Advanced Magnet Lab, Inc. (AML), an esteemed leader in groundbreaking magnet technologies, has celebrated a year of remarkable progress.

The company has made significant strides in advancing its technology, enhancing capabilities, and nurturing strategic relationships, all in pursuit of establishing itself as a key player in the commercial manufacturing of permanent magnets.

Revolutionising manufacturing with PM-Wire™

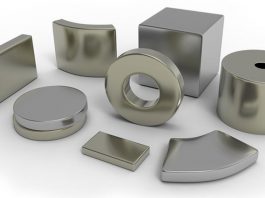

Central to AML’s manufacturing prowess lies its cutting-edge technology, PM-Wire™. This scalable and modular manufacturing process stands out for its ability to produce both non-sintered and sintered permanent magnets at a high rate and yield.

The adaptability of this process to various applications, particularly those benefiting from unique magnet configurations and material compositions like electric motors, sets a new benchmark in the industry.

The first steps and collaborative ventures

AML’s initial foray into high-rate commercial manufacturing will focus on non-sintered permanent magnets tailored for specific commercial and defence clientele.

Collaborative efforts, notably with Oak Ridge National Laboratory (ORNL), are underway to enable electric motor applications.

The partnership aims to innovate and co-locate manufacturing facilities with customers or supply chain partners, with discussions initiated across several US jurisdictions for potential site locations.

Redefining efficiency

The collaboration with ORNL stands as a testament to the game-changing potential of PM-Wire™.

By replacing a complex array of 2,750 sintered magnets with just eight non-sintered helical magnets, AML’s technology not only streamlines manufacturing but also eliminates the need for active cooling in the motor rotor while maintaining equal motor performance.

This innovation holds promise, potentially propelling AML into the realm of commercial automotive applications.

Diversified applications and future endeavours

Beyond automotive advancements, AML is actively engaged in multiple programmes with commercial entities.

These initiatives aim to provide similar transformative benefits across various industrial sectors, including industrial generators, aerospace, and defence.

Looking ahead, AML remains committed to expanding its development initiatives. Exploring new material compositions for both sintered and non-sintered permanent magnets, the company’s two facilities in Brevard County, Florida, spanning approximately 10,000 square feet, will continue to serve as hubs for prototyping, research, and development of alloys and magnets.

Scaling manufacturing through partnerships

AML’s vision involves organic scaling of manufacturing in 2024, facilitated by strategic collaborations with customers and material providers.

Presently, the Florida locations can support an output of around 200 metric tons per annum of permanent magnets, demonstrating the company’s commitment to meeting growing demands through innovative approaches.

Advanced Magnet Lab, Inc.’s remarkable strides signify a pivotal shift in the landscape of magnet technology, promising a future marked by efficiency, sustainability, and unparalleled innovation in commercial manufacturing.