StorEn Tech explores the advantages of using vanadium redox flow batteries in telecom applications.

Energy storage systems are becoming a requirement for many electrical power delivery systems. Flow battery technology has commercial advantages over other energy storage systems because of the inherent efficiencies and life cycles available that do not exist with other energy storage technologies.

StorEn is developing a revolutionary suite of products that can: Economically store and supply large amounts of electricity on demand; incorporate long life, low maintenance costs; and is scalable from both a power and storage capacity perspective.

StorEn’s Energy Storage System (ESS), based on a proprietary flow battery design, is particularly beneficial to renewable energy providers, power utilities and industrial end users such as telecom service providers. StorEn’s technology offers these industries the ability to cost effectively ‘inventory’ electricity on a large scale and call to service this electrical energy on demand. Unlike other battery technologies, StorEn’s ESS does not lose capacity after thousands of charge and discharge cycles.

Description of StorEn’s vanadium flow battery system

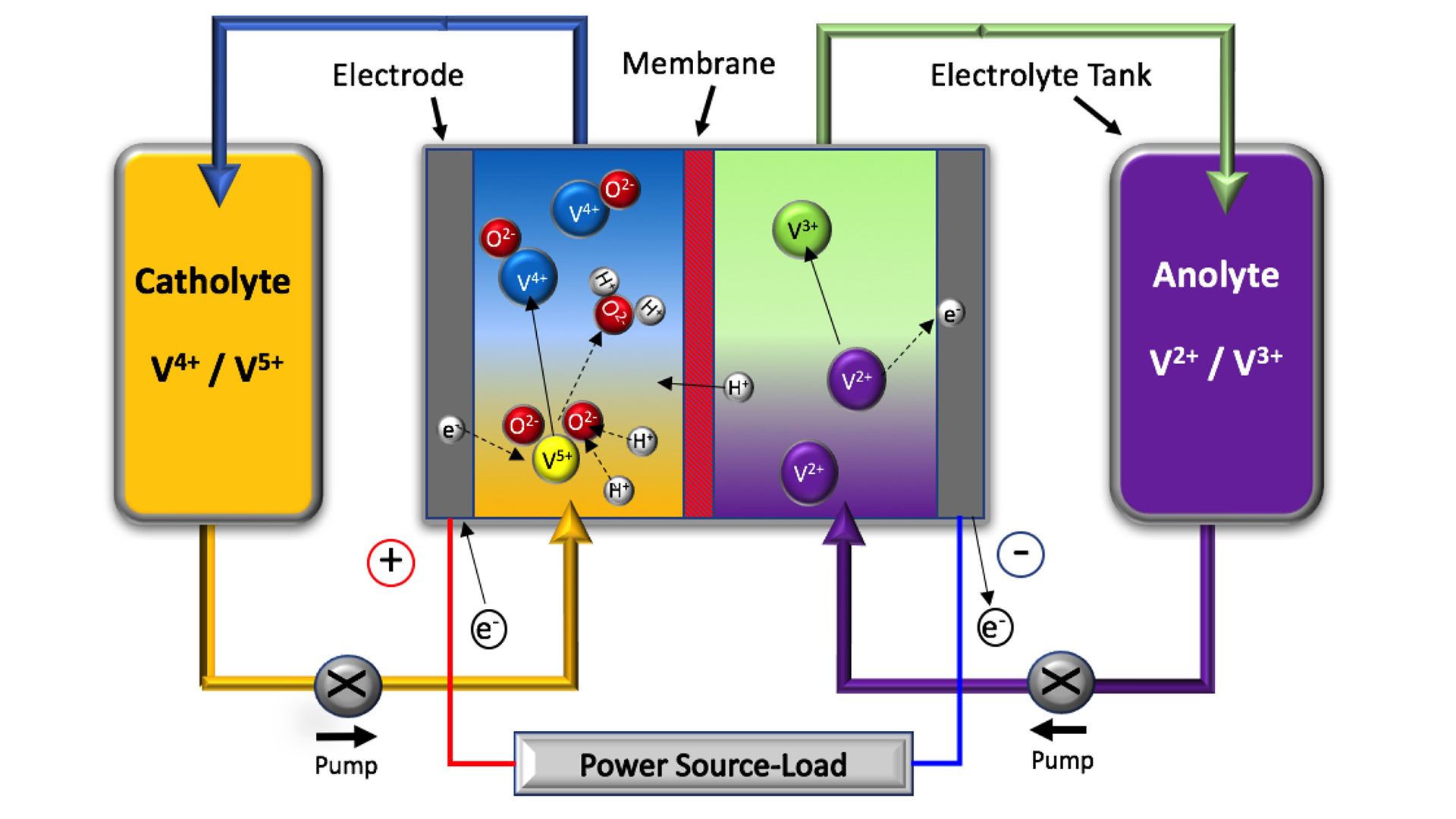

What is a vanadium flow battery? A flow battery is a type of rechargeable battery in which the energy is stored chemically in liquid electrolytes. Unlike conventional batteries that store all of their reactive materials within the cells, a flow battery stores the electrolyte in tanks. The electrolyte is pumped through the cells and the electric energy is generated by a chemical reaction that takes place as the electrolyte passes through the cell stack. The liquid is then returned into the tanks.

There are two electrolytes, one that is positively charged and one that is more negatively charged. The technology exploits the natural ability of vanadium to exist in four different oxidation states. Each electrolyte tank is charged with vanadium in a different redox couple. The two electrolytes do not mix together but are separated in the cell stack by an extremely thin membrane that only allows selected ions to flow through.

Also in the cells are very stable carbon electrodes, manufactured to a proprietary process and formulation, where the transfer of chemical energy to electrical energy takes place. The reactions only involve the change of state of oxidation of the vanadium pentoxide, and the electrodes do not change physically or chemically.

Additionally, the presence of vanadium in both electrolyte tanks does not lead to cross-contamination of the metal species, as it takes place with any other technology using different metals.

Therefore, a large number of charge and discharge cycles, in excess of 20,000 cycles, may be performed without any significant decrease in capacity.

Generally, the cells are grouped together in blocks known as stacks (cell stacks or modules). In each stack the cells are connected electrically in series by bipolar plates, i.e., conducting plates that have positive electrolyte on one side and negative on the other. Therefore, the stack voltage is the sum of the voltage of the individual cells. A ten-cell stack has ten times the voltage of a single cell.

