Agro2Circular is aimed at upcycling waste from the agrifood industry, creating effective enzymatic recycling technology for complex plastic waste and fruit and vegetable waste.

Agro2circular is a European Project funded by the H2020 Research & Innovation EU programme (GA No. 101036838). We aim to develop a territorial circular solution for the upcycling of two types of waste generated by the agrifood industry in the region of Murcia, Spain: multilayer-multi material metallised plastic films and fruit and vegetable waste.

To this end, several DEMOS/Pilot plants have been built by integrating several technologies that will transform waste into valuable products that can be used as secondary raw material by the agrifood industry. In this way, we are closing the loop.

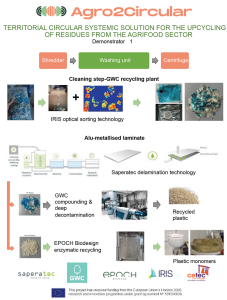

DEMO 1: Upcycling multilayer/multi-material metallised packaging

In Agro2Circular, we have developed a process to provide an upcycling solution to a kind of packaging that is currently sent to landfills. This packaging, called ‘aseptic bag in box’, is made of several layers of plastics and aluminium. A2C’s solution is firstly collecting, cutting, washing and drying the waste in the GWC recycling process, a step that is followed by IRIS novel optical sorting technology able to separate the metallised plastic fraction from the non-metallised plastic fraction.

‘saperatec’ delamination technology can remove the aluminium from the metallised fraction and separate different plastic layers to obtain plastic fractions made of compatibilised materials (PE, PE-PA, PE-EVOH) suitable to be used as secondary raw material by the packaging industry.

The plastic fractions that are not compatible (PE-PET) are subjected to an enzymatic degradation process using novel enzymes developed by EPOCH BIODESIGN. The polymers are degraded into their monomers and oligomers ((terephthalate (TPA) and ethylene glycol (EG), short-chain organic compounds), which are further used as secondary raw materials in bioprocesses (DEMO 2).

DEMO 1 key technologies

The GWC recycling process has been optimised to facilitate the subsequent optical sorting and delamination. The cutting and washing steps were validated according to the needs and performance of IRIS and separate technologies, with an evaluation of the efficiency of washing organic contamination and of the final size of the plastic shredding optimal for effective sorting.

IRIS has listed different possible solutions that could be used in order to distinguish between the metallised and non-metallised fractions. Trials were carried out with three distinct methodologies: a) the use of a NIR-HSI, which is based on the use of a spectroscopic camera to generate hypercubes that can be analysed using chemometrics; b) LIBS, which is an atomic spectroscopy technique which uses a punctual measurement analysis able to identify specific peak related to the presence of aluminium in a given sample, and c) the measurement of change in electromagnetic currents.

Results showed that the NIR-HSI technique can be a good solution for the identification (and further sorting) of the targeted samples. When it comes to sorting, IRIS has worked on adapting the colour and speed of the conveyor to the recycling capacity of the final pilot plant.

The saperatec technology is based on specifically designed separation fluids for the delamination of composite materials. Exemplary composite materials in the application field of packaging include aluminium barrier packaging consisting of polymer layers (typically PE, PP, PA, PET, PVC) and aluminium foil or metallisation.

The separation fluid is water-based and formulated with special additives. The delamination takes place at the interface between the aluminium-layer and the polymer layer. In the first step, adhesive properties are reduced, and in the second step, the layers are mechanically separated. The saperatec process is therefore regarded as an advanced mechanical recycling process.

Epoch Biodesign has focused on the engineering of improved enzymatic activity against the PE/PET waste substrate. The enzyme sequence space is vast and complex, and generating a better enzyme at random would take a very long time. Instead, Epoch has developed a synthetic biology platform that can design and build thousands of enzyme variants and rapidly test them against PE and PET plastics. The best candidates are selected and used to generate new, improved variants to test again. This cycle has been run multiple times since the start of the project, and enzymes of improved activity and stability have been generated.

