From concept to formulation, manufacturing to application, Graphene Composites offers global brands breakthrough technology to solve key technical challenges through nanomaterials engineering.

By definition, nanomaterials are tiny. They are less than 100 billionths of a metre in size and shorter than the wavelength of visible light. At these tiny scales, normal Newtonian physics ceases to apply, and quantum physics kicks in. The rule of thumb at the nanoscale is that the smaller something is, the more powerful it can become, provided that you get the nanomaterial engineering right.

That is where Graphene Composites (GC) is unique, even in the nanomaterials world. While there are now many suppliers of graphene and other nanomaterials in the global markets there are far fewer companies who have the expertise and experience to work with these nanomaterials so that they perform as desired.

“Success will not be measured by how much a consumer understands nanomaterial engineering or even what the materials we engineer do – it will be measured by working with the world’s leading brands to create products that make people’s lives better.”

(Steve Devine, CTO, GC)

Commercialising revolutionary technology

Nanomaterials engineering technologies are, by their nature, revolutionary. By making things in a new way, they can achieve previously unimaginable results. Many customers and most manufacturing supply chains will, at first, find revolutionary technologies quite uncomfortable. Overcoming technical challenges to solve real-life problems and deliver commercial benefits is the holy grail for many companies – ultimately taking time, money, and effort to get there.

That is where GC can help. We have a core expertise in functionalisation, in manipulating the molecular structures of graphene and other nanomaterials so that they can be used to improve the performance of a wide range of products.

GC was co-founded in 2016 by married couple Sandy Chen, City analyst turned entrepreneur, and Carol Jarvest, a marketing executive. Combining the world’s strongest material, graphene, with aerogel, the world’s lightest material, they developed ballistic protection that is stronger, lighter, and more resilient than those already in the marketplace. Former Principal Scientist at the UK Graphene Application Centre, Chief Technology Officer Dr Stephen Devine, quickly joined to lead GC’s technical team from the beginning.

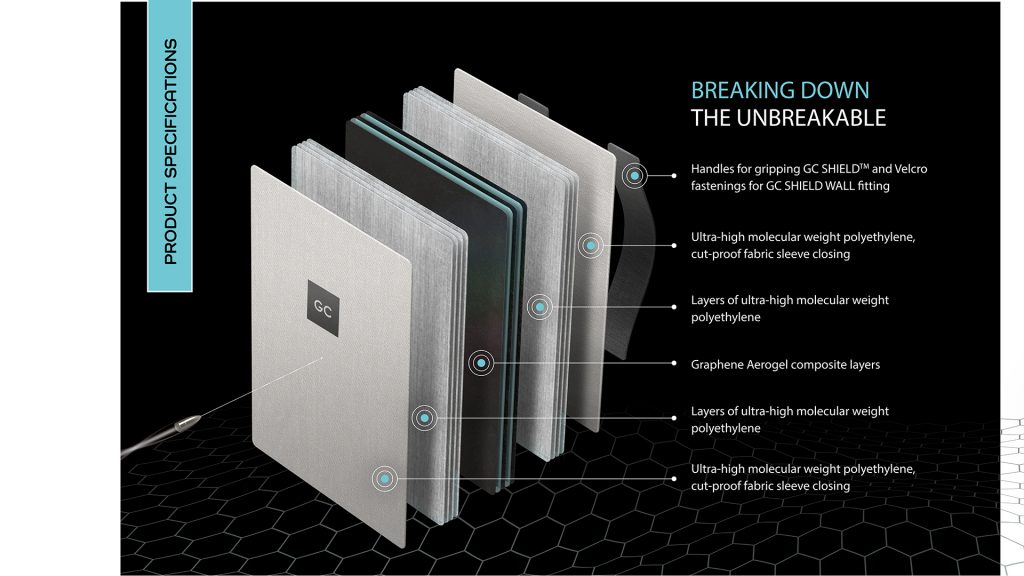

GC is one of those few nanomaterial engineering companies that have successfully turned promising ideas into real commercial products. First we developed our GC Shield™, a graphene/aerogel composite bulletproof armour technology that is half the weight of conventional armour. Now we are launching our coronavirus-killing graphene oxide/silver nanoparticle formulation, GC Ink™.

