A research team from the U.S. Department of Energy’s Pacific Northwest National Laboratory has developed a sodium-ion battery with greatly extended longevity in laboratory tests.

Sodium is a chemical element that is considered cheap, abundant, and a promising candidate for new battery technology. However, the limited performance of sodium-ion batteries has prevented widespread applications of this technology.

To address this issue, a research team from the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) has observed that a simple shift in the ingredients that construct the liquid core of the battery prevents the performance issues typically encountered in sodium-based batteries. The results of this study were recently published in the journal Nature Energy and provide a promising process for a battery that could potentially power electric vehicles (EVs) and store energy from the Sun.

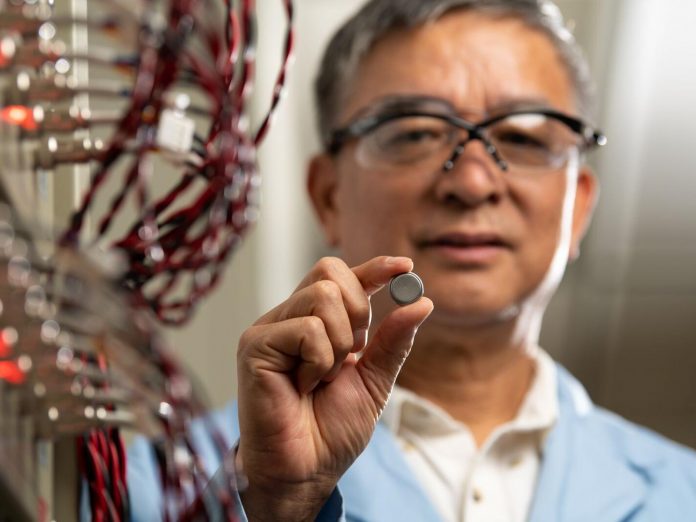

“Here, we have shown in principle that sodium-ion batteries have the potential to be a long-lasting and environmentally friendly battery technology,” explained Jiguang (Jason) Zhang, lead author from PNNL, and a pioneer of battery technologies with more than 23 patented inventions in energy storage technology.

The Department of Energy’s Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office, supported the study. Imaging studies were performed at the Environmental Molecular Sciences Laboratory, a DOE Office of Science User Facility at PNNL sponsored by the Office of Biological and Environmental Research.

Creating sodium-ion batteries: Assembling the correct ingredients

An electrolyte is an element that keeps the energy flowing within the battery; it is formed by dissolving salts in solvents and generating charged ions that flow between the positive and negative electrodes. As time passes, the electrochemical reactions responsible for maintaining the energy flow become sluggish, meaning that the battery cannot recharge. Currently, in sodium-ion battery technologies, this process occurs much faster than in lithium-ion batteries.

PNNL scientists tackled this problem by substituting the liquid solution and the type of salt flowing within to create a novel electrolyte recipe. Laboratory tests revealed that this new design is durable, as it held 90% of its cell capacity after 300 cycles at 4.2V, which is higher than most of the sodium-ion batteries previously recorded.

Additionally, the existing electrolyte process for creating sodium-ion batteries results in the protective film on the negative end – or the anode – dissolving over time. This film is considered critical because it allows sodium ions to pass while preserving battery life. The PNNL research team’s new technology stabilises this protective film and the new electrolyte generates an ultra-thin protective layer on the positive pole – or the cathode – that contributes towards additional stability of the entire unit.

A naturally fire-extinguishing solution

Furthermore, this technology utilises a naturally fire-extinguishing solution that is resistant to temperature changes and capable of operating at high voltages. A critical key to this feature is the ultra-thin protective layer that forms on the anode – it remains stable once formed and provides the longer battery life scientists intended to create.

“We also measured the production of gas vapour at the cathode,” said Phung Le, a lead author of the study and a battery chemist at PNNL. “We found very minimal gas production. This provides new insights to develop stable electrolyte for sodium-ion batteries that may operate at elevated temperatures.”

Further developing sodium-ion battery technology

Despite these developments, sodium-ion technology is still behind lithium regarding energy density. However, scientists have noticed the advantages, such as imperviousness to temperature changes, stability, and long cycle life. These are considered valuable features in applications of specific light-duty EVs and grid energy storage in the future.

PNNL researchers intend to continue to refine their design for this battery technology. The team is experimenting with other techniques to reduce – and eventually eliminate – the requirement to include cobalt, which is toxic and expensive if not recovered or recycled, concluded Le.