Emma Master, PhD, from Aalto University details how the BioUPGRADE project drives state-of-the-art innovations in biocatalysts.

The overarching goal of the BioUPGRADE project is to establish biocatalysts for bio-based material manufacturing. In so doing, we are leveraging the exquisite selectivity of enzymes to maximise the efficient use of renewable bioresources.

Defining the bioeconomy

The ‘bio’ in ‘bioeconomy’ is a reaffirmation of an economy as a system that supports the

management and distribution of ecological and environmental processes. Bioeconomies recognise that addressing human needs and wants in an ecological and environmental context requires us to reduce reliance on products from fossil origins by getting smarter about how we use renewable bioresources.

Renewable bioresources are materials in our environment that naturally regenerate in decades or less through the action of living organisms that convert sunlight and CO2 into biological structures (e.g., plants, photosynthetic bacteria and algae) or otherwise contribute to the balanced global carbon cycle (e.g., heterotrophic fungi).

Renewable bioresources comprise a spectacular array of functional materials and chemicals, from wood and agricultural fibre to antibiotics. The biological activities that make renewable bioresources in land and ocean ecosystems capture roughly five gigatonnes of carbon per year. A significant fraction of this carbon is transformed into structural biofibres like lignocellulose and chitin. Indeed, the corresponding polysaccharides represent Earth’s most abundant source of natural polymers.

Although reducing societal reliance on fossil resources through more intelligent use of renewable bioresources may seem obvious, there is concern that bioeconomies could negatively impact biodiversity and land use.

In response, bioeconomies are increasingly restated as circular bioeconomies where ‘circular’ affirms sustainable management of renewable bioresources to protect natural habitats. In our view, sustainable use of renewable bioresources means developing and deploying technologies that make smarter use of the carbon already fixed in major biofibre structures.

Role of biotechnology in the bioeconomy

Biological systems are circular by nature, where living organisms drive our planetary carbon cycle via biocatalysts that transform CO2 into an enormous array of diverse and functional molecules. Genomics initiatives continue to reveal the untapped biocatalytic potential encoded in living organisms, inspiring options for sustainable industrial processes and renewable bio-based products.

Those of us working on biotechnologies that support bioeconomies will recognise that, so far, most examples of industrial enzymes for bioresource (i.e., biomass) processing breakdown biomass structures like cellulose to sugars to be fermented to commodity fuels. The conventional emphasis on bio-derived fuels and drop-in commodity chemicals is seen as a way to align market sizes and bioresource volumes.

Alternatively, rather than deconstructing the existing materials to monomers for use as fuels or precursors for rebuilding, we envision clearer pathways where biotechnology is utilised to tweak and tailor intact biomass structures for use in broader application areas. In line with the circularity vision, this approach aims to maximise the utilisation and re-utilisation of the material with the minimum possible process requirements.

Our focus in the BioUPGRADE project is to develop biocatalysts that tailor the performance of major biomass structures, such as cellulose, hemicelluloses and chitin, to permit broader use of the carbon already fixed in these plentiful and naturally occurring biofibres.

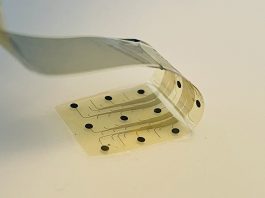

Specifically, BioUPGRADE technologies leverage the selectivity of enzymes to control the flexibility, rheological and adsorptive properties of the biofibres, permitting their use in value-added applications, including sustainable textiles, packaging and personal care products. To achieve the fundamental and applied project goals, our team assembles academic and industrial expertise in computational science, biosciences and material sciences and establishes all too rare bridges between disciplines that operate at vastly different scales (from nano to macro scale).