Pivoting in the pandemic

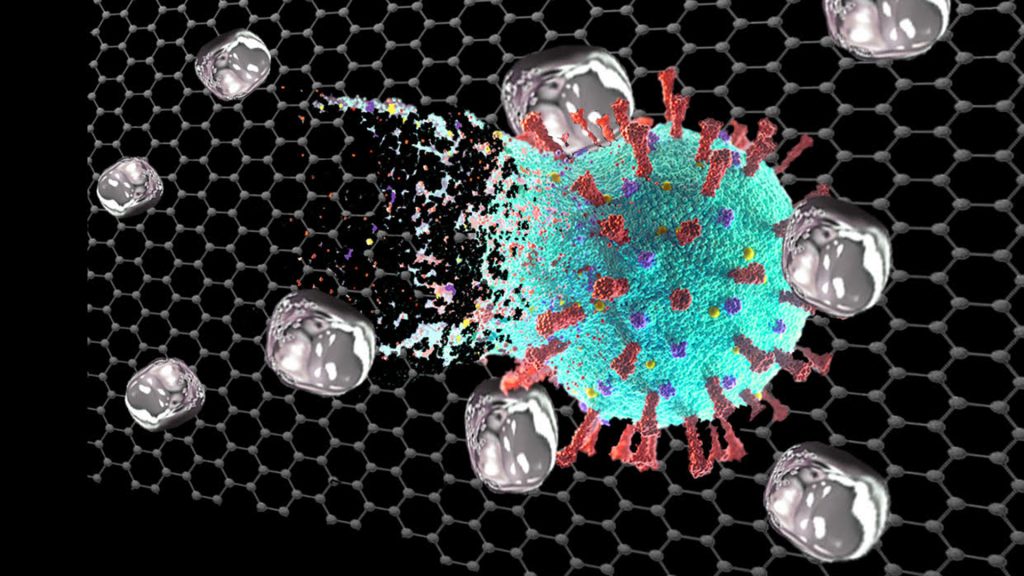

When COVID-19 struck in March 2020, GC was engaged in extending some promising research by Professor Bob Hurt at Brown University on graphene oxide formulations to prevent mosquito bites. With the pandemic taking hold, our efforts were quickly diverted and expanded to develop a coronavirus-killing ink formulation. By adding silver nanoparticles, a proven antibacterial agent, to the graphene oxide formulation, we aimed to develop a virucidal graphene oxide/silver nanoparticle ink that could neutralise the SARS-CoV-2 coronavirus that causes COVID-19.

Life and death R&D – developing our coronavirus-killing ink

Cramming an estimated three years’ R&D into one year, we fostered a close and collaborative partnership with Brown University who undertook the virucidal efficacy testing, and with the UK Centre for Process Innovation (CPI), and Thomas Swan & Co in the UK who both assisted with the formulations work.

By the end of an exhausting 2020, we had developed a graphene oxide/silver nanoparticle formulation that Brown University had tested to show 100% virucidal efficacy in one minute versus Human Coronavirus OC43 and Influenza A H1N1 virus in liquid form. Brown published this report on the bioRxiv pre-print server in March 2021.1

The technology is highly effective due to its dual-action mechanism: the negatively-charged surface of graphene oxide traps the positively-charged parts of water droplets and the protein spikes on coronavirus and other viruses. The silver nanoparticles oxidise the lipid membrane protecting coronavirus RNA, thereby killing it.

A nanotechnology invention to address a real-life challenge: making the air we breathe cleaner and safer

Recently, focus has turned to the issue of ventilation and air quality. Viruses, including coronaviruses, spread through fine aerosols, highlighting the need for innovative measures to suppress the transmission of these airborne infectious pathogens. The application of the virucidal ink to air filters can make the air we breathe cleaner and safer by trapping and killing viruses and bacteria in the airflows. Air filters that can trap and kill viruses and bacteria in ventilation systems is essentially a new invention. Up until now, air filters could only filter out some of the particles that were carrying viruses and bacteria.

The virucidal ink has recently been independently tested for antiviral activity on textiles and certified to at least 99% virucidal efficacy, according to ISO 18184:2019. However, existing regulatory and testing regimes are not designed to handle revolutionary technology. This is the next set of hurdles innovators and governing bodies face – such is technological progress.

Strongest, lightest, most resilient

Our original product development, the Shield technology, has enabled us to launch a range of armour products that offer high levels of ballistic and stab protection.

What makes GC Shield™ technology special is a solution that we use called ‘hypersonic shear thickening’. With ‘shear thickening’ materials, the harder you hit them, the harder they get. ‘Hypersonic’ means that it works with projectiles hitting at several times the speed of sound – such as high-velocity bullets. Our patented armour is designed to use the impact force of a bullet against itself – so much so that many high-powered rifle rounds actually disintegrate within our GC Shield. This is also what makes it so good at force dispersion, which means there is much less back-face deformation on the back of our shields and therefore, far less damage to someone behind a GC Shield than with other shields.

We have recently launched a significantly stronger version of the Shield, the GC Patrol Shield, that stops multiple rounds from automatic weapons like AR-15 and AK-47 assault rifles. We are making this product available only to authorised police and military forces.

Composite performance

Given the performance, it only makes sense that this technology is transferable to any product where strength, weight, and shock resistance is an important element – such as in Formula 1 vehicles, aircraft, and wind turbine blades.

GC is applying the Shield technology to composites so that they have a similar performance as carbon-fibre composites but are much lighter. Using a comparable production process to that used in carbon fibre components, graphene-infused polymer, aerogels, and other materials will be made into a strong, lightweight material to provide a higher degree of shock and impact resistance than other composites.

GC’s philosophy

Our philosophy has two main ingredients. Firstly, our ‘one team’ approach and the kindness with which we treat each other. Secondly, a ‘fail fast’ approach where we are prepared to try different ideas and move on quickly if it does not work – the result of which is an agile and effective product development process.

Fundamental to our model are the successful partnerships we have developed across global research, academic and manufacturing organisations and our ability to apply a highly focused, efficient, and agile R&D process to bring products to market.

They are the reason we have won awards and innovation funding over the last 12 months – including the Mass Challenge Platinum Award, a global accelerator and entrepreneurship programme as well as funding by the State of Rhode Island to set up our research and manufacturing centre in the US. And more closely in Europe, we have been awarded Eureka funding as part of a consortium to develop and test virucidal, antimicrobial and anti-fungal coatings.

“You really build a trusting relationship when working through challenging tasks. We have formed the strongest relationships with partners, suppliers and customers when working together to solve a problem.”

(Sandy Chen, CEO, GC)

References

- Graphene oxide/silver nanoparticle ink formulations rapidly inhibit influenza A virus and OC43 coronavirus infection in vitro Meredith J Crane, Stephen Devine, Amanda M Jamieson

Please note, this article will also appear in the eighth edition of our quarterly publication.