Professor Michael Goodsite, Director of the University of Adelaide’s Institute for Mineral and Energy Resources – Modern Energy Systems (IMER), highlights the major initiatives that the institute is presently working on to best ensure sustainable modern energy systems and the minerals needed for them.

The importance of the energy sector’s transformation in relation to planetary sustainability cannot be overstated. Clean energy, and its associated technologies, holds the key to reaching globally agreed goals of net zero emissions by decarbonising utilities, transport, heavy industry, agriculture and mining, and achieving the United Nations Sustainable Development Goals (UN SDG).

The work of IMER

The University of Adelaide set up the Institute for Mineral and Energy Resources (IMER) – Modern Energy Systems to drive industry-led, collaborative, interdisciplinary innovation for a positive impact. Most grand challenges require co-operation between multiple fields of expertise, many of whom have not historically worked together.

IMER, guided by an industry advisory board, facilitates this by developing programmes and teams that transcend disciplinary or organisational boundaries to work collaboratively with industry and government on opportunities critical to sustainability, productivity, and global competitiveness for the energy and resources sectors.

IMER’s depth of expertise is aggregated in nine Research Centres under its portfolios: the Centre for Energy Technology (CET); the Mawson Geo Centre (MGC); the Andy Thomas Centre for Space Resources (ATCSR); the Centre for Materials in Energy and Catalysis (CMEC); the Centre for Radiation Research, Education and Innovation (CRREI); the Integrated Mining Consortium; the Australian Research Council (ARC) Training Centre (TC) for Integrated Operations for Complex Resources (IOCR); the Australian Critical Minerals Research Centre (ACMRC) and the Centre for Global Food and Resources (GFAR).

Our combined future – indeed the future of the world as we know it – depends on transforming to a low-carbon approach. IMER uses the phrase ‘Modern Energy Systems’ as its tagline to encompass the infrastructure and strategic know-how required for decarbonisation and the transition to a net-zero emissions energy future, including the key areas of energy storage, hydrogen, and critical minerals.

IMER exists due to support from the University, the State Government, the Australian Government, and industry partners operating in the minerals and mining and energy resources sectors.

IMER’s current projects

IMER’s current significant efforts are focused on Cooperative Research Centres (CRCs), which provide funding for medium to long-term, industry-led research collaborations for up to ten years. CRCs help improve the competitiveness, productivity, and sustainability of Australian industries.

IMER has recently supported the successful bid for the Heavy Industry Low-carbon Transition CRC (HILT CRC). On 30 June 2021, funding for the HILT CRC was formally announced by the Minister for Industry, Science and Technology of Australia. The Commonwealth awarded funding of $39m over ten years, matched by strong support from industry, government and university partners, who pledged contributions totalling $175m cash and in-kind support. “Heavy industry, which produces materials vital to the national and global economy such as steel, aluminium and cement, is responsible for around 30% of global carbon emissions,” says the University of Adelaide’s Professor Gus Nathan, Director of CET and Deputy Director of IMER, who led the successful bid for the HILT CRC and is now also its Research Director. New partners are welcome and encouraged to reach out to the CRC.

IMER research teams are also involved in the Future Fuels CRC and the Future Batteries Industry CRC, where we lead the national mine electrification scheme.

Building on the formula for success with the HILT CRC, IMER researchers are pursuing two new CRCs to be submitted this year: the Scaling Green Hydrogen CRC and the Copper for Tomorrow CRC.

The Scaling Green Hydrogen CRC, with Professor Christian Doonan as Research Director, Paul Hodgson as Interim CEO, and Professor Caroline McMillen as Interim Bid Chair, aims to become the largest single initiative in Australia’s history focused on supporting the scaling up of the emerging Australian green hydrogen sector. It will provide much-needed resources, capabilities, linkages, and partners to accelerate and de-risk the developing green hydrogen industry and related projects.

The CRC will answer questions like: What would perhaps as much as 1TW of electrolyser capacity look like in Australia? How do we scale sustainably, maximising local benefits and maintaining social licence?

