EIRES researchers Ana Sobota and Fernanda Neira D’Angelo discuss their projects to convert carbon dioxide and use it to build important chemical compounds.

In an attempt to reduce the amount of CO2 in the air, scientists all over the world are looking for possibilities to convert the waste molecule into feedstock.

EIRES researchers Ana Sobota and Fernanda Neira D’Angelo have several projects that facilitate CO2 conversion and use it to build useful chemical compounds.

“Converting carbon dioxide is far from easy. It is a fully oxidised molecule, which has no heat value or functionality whatsoever. It is what we call a low-value molecule, meaning that you need to introduce a lot of energy to be able to do anything useful with it. Therefore, one of the biggest challenges in CO2 conversion is to develop environmentally advantageous and economically competitive technologies,” said chemical engineer Fernanda Neira D’Angelo, who co-ordinates the TU/e’s reactor design efforts in the four-year European project C2FUEL.

Using non-thermal plasmas to break down the CO2 molecule

One of the options under consideration is to use so-called non-thermal plasmas to break down the CO2 molecule, explained physicist Ana Sobota.

The term non-thermal plasma refers to an electrically charged state of matter where the heavy ions are at room temperature, and the electrons contain a lot of energy.

Through collisions with these ‘hot’ electrons, the CO2 molecules start to vibrate. When the vibration is strong enough, the bonds between the individual atoms making up the molecule will break.

“To split CO2 in a single step requires a lot of energy. With a plasma, instead of hitting it with a hammer, you poke it a little bit, but over and over again. The molecule accumulates the energy from all of the pokes until eventually it breaks.”

The PIONEER project studies three topics: the fundamentals and mechanisms of CO2 plasmas, advanced catalysis for CO2 activation, and innovative routes for plasma catalyst interaction.

Sobota’s PhD student Harry Philpott focuses on the interaction between the plasma and the catalyst.

“One of the challenges is that conventional chemistry does not use electric fields, while in plasmas, electric fields are exceptionally high. So the first thing we need to know is how high these fields are exactly as the plasma comes into contact with the surface of the catalyst.”

The aim is to develop economically and environmentally viable CO2 conversion technologies

Plasma catalysis is a rather new field, Sobota explained.

“That means that everyone is working at the edge of their discipline, trying to answer fundamental questions like What happens when a plasma meets a catalyst? What reaction rates can we expect under plasma conditions? What is the optimal combination between plasma, catalyst and reactor type?”

Over the past decade, Sobota has been working on methods to measure the interaction between plasmas and a variety of materials.

“What once started with rather simple perfect dielectrics, now culminated in this project in studying catalysts, which are very complex molecules. I am very happy that we were able to develop a method to actually measure these electric fields at the relevant interfaces.”

Where the PIONEER project focuses on the fundamentals, the C2FUEL project Neira D’Angelo is engaged in has a slightly different focus.

“C2FUEL is led by ENGIE, a French energy company dedicated to the energy transition,” she explained.

The aim is to develop energy-efficient, economically and environmentally viable CO2 conversion technologies which are to be demonstrated at Dunkirk between a DK6 combined cycle power plant, the Arcelor Mittal steel factory, and one of the major European harbors.

The idea is to selectively remove the carbon dioxide present in the blast furnace flue gas and combine it with green hydrogen generated by electrolysis fed with renewable electricity to produce two promising energy carriers.

“The aim of the C2FUEL project is to produce both formic acid and dimethyl ether,” Neira D’Angelo explained.

Dimethyl ether is already known as an alternative diesel-like fuel for trucks and ships. Formic acid is a promising substance to carry hydrogen, which can be used as a fuel as well.

Now, the focus is on scaling up the production of dimethyl ether.

A challenge: The chemical reaction is thermodynamically limited

In terms of reactor design, which is the part of the project TU/e is responsible for, one of the biggest challenges is that the chemical reaction is thermodynamically limited.

“During the reaction a lot of water is produced, which deactivates the catalyst and limits the conversion. Therefore, we had to come up with solutions to remove the water from the reaction,” Neira D’Angelo said.

That is easier said than done, the chemical engineer explained: “For this specific application, a membrane reactor is the most suitable candidate. However, if you use an ordinary membrane, chances are that hydrogen will also go through.”

Eventually, together with project partner Tecnalia, TU/e researchers developed a stable membrane that is selective for water only.

“We have tested our membranes first at lab scale to see what would be the optimal composition, how to produce them at a larger scale, and how their performance is affected by different reaction cycles. Project partner Tecnalia has then produced the membranes at the required scales.’”

Though the true proof of the pudding will be in the eating, Neira D’Angelo is confident that the final reactor will do what it is supposed to do.

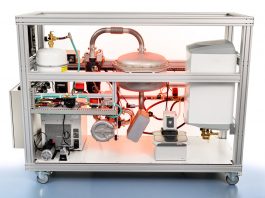

“Currently we are building a scaled up version of our lab-scale reactor in a container, which will be shipped to Dunkirk later this year.”

Solving bottlenecks and sharing know-how

When looking at the energy transition in a broader sense, one of the most uplifting characteristics of the C2FUEL-project is that the CO2 conversion technology that has been developed is not process specific, and thus can also be of use for other applications.

“All in all, I think technology is not the major bottleneck when it comes to using CO2 as a feedstock for fuels. Of course, there are still some technical issues to solve, but we have shown already that this is feasible. The biggest problem is the economic side of things. One of the main tasks I see for us as researchers is to develop solutions with increased performance to drastically reduce costs,” Neira D’Angelo stated.

Sharing knowledge and expertise is key to accelerating developments, both scientists think.

Sobota added: “To me, perhaps the nicest thing coming from the PIONEER project is a database that will be online soon, which provides a comprehensive overview of where we have looked and what we have found. These data are open for scrutiny by other researchers, potential partners, and the scientific and regulatory communities. The aim is to not only help them get an idea of where to look and what to expect with certain set ups, but also what doesn’t work. Since the latter seldomly ends up in publications, I think that is an extremely useful addition to advance the field.”

For more information, please visit:

c2fuel-project.eu

co2pioneer.eu