Dynelectro holds the key to a unique technology that can become a game-changer within Power-to-X. The dynamic high-temperature electrolysis has now been running for more than half a year and shows impressive results.

Danish innovation firm Dynelectro has progressed well during the Power-to-X revolution and stands to become one of the significant players in what could become Denmark’s next green export adventure. The Zealand company has developed a technology that converts water into hydrogen 25% more efficiently than what is possible with current technology. Thus, there is a prospect that the technology will soon be able to provide a green and competitive alternative to fossil fuels.

Karsten Klemens Hansen, Chemical Engineer and COO at Dynelectro, said: “Hydrogen will play a crucial role in the parts of the transport sector of the future that are not possible to electrify, including aviation and shipping. The hydrogen we produce can be used both as an energy source in the industry but also as a building block for e-fuels. Therefore, it is crucial that we step on the accelerator and succeed with this transition if we want to have green air under our wings soon.”

Now, the technology will be field tested at the port of Kalundborg, Denmark, situated in the northern part of Zealand

An economic challenge

Power-to-X is about converting power from renewable energy sources into green hydrogen. The prerequisite for large-scale hydrogen production, which is the core of Power-to-X, is energy and ultrapure water in large quantities. If hydrogen is to be used in e-fuels (i.e., methanol), there is also a need for green CO2.

The reason why green fuels have not yet been adopted on a large scale is that it is about three times more expensive to produce green fuels than fossil fuels. With current technology, about half of the power is lost in the conversion from electricity to green fuel. Since electricity will account for 80-90% of production costs, the price of green fuels will be far too high. Therefore, efficient conversion is essential if we are to make green hydrogen and green fuels economically attractive.

Minimal waste and maximum power

CEO and Founder of Dynelectro, Søren Højgaard Jensen, has been researching electrolysis technology for more than 20 years and, together with the team of engineers, has developed a patented Power-to-X method that drastically reduces waste heat, extends the life of the energy plant, and enables more efficient electrolysis at higher temperatures. Through more than 4,500 hours of laboratory testing on electrolysis stacks, the company has proven that it is possible to improve the performance and longevity of stacks. Now, the technology must prove what it can do in an authentic setup.

“We have been running tests on the stacks for more than half a year. Under normal conditions, the stacks would degrade rapidly, resulting in a short lifespan, but with our method, the degradation has been quite minimal. The latest results show a degradation rate that is less than we can measure and points to a lifespan of up to ten years, which opens up enormous possibilities. Now we are going to test and demonstrate the stacks outside the laboratory’s safe surroundings when we set up an electrolysis unit in a container that is connected to water utility firm Kalundborg Utility,” said Søren Højgaard Jensen.

The Power-to-X electrolysis unit at Kalundborg Utility is part of the project PtX Cluster Zealand, where five high-tech companies are testing technologies that, based on side streams from green energy, can make the production of hydrogen and green fuel substances cheaper. But the test adventure does not end here. A 0.15 MW prototype connected to a wind turbine in Jutland will subsequently test the dynamic operation.

“It is necessary to regulate power consumption and hydrogen production in line with the variations in electricity production from solar cells and wind turbines. This results in temperature variations in electrolysis plants, which increase degradation and therefore slowly destroy the plant. Our technology, which we call ‘AC:DC’, makes it possible to keep the temperature constant in the electrolysis plant, regardless of how much hydrogen is produced. In this way, we can avoid degradation and make the stacks live for up to ten years,” continued Søren Højgaard Jensen.

Scaling Power-to-X in gigawatt format

A Danish target of a 4-6 GW electrolysis capacity by 2030, as well as a huge demand on a global scale, place demands on the acceleration of scaling up. Through various projects, the technology has been tried and tested in partnership with Siemens Gamesa, Ramboll, DTU Energy, Powercon, and others. While a number of funds and investors have supported the green growth journey financially, COO Karsten Klemens Hansen expects that the technology will already be able to be implemented in 2024-2025 and create real changes in society. However, if the Power-to-X technology is to be scaled to gigawatt scale, additional investments are needed.

Karsten Klemens Hansen said: “It is a huge market, and we are up against some big players who are also busy scaling up. We have the advantage that we can extend the service life up to ten years and radically reduce waste heat. At the same time, we have a technology that can be scaled up relatively easily and thus become a good business.”

Power-to-X on speed

At Business House Zealand, which has followed Dynelectro for more than two years and acted as a sparring partner about business development, there is no doubt that the Zealand company is on the verge of an export adventure.

Thomas Østergaard Jørgensen, Business Developer at Business House Zealand, said: “Dynelectro’s patented technology is so far ahead of today’s known technologies. Therefore, it can have a huge impact on the speed and spread of hydrogen production, as well as Power-to-X in a larger perspective, both in Denmark and globally.

“In addition to the efficient and economically sustainable hydrogen production that Dynelectro stands to deliver, we in Denmark are also far ahead in development in other parts of the PtX value chain, including water technology and carbon capture. In combination with a large amount of green energy and a power grid that can transport it, I think we will be able to see an effect of Power-to-X already within five years.”

NB: Original article prepared by Business House Zealand and translated with permission.

About Dynelectro

Founder Søren Højgaard Jensen has been researching Power-to-X electrolysis technology for more than 20 years and started Dynelectro in 2018. Samantha Jane Phillips joined as co-founder (and CCO) with more than 25 years in global resource developments with Fortune-500 firms.

The company is located in Viby Zealand and collaborates with Ramboll, DTU Energy, Siemens Gamesa and AAU, has received support from, among others, the Ramboll Foundation: Flemming Bligaard, EUDP and Innovation Fund Denmark, and has been awarded a number of green awards.

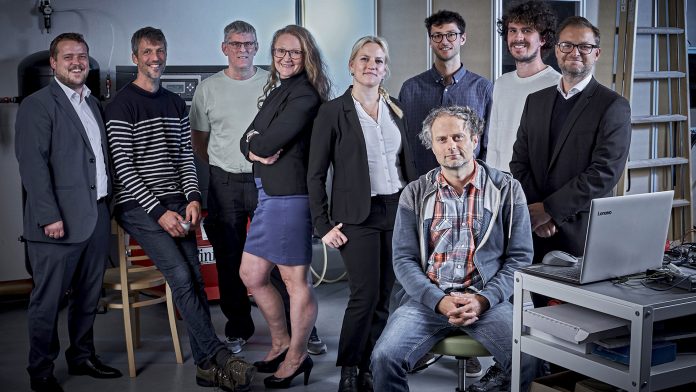

Dynelectro currently has nine employees but is expected to grow significantly in the coming years as they expect to be able to accept commercial orders for delivery in 2025. Among the employees is physics engineer Anne Lyck Smitshuysen, who is featured on Forbes’ European ‘30 under 30’.