Starting from a heterogeneous waste stream, CETEC has worked to improve the chemical characteristics of the mixed PE/PET waste to make it more easily attackable by the enzymes. This has involved the experimentation with multiple techniques to reduce crystallinity, reduce the molecular weight and improve surface characteristics, such as polarity.

This combination of physical testing and moderating of plastic waste and advanced enzyme engineering puts us in an advanced position to generate enzymatic recycling technology that manages complex and mixed plastic samples and scales them up to process significant volumes of plastic waste from the food industry.

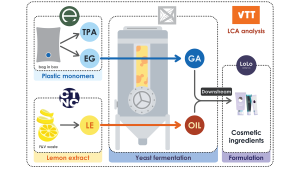

DEMO 2: Microbial biotechnology for the production of building blocks and ingredients for the cosmetic industry

Demonstrator 2 covers the biotransformation of the PET enzymatic degradation products (TPA & EG) and fruit and vegetable waste into valuable and safe products for cosmetic formulations.

Yeast factories to transform ethylene glycol-EG into glycolic acid-GA

While most research focuses on bacterial EG metabolism, the University of Milano-Bicocca (Italy) has demonstrated that yeast is able not only to consume EG but also to produce glycolic acid (GA) as the main by-product. The tested yeasts, unlike bacteria, can efficiently accumulate GA, as they appear naturally incapable of utilising it as carbon and/or energy source. Therefore, they can be considered the most suitable host for this production.

Besides, it has been found that a combination of yeast and process conditions leads to a bioconversion of EG into GA with a yield of over 75%.

Yeast cell factories to transform residual biomasses into microbial oil

Oleaginous yeasts can accumulate microbial oil when grown on fruits and vegetable residual biomass. In order to ensure the sustainability of the oil extraction from the cells, a series of green solvents were tested, and they were demonstrated to perform well when compared to traditional solvents. Microbial oil has the potential to substitute the traditional fossil sources of oil used in cosmetics, such as liquid petroleum, paraffin oil, and white mineral oil. Cosmetics also take advantage of oils extracted from plants, and while in some cases this also sustains a socially relevant business (as in the case of argan oil), in many other cases, it is another source of conflict for land use and resources.

Data for LCA analysis have been collected, which will be of help in evaluating possible industrial implementation of these processes. The obtained products have been tested by Lolo Cosmetics as an end user for moisturising and antioxidant creams.

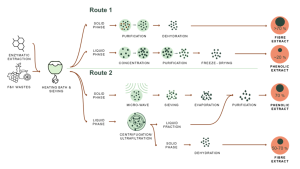

DEMOs 3 and 4: Extraction of valuable substances from fruit and vegetable waste

The industrialisation of natural product extraction processes has gained importance due to its potential to align with the principles of the circular economy and sustainability, especially in the agri-food sector. DEMOS 3 and 4 aims to present the pilot-scale upscaling of extraction routes developed in the Agro2Circular (A2C) project, which focuses on valorising agri-food residues, particularly fruit and vegetable (F&V) waste, to recover bioactive compounds and dietary fibres, as shown in Fig. 3.

The processes described here highlights how green technologies such as enzymatic (Route 1), as well as microwave-assisted extraction (MAE) (Route 2), have been optimised for industrial application.

The process begins with the collection, transport and pre-treatment of F&V waste, following a Waste Management Plan to guarantee the safety and innocuousness of the raw material.

Overview of technologies and scale-up

The pilot-scale extractions following these routes were based on prior laboratory studies. Two main technologies were explored: Route 1 (developed by CTNC and CITROMIL) employed enzymatic and ultrasound-assisted extractions (the latter has been discarded since the results obtained were similar to those achieved with enzymatic extraction, and the latter is more efficient in terms of energy consumption and equipment investment), while Route 2 (developed by SSICA and DOMCA) focused on the combination of enzymatic pretreatment with microwave-assisted extraction.