Conventional batteries (or cells) may be grouped in series and are then known as a battery string. The energy of a battery string is limited by the poorest battery (cell). However, each cell of a flow battery is practically identical because they share the same electrolytes. Therefore, flow batteries do not suffer the same intrinsic limitation.

The stack power (in kW) is also the sum of each cell’s power. The power of each cell is governed by the battery chemistry, temperature, and cell dimensions, as well as a few other parameters. However, the energy (in kWh) of the battery is dictated by the amount of electrolyte that is present in the tanks. With more electrolyte (energy) the battery will be able to provide the same amount of power for longer periods of time. There is practically no upper limit to the energy to power ratio of a flow battery.

Flow batteries are unique in being able to independently specify the energy and power to meet the demands of any given application.

Applications that will benefit from StorEn Technology’s flow battery system include the following:

Telecom applications

StorEn targets on-grid, off-grid, and poor grid situations at telecommunications sites in North, Central and South America, Europe, India, Africa, and remote island communities worldwide. For on-grid applications, StorEn’s ESS can be used in a number of applications such as traditional battery backup and, at the same time, shift energy use to a lower time of use rate. In remote locations, StorEn ESS works well at sites that use a ‘hybrid’ and/or cycling approach where a diesel generator is combined with renewable energy such as wind and/or solar to power cellular and microwave sites.

In this market, StorEn’s first to market product offers immediate benefits such as lower life cycle costs, minimal maintenance and longer discharge capabilities with end users experiencing short payback cycles for many systems. The additional environmental benefits include a significant reduction in diesel emissions and minimal disposal concerns.

Telecom applications: Traditional backup power

In the majority of telecommunications systems worldwide, lead/acid batteries are used to provide DC backup functionality or to bridge to a much longer-running backup system such as a diesel generator. In grid connected systems, these batteries serve only as a UPS, only being called into service when the grid fails or there is an outage due to weather. In North America and other locations, the normal specifications for backup battery power are to operate up to four hours continuously on batteries, allowing for continued emergency communications during the outage. In off-grid telecom sites, diesel generators provide the primary source of power and batteries are used as backup if the on-site generator fails to operate.

Lead/acid backup power systems are designed for infrequent use and generally for shallow depths of discharge due to the fact that the life span of lead/acid batteries are controlled by the number of discharge cycles and the depth of discharge during these cycles. Battery life is also controlled by operating temperatures and by the charging voltages used during the charge cycle. Recharge times are often five times that of the discharge cycle, thus making lead/acid batteries very inefficient to operate in high cyclic locations. Four hours of discharge can take up to 20 hours to recharge.

