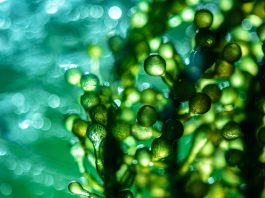

Scientists have conducted four studies that may help to refine the process of manufacturing biofuel from energy cane, potentially ending our dependence on harmful fossil fuels.

The research, conducted at the University of Illinois, has analysed chemical-free pretreatment methods, commercial-scale techno-economic feasibility, and the development of high-throughput phenotyping methods in producing biofuel from energy cane to realise a commercially viable replacement to conventionally used fossil fuels.

The University of Illinois studies are part of the Renewable Oil Generated with Ultra-productive Energycane project (ROGUE), which is an endeavour examining the bioengineering accumulation of triacylglycerides in the stems and leaves of energy cane, which may enhance the production of industrial vegetable oil per acre.

A green future with biofuel

As the world embarks on achieving the green transition, innovating a commercially available, environmentally friendly, and economical replacement for fossil fuels will be crucial to achieving the planet’s net-zero emissions targets. Biofuels are a promising contender for this, as they are renewable, emit less harmful carbon emissions, can be produced worldwide, reduce dependence on foreign oil, and are incredibly efficient. Energy cane is a relatively new crop that has been demonstrated to create several times per acre the biofuel of soybeans; however, obstacles persist in efficiently processing the crops to extract the biofuel.

Vijay Singh, a Founder Professor in the Department of Agricultural and Biological Engineering at the University of Illinois, said: “The productivity of these non-food crops is very high per unit of land. Soybean is the traditional crop used for biodiesel, but we can get a higher yield, more oil, and subsequently more biofuel from lipid-producing energy cane.”

Perfecting the recipe

To fabricate biofuel from crops, the cellulose material of the plant must first be broken down, from which the oil can be extracted in a series of methods.

Deepak Kumar, the co-author of the study and an adjunct research scientist at the Carl R. Woese Institute for Genomic Biology at the University of Illinois, explained: “The first step is to extract the juice. That leaves bagasse, a lignocellulosic material you can process to produce sugars and subsequently ferment to bioethanol.

“One of the critical things in processing any lignocellulosic biomass is a pretreatment step. You need to break the recalcitrant structure of the material so that enzymes can access the cellulose. Because energy cane is a relatively new crop, there are very few studies on the pretreatment and breakdown of this bagasse to produce sugars, and to convert those sugars into biofuels.”

Optimising techniques

An additional obstacle in the pretreatment process is that it yields various undesired compounds that inhibit the enzymes that convert the sugar into biofuel, which inspired the team to investigate the most optimal pretreatment methods that maximise the breakdown while simultaneously mitigating the production of inhibitors. Traditionally, pretreatment processes employ chemicals such as sulphuric acid to break the biomass down at high temperatures and pressure.

“We use a chemical-free method, which makes it more environmentally friendly,” Kumar explains. “Furthermore, harsh chemicals may alter the oil structure or quality in the biomass.”

The team assessed their method by utilising nine different combinations of temperature and time intervals, achieving more than 90% cellulose conversion at the optimal conditions, equivalent to results from chemical pretreatment methods. Their second study advances this research by investigating the relationship between temperature, sugar recovery, and inhibitor production.

Shraddha Maitra, the lead author of the study, said: “We pretreated the lignocellulosic biomass over a range of different temperatures to optimise the condition for minimal inhibitor generation without affecting the sugar recovery. Then we added cryogenic grinding to the process.

“In cryogenic grinding, you treat the bagasse with liquid nitrogen, which makes it very brittle, so upon grinding, the biomass fractures easily to release the sugars. This further increased sugar recovery, mainly xylose, by about 10% compared to other refining processes.”

Comparable strategies are employed in other industries, such as for spices and essential oils, where it is vital in preserving the product’s qualities, although applying them to biofuel production is a novel concept. In their third study, the team used time-domain nuclear magnetic resonance (NMR) technology to analyse the recovery and stability of lipids by observing changes in total, bound, and free lipids after numerous chemical and physical feedstock preprocessing procedures.

The fourth and final study from the researchers studied the commercial-scale techno-economic feasibility of an engineered energy cane-based biorefinery. To conduct this, they used computer modelling to replicate the process under two hypothetical scenarios, determining production costs, capital investment, and output compared to soybean-based biodiesel.

Kumar said: “Although the capital investment is higher compared to soybean biodiesel, production costs are lower (66 to 90 cents per litre) than for soybean (91 cents per litre). For the first scenario, processing energy cane had overall slightly lower profitability than soybean biodiesel but yields five times as much biodiesel per unit of land.”

Steve Long, the Director of Rogue and Endowed Chair of Plant Biology and Crop Sciences at the University of Illinois, said: “Energy cane is attractive in its ability to grow across much wider geography of the US south-east than sugarcane. This is a region with much-underutilised land, yet capable of rain-fed agriculture. As a perennial, energy cane is suitable for land that might be damaged by annual crop cultivation.

“Our research shows the potential to produce a remarkable 7.5 barrels of diesel per acre of land annually. Together with co-products, this would be considerably more profitable than most current land use while having the potential to contribute greatly to the national US goal of achieving net-zero greenhouse gas emissions by 2050. This proves how valuable it is to build on the successes already achieved in bioengineering energy cane to accumulate oils that are easily converted into biodiesel and biojet.”