Each method offers unique advantages in the recovery of bioactive compounds, including polyphenols, and in extracting high-quality dietary fibres from organic residues like lemon, artichoke, broccoli, apple, and/or grape.

For Route 1, the enzymatic extraction method (EAE) utilised the enzyme cellulase to break down agri-food waste and release bioactive compounds like dietary fibres and phenolic compounds. The process has shown success in scaling up, with operational parameters such as solid-liquid ratios and enzyme dosages optimised.

In Route 2, microwave-assisted extraction (MAE) was used after enzymatic pretreatment to further enhance the yield of phenolic compounds extraction. Microwaves create intracellular pressure that breaks plant cell walls, facilitating faster extraction compared to traditional methods. Hydroalcoholic solutions were used as solvents, aligning with the green chemistry principles of the project.

Filtration, purification and stabilisation steps were integrated into the extraction process in both routes to ensure the purity and preservation of the extracts.

Results from pilot scale-up

The upscaling of these technologies was achieved with capacity metrics exceeding those typically seen at the laboratory level.

For example, Route 1 scaled up extraction to a throughput of 200 L/h, while Route 2 achieved microwave-assisted extractions in 120 L batches In Route 1, EAE was particularly efficient, producing

high yields of dietary fibre, obtaining extracts with purities of up to 75% (in dry matter) from artichoke residues, or phenolic extracts with purities of almost 20-23% (in dry matter) from artichoke and grape wastes, respectively.

Similarly, the MAE method in Route 2 demonstrated enhanced polyphenol extraction efficiency, achieving concentrations above 70%, making the extracts suitable for nutraceutical, cosmetic, and food formulations.

Stabilisation stages, however, presented challenges, particularly related to the high energy demands of freeze-drying and vacuum distillation. The reports suggest that stabilisation can become a bottleneck in the production process.

Environmental and economic viability

Sustainability assessments, including Life Cycle Assessment (LCA) and Life Cycle Costing (LCC), were embedded in the scaling process to ensure the industrial feasibility of these extraction technologies. These analyses revealed that while energy-intensive processes like freeze-drying contribute significantly to the environmental footprint, the overall processes are designed to minimise waste and solvent use.

These demonstrators also highlight the adaptability of the technologies for different matrices, allowing their replication in various regions of Europe, which have different F&V wastes of interest to revalorise.

Another critical challenge identified was water usage, particularly in the fibre purification stage. Strategies such as reducing the dosage of oxidising agents and implementing water recycling in the purification process helped optimise water consumption. The findings indicate that further improvements in water management and energy efficiency will be essential for the economic success of these valorisation technologies.

Industrial relevance and circular economy potential

The upscaled extraction processes described in this publication hold considerable promise for the valorisation of organic residues from the agri-food industry. By recovering valuable bioactive compounds and fibres from waste, these processes support

circular economy principles, reducing the need for synthetic chemicals and promoting the use of renewable natural resources. Additionally, the flexibility of the extraction routes makes them adaptable for different types of waste, from lemon and artichoke to grape residues.

The project also emphasises the potential market applications of the extracts obtained, with formulations targeted for the food, nutraceutical, and cosmetic industries. The adaptability of the processes for different waste sources and the potential to tailor the technology for specific market needs enhance the scalability and commercial viability of the processes.

In conclusion, the pilot-scale industrialisation of green extraction technologies, as developed in the A2C project, presents a viable pathway for the circular economy in the agri-food sector. Further research and innovation are necessary to optimise energy and water use, but the foundation laid by this project demonstrates the potential for large-scale adoption of these sustainable technologies.

DEMO 5: Production of PHBV and carotenoids from fruit and vegetable waste

Owing to the combined properties of biodegradability, biocompatibility, and thermoplasticity, polyhydroxyalkanoates (PHAs) are identified as promising naturally occurring polyesters for bio-based plastics production. PHAs are a class of aliphatic polyesters that are synthesised by many species of microorganisms as carbon and energy storage reservoirs, usually under nutrient-limiting conditions. Few organisms can produce PHBV when fed with simple sugars alone, and one such organism is Haloferax mediterranei, an extreme halophile with a versatile metabolism, enabling PHBV synthesis from a broad range of substrates.

