstrate ammonia as a flexible energy carrier through the development of a fully integrated prototype for green ammonia synthesis and decomposition; and

- To assess the social acceptance, techno-economic-environmental feasibility, and replication potential of the developed value chains.

The ARENHA consortium is composed of 11 partners from seven countries (The Netherlands, Denmark, Germany, Estonia, France, the UK, and Spain). Each partner has been selected due to its excellence in its specific industrial or research field to form a new ammonia supply chain from European resources, including:

- Energy and Transport key players: ENGIE, who is the number one independent power producer globally and PSA ID, part of Stellantis, Europe’s second-largest vehicle manufacturer;

- Three hi-tech SMEs: ELCOGEN, Proton Ventures (PV), and HYDROGEN 2 SITE (H2SITE), which are focused on innovative solutions for hydrogen generation through solid oxide cells, decentralised ammonia production, and membrane reactors for hydrogen production and purification, respectively;

- Five top European research centres (TECNALIA, FhG-IKTS, DTU, STFC, and TUE), who all have a strong record of research and innovation in the field of materials, reactors, and process design; and

- Other key organisations such as CNH2, which has extensive expertise in the hydrogen value chain.

Scheduled work for the project comprises activities related to the whole energy storage value chain. It is focused on using ammonia as a green hydrogen carrier and develops its main activities around green hydrogen production, ammonia synthesis, ammonia storage, ammonia dehydrogenation, and direct ammonia utilisation.

The novel materials and systems will be integrated into a testing infrastructure combined with an ammonia storage tank for proof of concept and validation to demonstrate the full power-to-ammonia-to-usage value chain at TRL 5.

ARENHA’s impact on the energy storage industry

Today, European energy and transport systems are mainly based on fossil fuel carriers. This leads to major concerns regarding energy supply security, climate change, air pollution, and increasing energy service prices.

In a well-established strategy, Europe aims to supply more than 80% of electricity from renewable energy sources by 2050, a large part being harvested from offshore. However, the integration of renewable energy in power systems requires the development of large-scale energy storage.

Long-term energy storage under a dispatchable form as ammonia is key to providing Europe with the necessary tools to nurture its energy independence. It will provide flexibility to the power system, secure the safe integration of renewables, and explore the vast untapped Indigenous renewable potential, for instance, from offshore. It also has the potential to diversify Europe’s energy import corridor through multiple partnerships with new exporting third parties (long-distance transportation of renewable energy through ammonia).

In addition to promoting the integration of renewables in the grid and decreasing the energy import dependency by diversifying the energy supply, green ammonia can be used directly as a zero-carbon fuel (e.g. in industrial burners, gas turbines, and internal combustion engines). For instance, the maritime sector is considering green ammonia, together with methanol and hydrogen, as alternative fuels for decarbonising the energy sector.

Ammonia can be also used to generate electricity using fuel cells, gas turbines, or internal combustion engines, as well as act as an energy carrier for the provision of hydrogen for different applications (e.g. hydrogen fuel cell vehicles and power generation). This could allow for the electrification and decarbonisation of many industrial sectors. Several initiatives are already ongoing worldwide to develop and use green ammonia for energy storage.

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 862482.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 862482.

Disclosure: The present document reflects only the author’s views, and the European Commission is not responsible for any use that may be made of the information it contains.

Please note, this article will also appear in the thirteenth edition of our quarterly publication.