Albert De Roeck, senior research scientist at CERN, spoke to Innovation News Network’s digital editor, Caitlin Magee, about the EP-Neutrino group and its 3D printed neutrino detector, SuperFGD.

The CERN EP-Neutrino group aims to develop a new plastic scintillator production technique using additive manufacturing for the production of a plastic cube detector, named SuperFGD. This work will be carried out in collaboration with experts in the development of scintillator materials, the Institute for Scintillation Materials (ISMA) of the National Academy of Science of Ukraine, and the Haute École d’Ingénierie et Gestion du Canton de Vaud (HEIG-VD), industry leaders in additive manufacturing.

Albert De Roeck, senior research scientist at CERN and leader of the CERN EP-Neutrino group, spoke to Innovation News Network’s digital editor, Caitlin Magee, about the EP-Neutrino group and a new CERN-led international collaboration which will develop 3D-printed neutrino detectors.

Key features of the SuperFGD

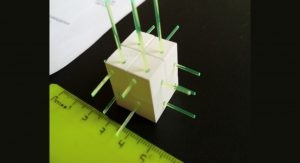

Plastic scintillators are one of the most used active materials in high-energy physics. The scintillating light reveals the passage of a charged particle. When a sufficiently granular detector can be built, trajectories of charged particles can be detected. Neutrino detectors aim to detect interactions of neutrinos with the matter of the detector, which must be dense enough as neutrinos interact only very weakly. Plastic scintillator is typically a good material for that. To be able to characterise the particles produced in the interaction the proposed neutrino detector here will consist of plastic cubes of dimension 1x1x1cm3 read out by horizontally and vertically oriented optical fibres, allowing the identification of the individual cubes that have fired along the trajectories of the charged particles. The smaller the cubes, the more precise the results will be.

The plastic cube detector, named SuperFGD (for super fine granularity detector) will be located at the centre of the so called near detector ND280 of the T2K neutrino experiment in Tokai, Japan, and will be surrounded by additional particle detectors based on different technologies. The novel SuperFGD detector will have a two-tonne polystyrene-based plastic scintillator detector segmented in a total of around two million cubes, each of these need to be produced with identical optical quality and within 100 micrometre geometrical dimension tolerances, be optically isolated and contain grooves at specific precise locations to allow for the passage of the read-out optical fibres. The cube production and assembly of such a detector is a huge challenge.

This novel detector design is also a prime technology candidate for the near detector of the DUNE neutrino experiment presently under design and construction in the US and will be roughly six times larger than SuperFGD. This is where the 3D printing technology comes in: the production and automatic assembly of modules (consisting of say 10,000 cubes) of optically isolated cubes.

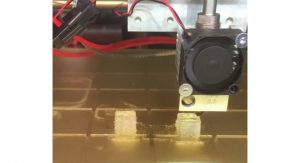

The final goal is to 3D-print a ‘super-cube’, that is, a single massive block of scintillator containing several thousand optically independent cubes. 3D-printing would solve the issue of assembling the individual cubes, which could thus be produced in any size, including smaller than 1cm3, and relatively quickly. So far, the collaboration has been fruitful. The first results established the proof of concept: the scintillation light yield of a polystyrene-based scintillator 3D-printed with fused deposition modelling has been found to be comparable to that of a traditional scintillator. Other, e.g. laser-driven, techniques are being explored as well.

In my team the key scientists involved in this project are Davide Sgalaberna (previously CERN now ETH Zurich) and Umut Kose (CERN), who have been driving much of the practical work and organisation.

The benefits of the ‘super-cube’

Neutrino detectors are generally very massive, due to the minimal interactions between neutrinos and matter. This means a lot of material is required to get a data sample with sufficient statistics of neutrino interactions. In practice, so called long baseline neutrino experiments consist of two parts. One part is the near detector which is located a few hundred metres away from the neutrino source. The other part is the far detector which can be located several hundred to over a thousand kilometres away from the neutrino source. The detector concept discussed here targets at this stage a design for a near detector with a mass of about 10 tonnes. The 3D printing technology will allow the automatic production of modules of cubes, with precise geometrical dimensions, programmable shapes e.g. to contain the grooves for the passage of the optical readout fibres or other than the standard cubic shapes depending on the overall detector geometry, all with optical qualities (transparency etc) required by the experiment, and optical isolation e.g. using two component printing. All this can be done in a very cost efficient and time saving manner. A pioneer of this detector technology for a neutrino detector is the SoLid experiment currently running at the BR2 reactor in Belgium. This experiment consists of about 12,000 plastic cubes of dimension 5x5x5cm3 that needed to be individually cleaned, inspected, optically isolated, and assembled, an effort that took several man-years. This would not scale for a more granular detector. 3D printing is a clearly an optimal solution.

Scintillator detectors are not only used in particle physics but in many fields of science including medicine. Demonstrating the feasibility and production practicality of this detector will open the doors to also use this technology in other fields. We noticed a clear interest in the science community in our results already. .

The main goals of the CERN EP-Neutrino group

The general goals of the CERN EP-Neutrino group is to take part in accelerator-based neutrino experiments, in Japan and the US where the centre of gravity is and will continue to be in the future. The physics goals are to unveil the properties and interactions of this still mysterious and ghostly particle in detail. This is expected to give us deeper insights in fundamental questions such as why our Universe does not contain as much matter as anti-matter, as naively expected from a Big Bang origin, and perhaps what the nature of the even more enigmatic dark matter could be. Personally I also anticipate that through these measurements, we will get further evidence on clear signals which are not part of the present ‘Standard Model of particle physics’, and which will teach us what is lying beyond. Neutrinos, over the last few decades, have presented us with a number of unexpected surprises already, and I firmly believe we have not seen the end of that yet: new high quality experimental results will lead to new surprises. I note also that a very important activity of the neutrino programme at CERN is the Neutrino Platform, a platform for research and development, and assembly and possible testbed for detector components of neutrino experiments worldwide. Also, the theory department has an explicitly neutrino activity.

Together, these three activities play a strong role as a beacon for European neutrino activities.

Since its launch the EP-neutrino group at CERN has been involved in international collaborations, as are all other experimental endeavours at CERN For example, the DUNE collaboration included more than 1,000 scientists from about a two-hundred institutes. Particle physics is traditionally a field where international collaboration has been a key part to the success since many decades. For the 3D printing initiative, which is a smaller scope endeavour, we are a multi-institute collaboration with industrial partners in Europe so far, but we have already been approached by more international partners for collaboration.