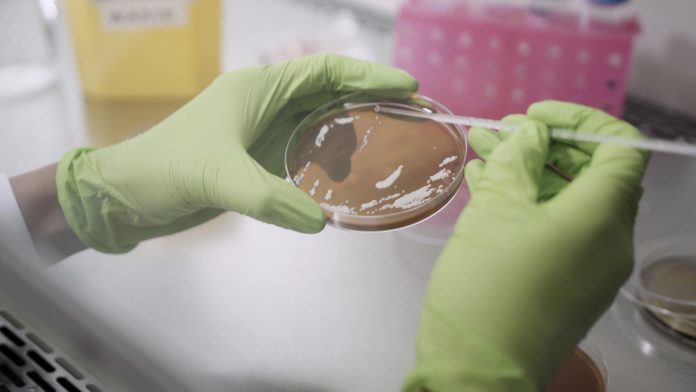

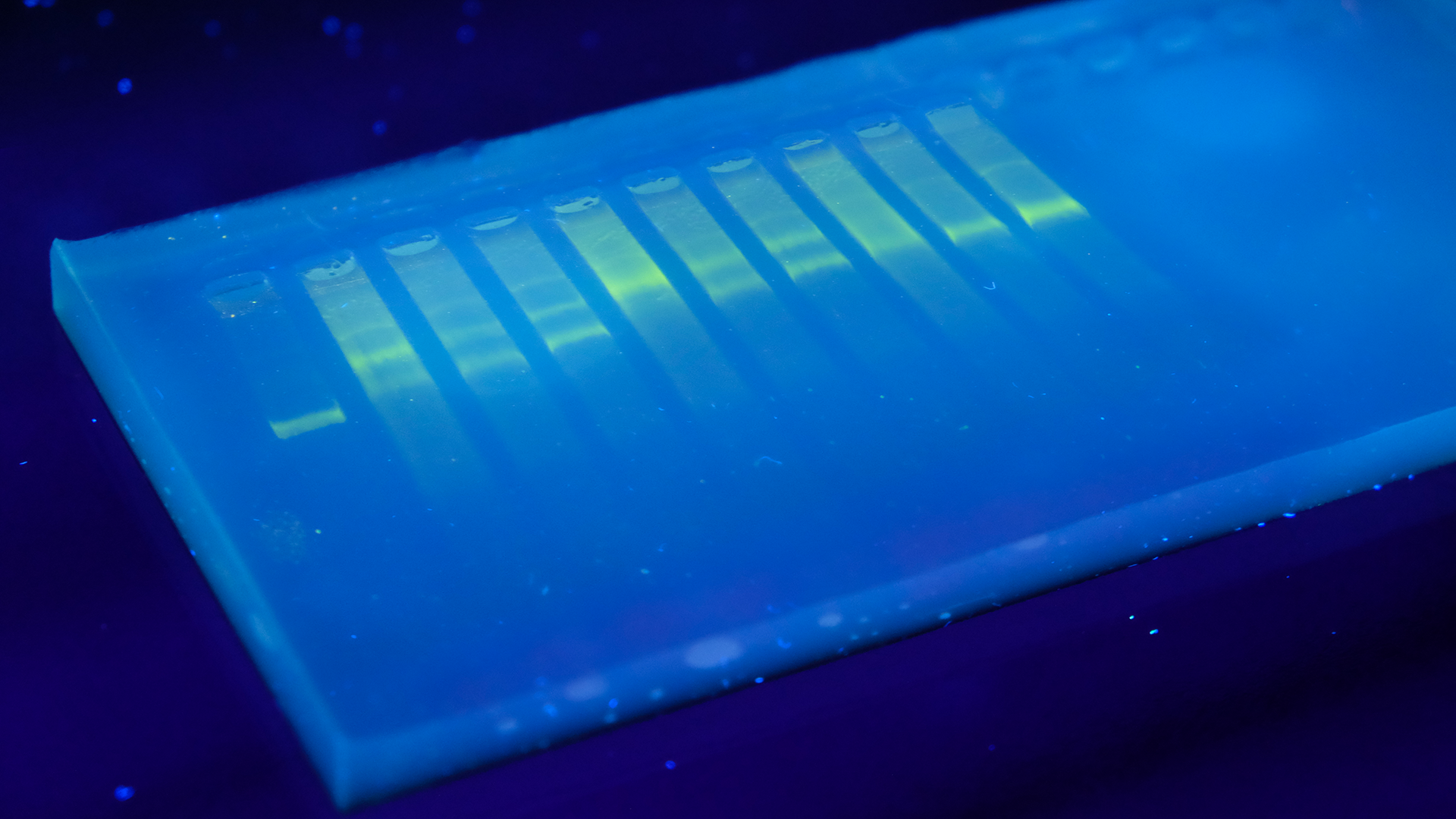

A key requirement of enzymes that tailor major forms of natural biopolymers and fibres is activity at solid-liquid interfaces. Four protein families that displayed this capability and were prioritised in BioUPGRADE are microbial expansins, lytic polysaccharide monooxygenases (LPMOs), carbohydrate oxidases and transaminases.

Microbial expansins are non-lytic proteins homologous to plant expansins that disrupt noncovalent bonds at load-bearing junctions between cellulose microfibrils and matrix biopolymers within plant cell walls, enabling plant cell wall development. Given their non-lytic mode of action and potential to disaggregate cellulosic structures, we are exploring their potential to promote cellulose fibrillation and dissolution, which is needed for sustainable textile manufacturing. Certain LPMOs and carbohydrate oxidases introduce carbonyl functionalities into lignocellulosic and chitinous materials, which can serve as reactive handles for fibre cross-linking relevant to reinforcing recycled fibre and stabilising hydrogels used in health and personal care products. We have shown that transaminases can be used in combination with carbohydrate oxidoreductases to create aminated polysaccharides from plant sources. The amine groups introduced to the fibre surfaces open applications in conductive and antimicrobial materials.

