To address ESG challenges in a complex environment, battery materials companies need to innovate with increasing agility.

The battery industry is a key driver in achieving climate neutrality goals, particularly by reducing fossil fuel use in transport and supporting the integration of renewable energy sources into the electricity grid through the large-scale deployment of battery energy storage. However, the industry also needs to ensure economical and sustainable battery recycling at the end of its life.

Recycling significantly reduces the environmental impact of the critical minerals used by recovering and reusing them in the production of new battery materials. As is often the case in leading industries, CNGR aims to improve its production processes’ efficiency continually and reduce its carbon footprint. Achieving the highest sustainability standards is a collective effort undertaken by all our talented employees, supported by an ever-growing R&D staff of around 1,000 people, with access to large R&D workshops totalling 15,000 tonnes per year.

Prioritising the supply of sustainable battery materials

At CNGR, sustainability encompasses environmental, social, and governance (ESG) issues: environmental challenges, social responsibility towards our employees, consideration for occupational safety and the surrounding community, as well as responsible corporate governance. CNGR’s Board of Directors has established a sustainability governance structure to ensure that a true culture of sustainability is disseminated throughout the company. The sustainability office also guides and regulates the actions of the group’s businesses, directors, management, and employees in the context of its global activities, as defined in CNGR’s ‘ESG Policy.’ The company also leverages its influence to encourage collaboration with supply chain partners to pursue sustainable development while listening to the voices of its various stakeholders and responding to their key sustainability objectives and needs.

The relentless pursuit of sustainable development by all CNGR employees in recent years has borne fruit, such as CNGR’s Qinzhou industrial base in southern China becoming the first ‘zero-carbon factory’ in the precursor industry, as certified by the world’s leading inspection and certification company SGS in March 2023 (ISO 14064-3:2019). As part of its efforts to reduce its carbon footprint, CNGR has also committed to the ambitious goal of generating 100% of its electricity from clean energy sources by 2025 and achieving carbon neutrality in its operations in China by 2040.

Commitment to sustainability

To effectively support our European customers at a time of rapid market expansion, we are in the process of establishing our first EU industrial base in Finland as a joint venture with the Finnish Mineral Group, a state-owned vehicle with a mission to promote the sustainable development of the Finnish mining and battery industries. CNGR Finland’s industrial operations will integrate state-of-the-art metal refining, nickel-based ternary pCAM production (mostly NMC and NCA precursors) and waste battery recycling. Finland is an attractive business location that supports CNGR’s sustainability objectives, particularly given the access to predominantly CO2-neutral electricity and the Finnish government’s consensus to greatly expand decarbonised electricity production, mainly from wind power, to make Finland the cheapest electricity supplier in Europe. In addition, a nearby desalination plant will provide the water used in the pCAM production process. Also noteworthy is the steam produced in a solid fuel boiler using bio-based fuels such as wood chips or recycled wood and an electric boiler to operate the plant.

Finland also hosts the largest nickel reserves in Europe and, through Terrafame Oy, operates the EU’s largest nickel mine with the lowest carbon footprint of any nickel producer globally. More recently, CNGR also signed a co-operation agreement to establish an additional industrial base in Morocco as a joint venture with the Al Mada Group – one of the largest private investment funds operating on the pan-African scene. This structure will integrate nickel-based ternary precursors, iron- and manganese-based lithium metal phosphate cathodes (LFP and LMFP) and waste battery recycling industrial operations to meet the rapidly growing market demand for high-quality battery materials in Europe and the United States. CNGR and Al Mada share a common vision for the highest sustainability standards in their industrial operations, including using renewable energy. The development of renewable energy is a priority of Morocco’s energy policy. Given the huge potential (solar and wind), the Moroccan government is confident that renewable energy sources will account for 52% of total installed capacity by 2030.

More broadly, we have set specific and measurable targets to continuously create social value and achieve sustainable development based on four pillars: clean energy, resource circulation, health safety, and quality products.

Achieving environmental, social, and governance goals

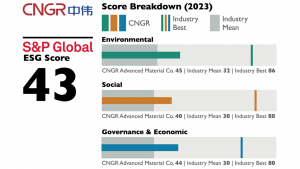

In 2023, CNGR participated in the ESG ratings of three of the main index organisations in the world: the S&P Global CSA Score, the MSCI ESG Rating, and the FTSE Russell ESG Rating. The results reflect the effectiveness of CNGR’s sustainability policy. Specifically, CNGR scored 38 in the 2023 S&P Global CSA Score, an increase of ten points from the previous year, and a score of 43 in the 2023 S&P Global ESG Score. Notably, this corporate sustainability assessment score is a powerful tool for linking a company’s sustainability performance to its business strategy. It also meets the threshold for inclusion in the S&P Global Sustainability Yearbook (China), representing a benchmark level of sustainable development for Chinese companies. At the same time, CNGR’s MSCI ESG Rating has risen from B in 2022 to BB in 2023. CNGR also scored well above the industry average in the FTSE Russell ESG Rating, with a score of 2.6. CNGR is committed to continuously improving its sustainability performance to achieve the highest rating.

As the issue of climate change has become a priority, contributing to the global energy transition away from fossil fuels is at the heart of CNGR’s corporate purpose. CNGR will continue to prioritise and relentlessly focus on sustainability to become the world’s most valuable precursor cathode active materials provider for the battery industry and related advanced services, including recycling. Now more than ever, the world needs innovative companies with a deep focus on sustainability to help mitigate the challenges around us. While contributing to a better life is not only an option, but a must, sustainability and continuous development are integral to the measures we are taking to help build carbon neutrality and strengthen our agility in an increasingly volatile external environment.

About CNGR

CNGR Advanced Material Company was founded in 2014. Now an innovative, fast-growing international company, CNGR is the leading supplier of customised precursor cathode active materials (pCAM) to the burgeoning lithium-ion and, more recently, sodium-ion battery industries. The precursor is a high-tech component in the battery value chain that defines key characteristics of the cathode active material (CAM), such as composition, metal concentration gradient, particle shape, porosity or particle size distribution, with the additional need to control impurities in the ppm to ppb range to provide customers with the highest quality and consistency of product.

CNGR has established a closed-loop industrial chain from raw material smelting and refining, precursor production (pCAM) to recycling of waste batteries as in-house used refined raw materials. An agile company, CNGR is constantly adapting to the needs of its customers and in almost ten years has emerged as a trusted partner of the global battery value chain for an increasing number of the best names in the global battery value chain.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.