Producing biodegradable plastic PHBV from waste

CETBIO has developed a Haloferax mediterranei cell factory for PHBV and carotenoids production using organic waste fractions from the agrifood processing industry. The process has been optimised at a 300L scale, feeding the microorganisms with lemon waste and apple waste as the sole carbon source. WETSUS and the University of Alicante (Spain) have worked on a process to extract the PHBV and carotenoids using sustainable chlorine-free solvents. The obtained PHBV has been formulated and tested by end users from the plastic processing industry.

DEMO 10: DIS (Data Integration System) – technological tool for efficient waste management

Effective waste management is a growing concern across the European Union (EU), particularly in industries dealing with plastics and organic wastes, where most of their end-of-life is for disposal. As part of its efforts to promote sustainability, the European Commission has introduced initiatives to promote circularity and ensure traceability throughout the entire lifecycle of waste, from generation to recycling and manufacturing or formulation of its new use.

The Agro2Circular Data Integration System solution has been specifically designed for the waste management of plastics and organic wastes and their treatments, aligned with the EU’s legislative requirements and driving its transition towards a circular economy.

This DEMO has been developed in collaboration with CETEC, defining the traceability in the value chains. EVRYTHNG is implementing the blockchain technology, Equmetrics is developing the technology for data acquisition and EXUS is developing technologies for Big Data and predictive tools.

The role of traceability in waste management

Traceability is defined by ISO (International Standardization Organization) as the property of the result of a measurement or the value of a standard where it can be related to specified references, usually national or international standards, through a continuous chain of comparisons, all with specific uncertainties.

In this scope, the Agro2Circular Traceability Tool has been designed to help the industry identify materials, origin, processes, quality and traceability. It integrates the value chain of multilayer plastic materials and organic products in their transformation by companies in a continuous flow, drawing and creating traceability in real time, securing and guaranteeing all information with Blockchain technology, to comply with the European standard UNE 15343:2008 on traceability of plastic recycling and evaluation of conformity and recycled content.

When it comes to traceability, it is important to differentiate between internal and external traceability. The first refers to the traceability required for the internal management of a company, while external traceability refers to the capacity to trace a batch all along its lifecycle inside a value chain. This traceability is differentiated if it is generated from the final product to the original waste, backwards traceability, or forward if the needed information originates in the waste.

Predictions for efficient waste management LCA

Another key factor in efficient waste management is the capacity of the system to find the best alternatives when it comes to the environmental, economic, and social dimensions.

The Data Integration System (DIS) incorporates an Evaluation and Decision Tool that uses Machine Learning to analyse the most optimal routes for a determined waste. Due to the nature of the technology, it needs to gather previous data from each one of the processes to be able to generate precise predictions on decisions to make.

Digital product passport for product identification and environmental impact

DIS also aims to improve waste management and recycling using a Digital Product Passport (DPP) approach. The DPP is a system that assigns digital identities to products, enabling the tracking of their lifecycle and key information like composition and sustainability claims, improving transparency and facilitating efficient recycling. Our implementation uses QR codes, digital twins, and blockchain technology to help manufacturers, recyclers, and consumers access vital information on product composition, usage, and end-of-life handling, ensuring proper recycling processes and reducing waste.

The system also aims to combat greenwashing by providing verifiable sustainability claims through digital records backed by a blockchain. By embedding data directly into products, the technology allows for more precise sorting of plastic waste, boosting recycling rates and efficiency. This increased transparency addresses a significant problem in recycling, where non-recyclable materials often end up in recycling streams, reducing the quality of recycled products. The use of blockchain technology, a decentralised ledger, ensures the data remains secure and tamper-proof, increasing trust across the supply chain and the stakeholders.

Disclaimer

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 101036838

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 101036838

Please note, this article will also appear in the 20th edition of our quarterly publication.