For lead/acid batteries, the depth of discharge plays an important role in determining the operational life of a battery. If an acceptable depth of discharge is exceeded, the battery system’s life is severely depleted. A maximum of 30% depth of discharge is considered acceptable for most telecom designed lead/acid battery systems. StorEn’s flow battery technology eliminates these issues. The StorEn flow battery has the ability to cycle between charge and discharge virtually an unlimited number of times with no ill effect on the battery. The StorEn-ESS also allows for complete discharge every time, again, with no ill effect. The third feature is the StorEn flow battery technology has the ability to rapidly charge and approaches a one-to-one charge/discharge ratio allowing for quick and rapid response to multiple power outage scenarios. In locations such as India, Africa, Central and South America, telecom sites experience multiple outages each day, stressing the capacities of backup power systems and requiring continuous replacement of lead/acid battery systems.

StorEn will be addressing the backup power market for telecommunications on a worldwide basis. Although telecom service providers have a number of choices for backup power systems, the value of replacing lead/acid batteries with StorEn flow battery technology will enhance a telecom service provider’s network by increasing reliability, improving longevity of the backup power system and dramatically improving performance by allowing rapid charge cycling.

Telecom applications: Off-grid prime power and on-grid poor power sites

Telephone service providers are constantly studying ways to curb the costs of operating remote telecommunications transmission sites. The more remote the site, the higher the costs of energy used to power the site, regardless of whether the energy is utility power or other sources – such as on-site, diesel-powered generators. Remote transmission sites are also expensive to service and support. Many sites are accessible only by helicopter or during the summer months.

There are tens of thousands of transmission sites across the globe, many of which rely on localised generation of electrical power from on-site diesel generators. Attempts have been made to augment the diesel generators with some form of energy storage, such as large banks of lead/acid batteries. Battery banks have traditionally been used as backup power systems, operating only when the main source of power is not available.

Attempts have been made to augment the diesel generators with some form of energy storage, such as large banks of lead/acid batteries. Battery banks have traditionally been used as backup power systems operating only when the main source of power is not available.

There have been attempts to use traditional batteries for cycling down generators during extended periods of time. In theory, using batteries could save fuel costs or help eliminate generator noise and pollution at sites located close to populated areas. Traditional battery technologies such as lead/acid and lithium batteries cannot hold up to this aggressive charge and discharge cycling. The cost to constantly replace damaged batteries becomes more expensive than the realised operational costs of using batteries in this capacity.

Worldwide, telecommunications service providers have relied on diesel generators as a primary source of electrical power at remote telecom sites where utility power is unavailable. Diesel generators provide primary power to microwave transmission stations located on top of mountains or on remote islands. The value of the transmitted information easily justifies the high costs of localised diesel power generation. These sites are typically referred to as ‘prime power’ sites.

Microwave transmission is used as the backbone of many telecommunication networks. Microwave systems have proven a reliable and inexpensive medium to transmit voice and data communications over long distances or rough terrain such as mountain ranges, between islands, or locations where cable access is not feasible.

For prime-powered microwave sites, the fuel cost tops the list of operating expenses. Other expenses, such as engine service and maintenance, are directly related to engine run hours, load, and temperature. Generally, the lower the load – as a percentage of engine rating – the lower the efficiency of the diesel engine, thus the higher the maintenance costs due to premature engine wear, carbon build-up, and increased oil change schedules.

Microwave transmission equipment is usually a light load for a diesel generator. To increase engine efficiency, a ‘dummy load’ in the form of a resistor bank is added. The energy absorbed by the resistor bank is completely wasted in the form of heat.

Operational cost savings could be realised if it were possible to store the excess electrical energy and turn off the generators for a significant period of time each day. Traditional lead/acid batteries have been used in an attempt to capture the excess energy from the generator, turn the generator off and run completely from the batteries thus turning the site into a ‘cycling power’ site. Unfortunately, there are issues with this solution.

Traditional lead/acid batteries and lithium batteries are limited to the number of deep discharge cycles before permanent damage occurs. An innovative energy storage technology is needed that is not affected by daily deep discharge cycling and can be quickly charged.

StorEn’s flow battery technology is the forerunning solution for this application as traditional battery systems fail to perform well when implemented in off grid sites. StorEn plans to dominate this application by offering tremendous value to telecom service providers who operate equipment off-grid. The amount of fuel savings alone justifies deploying StorEn Flow Battery technology on a large scale.