The focus will be to address key challenges to help drive collaboration across the electricity, water, chemicals, transport, infrastructure and manufacturing sectors. Activities will include:

- Rapidly develop capability and capacity in technology and supply chains to help deliver Australia’s National Hydrogen Strategy;

- Help decarbonise ammonia and methanol, which are made with hydrogen, as they are critical high-value commodities to Australia’s chemical and agricultural industries. Green hydrogen, ammonia, and methanol can decarbonise transport, manufacturing, electricity systems, industrial processes, and gas networks. They can also become a valuable bulk export; and

- Help convert mobility sectors not suited to battery electrification such as shipping, rail, heavy transport, and aviation to hydrogen by addressing challenges in hydrogen storage, fuel cell systems, green fuel production, and enabling infrastructure.

The CRC will also support the development of a service industry, linking partners to best practice projects and potential hydrogen users, and supporting hydrogen equipment manufacturers’ growth.

The CRC is currently accepting partners, and IMER encourages those interested in this CRC Bid to contact bid leadership.

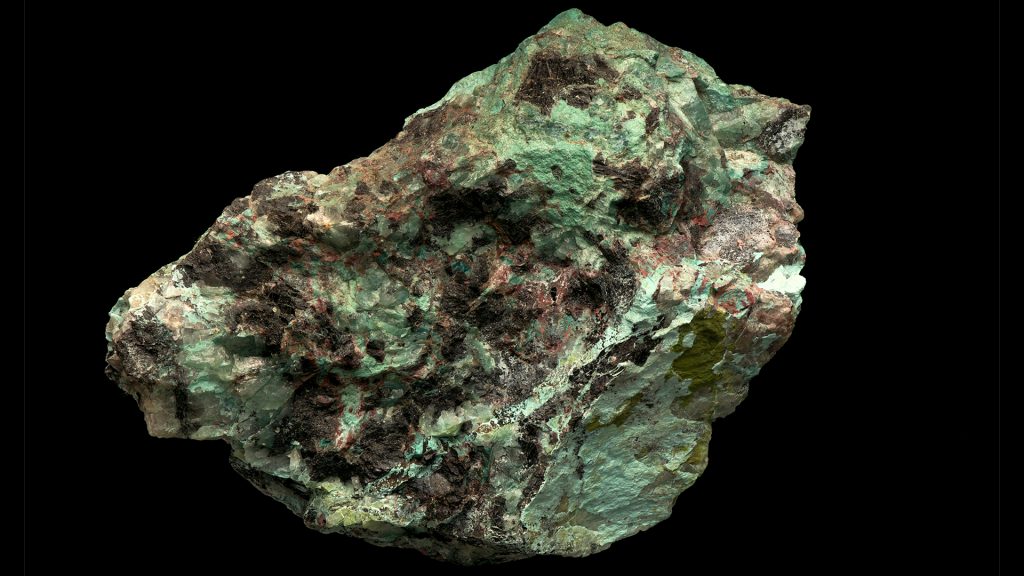

Copper is essential in our transition to a cleaner, greener and more sustainable future

Forecasts predict that from 2025, global power generation will see an inflection point in supply, where coal and gas generation will peak and gradually decline, and solar, and wind will expand. This will also come at a time when mass electrification of transport will accelerate.

For this to happen, the world will need more copper between 2025 and 2045 than has been mined and produced in all of history. To let that statement sink in, we are all going to need a lot of copper!

Following on from this, forecasts also predict that as early as 2023, the demand for copper will exceed supply. And to compound the challenge, copper production is energy and water-intensive, increasing as grades decline, producing ever more emissions and waste products. It will not be possible to meet future demands for copper through merely recycling. Exploring for new deposits is challenging and takes a long time – often over a decade from discovery to production.

It is a sustainable copper paradox: how do we increase the production of copper needed for a green energy society and do so by processing lower grade ores without using more energy and water and producing more waste?

The Copper for Tomorrow CRC, under the research Direction of Professor Volker Hessel, with Gavin Yeates as Interim Bid Chair, will bring together industry and researchers to solve this challenge while helping companies to both hit their environmental, social and corporate governance (ESG) targets and remain profitable. It, too, is seeking partners, and industries interested in joining should immediately reach out to bid leadership.

Australia has a significant role in the raw materials supply chain. According to a media release from the office of the Minister for Resources, Water and Northern Australia, Keith Pitt; “Australia is well placed to be a leading supplier of critical minerals and crucial rare earths elements to help meet growing global demand for minerals used in a variety of modern technologies.”

Australia has the world’s third-largest reserves of copper, is the world’s top producer of lithium, is a large and expanding producer of nickel, has significant upside potential in cobalt, graphite and manganese, and is the second-largest producer of rare earth elements (REEs).