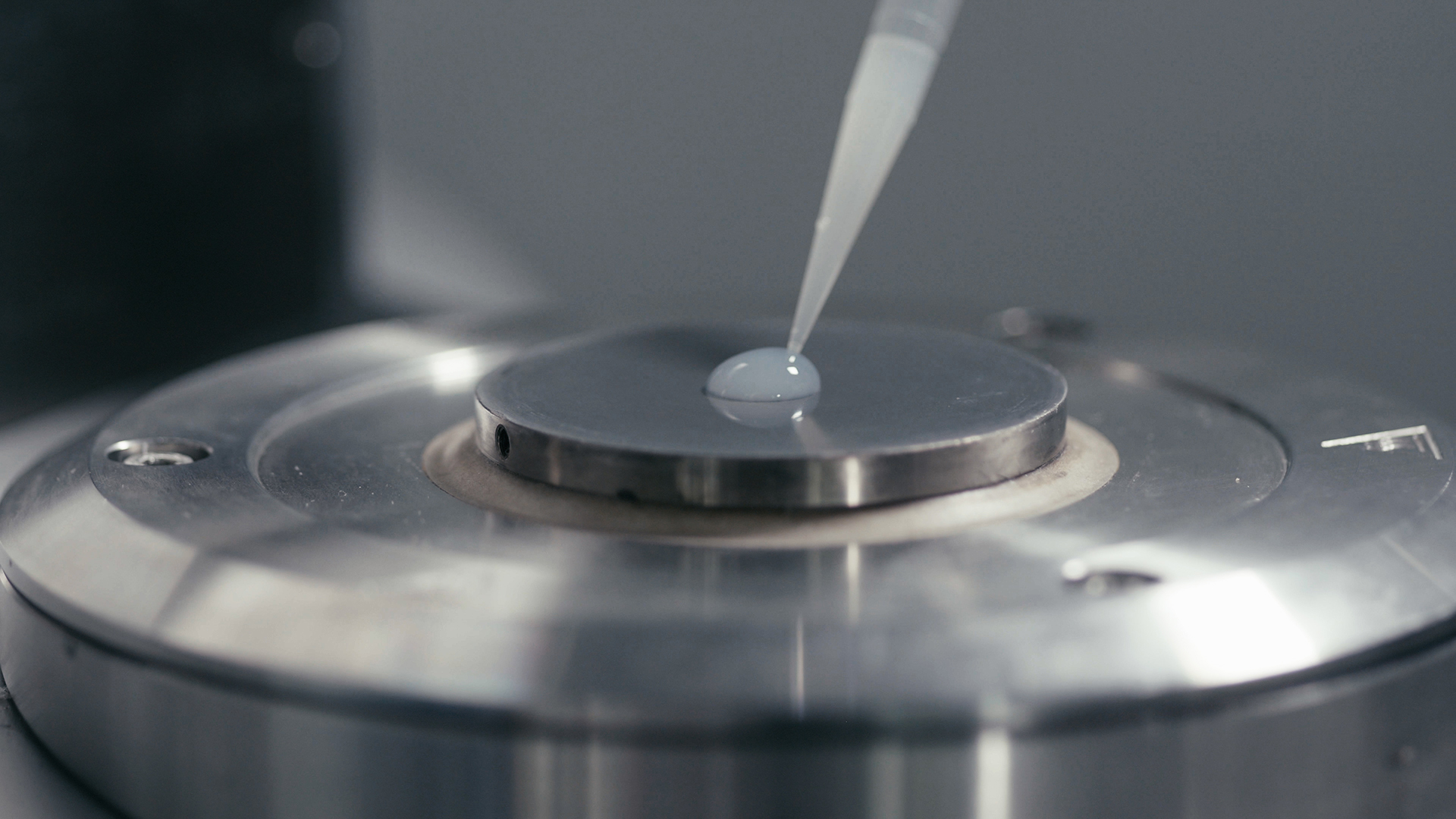

Challenges to optimising biocatalysts for materials engineering lie in uncovering molecular signatures of enzymes that act on solid surfaces and establishing application-driven screens that incorporate relevant substrates and scalable measures of material performance. We are tackling these challenges using molecular evolution, global homology detection approaches, and molecular dynamics simulations to prioritise and design enzymes that act at liquid-solid interfaces. The recombinantly produced enzyme selections and designs are then screened using biophysical methods that measure change in fibre surface charge, viscoelasticity, and morphology.

Critically, our focus on tailoring and upgrading natural biofibre structures preserves the exquisite multiscale organisation and structural properties of the biofibres that nature has evolved. As a result, the biocatalysts used to tailor biofibre properties also function as tools to uncover the hierarchical structure of the starting materials. This insight will, in turn, inform the assembly of the modified materials to achieve the desired functional properties of the project’s demonstrator applications.

Demonstrator applications

The BioUPGRADE project has three demonstrator applications:

• Sustainable textiles;

• Conductive inks for packaging materials; and

• Customised hydrogels for health and personal care.

In addition to building from the team’s expertise in technology scale-up and deployment in these areas, the demonstrator applications were selected for their potential to support a cascade of bioproducts and the anticipated alignment of market size, bioresource supply, and process cost.