On-grid energy shifting and UPS backup using the same platform at telecom sites

Typically, every telecommunications site will have some form of backup power system. Power is usually supplied by banks of lead/acid batteries that supply uninterrupted power to the telecommunications equipment during utility power outages. Most telecommunications systems operate on DC voltage and use rectification equipment to convert the AC voltage supplied by the utility into either 48- or 24-volt DC. Larger sites, such as central office sites, or Point of Presence (POP) sites also have permanently installed petroleum generators. The typical load of a central office site is 10-50KW. Backup batteries are typically housed inside a building and are climate controlled as required. Backup batteries are typically replaced on a three-to-five-year cycle based on the number of times they were called into service. There would be many banks of batteries capable of supplying up to 50KW of power for up to two hours of runtime.

The StorEn ESS flow battery system could be a direct replacement for any lead/acid battery bank used in this capacity. Unlike lead acid batteries, the StorEn ESS system has the capacity to be fully discharged and recharged many thousands of times with no detrimental effect on the battery system. The installation of the StorEn ESS system would improve the reliability of the telecom network by lengthening the operational runtime of the backup power system as well as reducing the replacement and disposal costs for lead acid batteries. The StorEn ESS would also decrease the amount of time the system would need to recover from an extended outage as the StorEn ESS charges much more quickly than lead acid batteries.

The StorEn flow battery system can also be used to shift on-peak utility energy demands to off peak periods on a daily basis. By controlling the power rectifiers, power delivered to the telecom transmission equipment can be supplied by the StorEn ESS during peak load times and the battery can be recharged during off peak times. This extended use of the StorEn ESS has no detrimental effect on the battery system thus allowing the telecom service provider to continue to use the battery in the traditional mode as a backup power device. The StorEn ESS would be designed to supply up to six hours of peak load shifting power and an additional two hours of backup energy power for a total of eight hours of energy storage capacity.

Telecommunications cell sites, central office sites, and larger POP (Point of Presence) sites are configured to operate uninterrupted in the event of voltage dips and power outages. The load curves of many such sites exhibit flat profiles with occasional demand spikes due to air conditioner inrush currents.

Based on the Time-of-Use (TOU) tariffs in place in many states in the US, StorEn’s flow battery technology could be used to shift the load from the grid to the batteries during the hours of the day when the utility company is experiencing peak demand. However, at the same time, the primary purpose of these batteries, namely, to provide a UPS function, would not be compromised. Conventional and advanced batteries cannot have the power and storage duration sized separately from one another. Flow batteries, however, allow for the independent specification of power and energy. This feature allows the telecom service provider to specify the amount of power to be delivered by the battery and, independently, specify the length of run time used for backup and for the peak shaving application.

The key here is the flow battery serves two important roles: It replaces and improves reliability over existing lead/acid backup batteries used to bridge an outage until the on-site genset starts, and it reduces utility costs by shifting the utility energy costs from prime time to night-time tariff rates.

Our vanadium flow battery technology leads the way in Green House Gas Emissions (GHGs) Emission Reduction and sustainability.

One StorEn Energy Module 5kW/30kWh coupled to a photovoltaic system, cycling once per day at 100% Depth of Discharge, would spare the following GHG emissions:

• 7.7 metric tons of CO2 per annum, or

• 154 metric tons of CO2 over the lifecycle of 25 years¹

All StorEn Energy Modules are fully recyclable and deliver environmental advantages when compared to alternative energy storage technologies such as:

• All major components are made of fully recyclable plastic and metals with a recyclability factor close to 100%;

• Disassembling is very easy as all parts are simply bolted together;

• The processing is cost-effective for the majority of parts being primary mechanical reprocessing such as the process used for domestic appliances;

• The only two components requiring specialist treatments are the printed circuit board of the battery management system, that are processed in facilities used for electronic waste such as computers’ motherboards;

• The electrolyte can be processed and reused, or if desired, 100% of the vanadium can be extracted and reused for other applications with no impact on primary mining;

• Lack of toxic metals such as lead, cadmium, zinc, and nickel, which could contaminate the environment;

• Acidity levels are much lesser than lead acid batteries which again could be a hazard; and

• In its lifespan, one StorEn VFB avoids the disposal, processing, or landfill of eighty lead-acid batteries of forty lithium-ion batteries.

References

- Calculator: www.epa.org

Please note, this article will also appear in the seventeenth edition of our quarterly publication.