Sustainable mining of critical raw materials and green energy goals

Many of the raw materials mentioned above, like copper, require significant amounts of energy and water to produce and have residues that are currently stored in locations known as tailings storage facilities (TSF), plus what is known as ‘waste rock’ – meaning the rocks are dug out to access the valuable ores.

An example is that in a typical copper, cobalt, or nickel deposit, between 1% and 5% of it is extracted as metal, with the remainder stored in the TSF and waste rock piles. While this residue is treated as waste now, the challenge can indeed be turned into a massive opportunity.

Sustainable mining and processing methods that use cleaner energy and less water are being developed, the waste rock piles have the potential to become construction materials, and the TSFs themselves could be reprocessed to extract much more value.

The fact is that the shift from fossil fuels to battery-electric and fuel cell electric systems has created the demand for materials that we did not require much before. Lithium is, of course, the obvious material, but the increase in demand for nickel, cobalt, graphite, and REEs has been exponential over the last five years or so and shows no signs of slowing down.

Another emerging sustainable mining practice is a method known as in-place recovery. In essence, selectively mining just the mineral, rather than removing and processing the whole rock mass. We have been working with an award-winning company, Environmental Copper Recovery | EnviroCopper, on a so-called CRC Project, helping them achieve sustainable in-situ recovery (ISR) for copper.

It is clear that without innovation, the global mining industry will not meet the demand for copper required of modern energy systems, limiting the pace of sustainable development and constraining the transition to a greener economy. Some solutions to the paradox are emerging, but we need to approach this systematically to achieve the next-level step change. We need to rethink how we make decisions, design mines, and extract and process copper.

So, shifting towards sustainable mining will help address the paradox of meeting increased demand without negative environmental impact.

Applying innovation to meet critical raw material demands while adhering to ESG commitments

The case of lithium-ion batteries (LIBs) is critical because LIBs are relatively new in transport but are rapidly expanding. With more than 2.1 million new electric vehicles (EVs) sold in 2019,1 Bloomberg forecasts that the annual global EV sales will reach 24.4 million by 2030.2 Global battery consumption is set to grow by 25% annually to 2030 alone.

LIBs have a typical lifespan of six to ten years, meaning there is going to be a lot of spent LIBs very soon. This is why IMER is backing another significant initiative at the UoA focused on the ‘Circular economy of Batteries’ – where industry collaboration is both welcome and essential.

From an environmental standpoint, end-of-life LIBs contain cobalt and nickel heavy metals, which can be toxic to our ecosystem. In addition, there are considerable concerns over the safety of stockpiles of end-of-life LIBs due to fire and explosion risks. Hence, it is critical to find solutions to the problem of recycling end of life LIBs.3

Recycling end-of-life LIBs represents an untapped source of valuable materials. It is estimated that the spent LIBs will grow to between 100,000 and 188,000 tonnes in Australia by 2036, and the recoverable value would be between AU$681m and AU$2.5bn.4

IMER and the University of Adelaide have some of the best minds in the world for understanding the most effective ways to reduce impact and extract value from battery materials. Those interested in discussing this with us are welcome to contact Professor David Lewis, the Head of the School where the above efforts are based.

Our way forward

IMER is about collaboration and setting the best team across our institution and partners to address and solve some of society’s greatest challenges. IMER is evolving to the Institute for Sustainability, Energy and Resources (ISER) in April 2022 to emphasise an even greater focus on sustainability. We welcome contact to explore opportunities or to join existing efforts.

Please get in touch with imer@adelaide.edu.au, and our Institute Manager, Dr Chris Matthews, our Senior Administrator, Sarah Keany, or I, will follow up.

References

1 The global electric vehicle market in 2020: statistics & forecasts.

2 We’re Going To Need More Lithium. Bloomberg Businessweek.

4 Lithium battery recycling in Australia: defining the status and identifying opportunities for the development of a new industry: Journal of Cleaner Production, 2019. 215, 1279-1287.

Professor Michael Goodsite Director of the Institute for Mineral and Energy

Resources – Modern Energy Systems (IMER)

University of Adelaide

michael.goodsite@adelaide.edu.au

www.adelaide.edu.au

https://www.linkedin.com/school/uniofadelaide/

https://www.facebook.com/uniofadelaide

https://twitter.com/UniOfAdelaide

Please note, this article will also appear in the ninth edition of our quarterly publication.