Brazilian Critical Minerals is an emerging Brazilian rare earth and platinum group metal developer set for rapid growth.

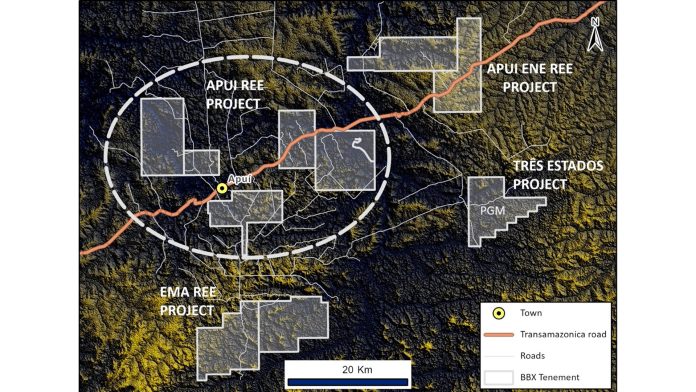

Brazilian Critical Minerals (BCM-ASX) is an Australian technology and critical mineral developer with strategic assets in Amazonas, Brazil, near the Town of Apui. The very large portfolio contains one platinum group metal (PGM) project covering slightly over 340 hectares and three rare earth element (REE) projects covering approximately 720km².

Its Três Estados PGM discovery, which is only 9% explored, currently has a 725,300-ounce JORC resource containing gold (Au), platinum (Pt), palladium (Pd), iridium (Ir), and rhodium (Rh), and its EMA and ENE Apui REE discoveries are in the final stages of calculating a JORC resource for both, with Eme being the largest.

The company began in 2011 as BBX Minerals with what was believed to be two gold discoveries – Ema and Três Estados. The company name has recently been changed from BBX Minerals to Brazilian Critical Minerals. Given that the company now pursues advanced technology, PGMs and REEs, the name Brazilian Critical Minerals perfectly describes what the company is all about. Striving for sustainability and providing critical elements for achieving a carbon-neutral future.

The rare earth discovery at Ema changed the course of the company both because of its grade and the fact that the deposit was ionic. Hence, the search for more rare earths in the surrounding area began in earnest, staking rare earths on nine separate tenements, later split into three projects:

• EMA PROJECT (Ema and Ema East) with 189km² of felsic volcanics, rhyolite, with regolith-hosted ionic adsorbed clay rare earths confirmed by ammonium sulphate leach tests. Similar to the Chinese REE deposits.

• APUI REE PROJECT with 358km² to be explored for REEs hosted in regolith developed over sediments with a specific radiometric signature, similar to the Makuutu deposit in Uganda.

• APUI ENE REE PROJECT with 173km² of flat-lying sediment, which is older than those at the APUI REE PROJECT. The first unit that was drill tested at APUI 2400 ppm.

EMA ionic REE project: Chinese-style

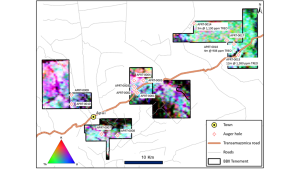

An aggressive exploration programme for ionic rare earths following up the discovery of REEs in the felsic volcanics and pyroclastics regolith at Ema was conducted on the Ema and Ema East leases.

The EMA iREE project (Ema and Ema East leases) is unique amongst Brazilian REE projects in that it shares almost identical characteristics with the iREE deposits developed over felsic volcanic rocks in southwest China, the world´s largest known ionic clay region.

These leases comprise 189km² of felsic volcanic over which 142 auger holes totalling 2,048m have been completed to date. A further 53 auger holes totalling 701m have been completed at Ema East, testing a total of 82km² or 43% of the regolith developed over the felsic volcanics (Fig. 2).

The initial results for 39 auger holes from the regional reconnaissance programme showed the presence of exceptional iREE grades of less than three metres in excess of 1,200 ppm TREO (e.g. TR-059 (Table 1), with accompanying elevated values of NdPr oxides, demonstrating the presence of high-grade zones within this major and widespread ionic rare earth deposit, which remains open in all directions (Fig. 3).

TREO grades >1,000 ppm are widespread, containing >100 ppm NdPr and ten ppm TbDy oxides. All holes that intersected the enriched iREE horizon ended in high TREO values, indicating significant upside potential for high-grade material at depth.