The increasing consumption demands for textiles are expected to have detrimental environmental impacts through greenhouse gas emissions and water and land use. BioUPGRADE aims to demonstrate sustainable textile alternatives by utilising biocatalysts to enhance the dissolution and spinnability of major and renewable sources of lignocellulosic fibre. As enzymes are known to be eco-friendly options, the environmental impact of textile manufacturing will also be reduced.

Metal-free conductive inks are needed to facilitate the recycling and reuse of packaging materials. Graphene has been used for this purpose. However, graphene shows low adherence to common packaging materials. BioUPGRADE addresses this limitation by providing solutions based on transforming structural biopolymers into adhesion matrices.

Hydrogels for advanced biomedical and personal care applications still rely largely on synthetic polymers produced from fossil-based resources. BioUPGRADE aims to combine the use of structural biopolymers and biocatalysts to create hydrogels with structural stability and added bioactivities such as antioxidant and antimicrobial properties important to biomedical and personal care applications.

In summary, BioUPGRADE is establishing a bio-customise framework that leverages genomics data, biocatalytic selectivity, and the carbon and energy already fixed as nature’s major structural polymers to make strong scientific and technology impacts that establish European leadership in the early exploration of lasting, sustainable technologies.

Please note, this article will also appear in the fifteenth edition of our quarterly publication.