Significant results:

• Six metres @ 1003 ppm TREO from six metres (TR-043), including three metres @ 1191ppm TREO ending in 1135 ppm TREO

• Seven metres @ 1015 ppm TREO from six metres (TR-050), including three metres @ 1266 ppm TREO ending in 988 ppm TREO

• Six metres @ 812 ppm TREO from six metres (TR-051), including two metres @ 1122 ppm TREO ending in 1182 ppm TREO

• 16 metres @ 771 ppm TREO from one metre, including three metres @ 1282 ppm (TR-059) ending in 88 8ppm TREO

• 16 metres @ 739 ppm TREO from nine metres (TR-66) including four metres @ 1120 ppm TREO ending in 1352 ppm TREO

• 16 metres @ 849 ppm TREO from two metres (TR-71) including two metres @ 1104 ppm TREO ending in 1083 ppm TREO

APUI EN REE project

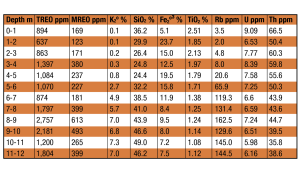

A regional reconnaissance auger drilling conducted within two leases recently granted (Fig. 4) east of Apuí located a new style of REE mineralisation associated with a sedimentary unit rich in potash. The highest-grade portion of hole APTR 013 coincides with a potash-rich zone, grading approximately 7% K2O (Table 1), interpreted as being related to a potassium-rich sedimentary horizon, potentially of significant areal extent. The hole was terminated at 12m in strongly mineralised saprolite, grading 1804 ppm TREO. The multi-element distribution along the auger hole APTR013 (Table 1) indicates that the highest TREO grades from seven metres downhole are directly correlated with potash-rich sediment (7% K2O) anomalous in rubidium, with silica and iron contents typical of a mature glauconitic sandstone which occurs in extensive marine sediments. Glauconite decomposes into halloysite, kaolin and smectite, where REEs may be ionic or colloidally hosted. Uranium and thorium are low and compatible with ionic rare earth mineralisation.

Significant results:

• 12 metres @ 1,380 ppm TREO from the surface, including five meters @ 1,942 ppm TREO from seven metres (APTR 013)

• Three metres @ 1,130 ppm TREO from the surface (APTR 014)

• Four metres @ 908 ppm TREO from the surface (APTR 018)

Três Estados precious metals project

Tres Estados started life as a gold project with assaying difficulties, and even though native metal that resembled could be seen in the core, fire assays could not detect gold or silver. It turned out, after much SEM work, the native metal was a unique alloy containing gold, platinum, copper, lead and occasional minimal amounts of osmium and iridium, which readily explained why fire assay did not work – so what would work was there an assay method for this type of metal occurrence.

There were metallurgical tests using smelting methods utilising five-kilogramme mineral samples and copper sulphate that did return assays for precious metals. These metallurgical tests were expensive and could not be used as an assay for JORC purposes, so an assay method needed to be developed.

After many years, a nickel smelt prep followed by a fire assay was developed and accepted as an assay procedure. This procedure required ten grams of mineral to be combined with laboratory-grade nickel and several fluxes to be brought to 15400C for ten minutes, which formed a nickel button. The nickel button was then dissolved in four different acids and fire-assayed for Au, Pd, Pt, Ir, and Rh, the sum of which was the basis for the existing resource, containing 725,300 ounces of combined gold, platinum, palladium, iridium, and rhodium. While the overall grade was above one gram and quite valuable because of the rhodium and iridium, the company, believing there was more there and the assays were understating the metal content, began looking for enhancements and a production method.

Ecobiome, a microbe leaching company based in Texas, came to management’s attention as a way to enhance the recovery and work as a process solution. Testing began in late 2022 and was finalised in June of 2023, indicating that Ecobiome’s proprietary microbes could achieve both enhanced recovery and production.

The final test was conducted in May of 2023 utilising drill hole TED-20, a Três Estados metallurgical test hole. The result of a 108-hour leach test utilising two of EcoBiome’s microbes that were designed to work in tandem, with one breaking down the mineral particles and the other recovering the precious metals. The results were spectacular, with a ten-fold increase in metal recovered over the nickel smelt assay. What was then BBX’s Catalão lab received 50kg of the bioleached matter for further production and recovery test work. Ultimately, of the plus 16 grams of gold and palladium released by bioleach 98% of the gold was recovered and 94% of the palladium was recovered by cyanide leaching method apply to the bioleached material. From this work, a decision was made to utilise Ecobiome’s bioleaching process to aid in re-assaying the Tres Estados resource starting at Tabocal.

All the necessary laboratory equipment and infrastructure for conducting bioleach assaying and pilot plant testing has been acquired, assembled and commissioned in the Catalão laboratory. The equipment includes nine 35-litre reactors for conducting bioleach assays (see Fig. 4) and a larger pilot plant reactor. The finalisation of the importation of the required materials from EcoBiome in Texas is currently in progress, with the commencement of routine assaying of Três Estados drill holes scheduled for early Q1 2024.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.