Scientists at JAIST have used motor proteins to create microrobots with artificial muscles that could be produced using 3D printing.

The team from Japan Advanced Institute of Science and Technology have developed a strategy compatible with 3D printing to activate millimetre-scale robots with artificial muscles using genetically modified biomolecular machinery.

The cells of lifeforms contain a variety of complicated compounds called molecular motors. These biological machines are pertinent for types of movement in living systems such as the transportation of proteins in a single cell to the macroscopic contraction of muscle tissues.

At the intersection of robotics and nanotechnology lies the challenging objective of discovering how to leverage the action of molecular motors to perform larger tasks in a controlled manner.

“So far, even though researchers have found ways to scale up the collective action of molecular motor networks to show macroscopic contraction, it is still difficult to integrate such networks efficiently into actual machines and generate forces large enough to actuate macroscale components,” commented Associate Professor Yuichi Hiratsuka from the Japan Advanced Institute of Science and Technology, Japan.

In collaboration with Associate Professor Takahiro Nitta from Gifu University and Professor Keisuke Morishima from Osaka University, Hiratsuka has made progress on this front.

In a study published in Nature Materials, the researchers described the construct of an actuator driven by two genetically modified biomolecular motors.

One significant characteristic of this method is that the actuator self-assembles from the basic proteins by simple light irradiation. Just seconds after light hits a given area, the adjoining motor proteins fuse with rail-like proteins called microtubules and assemble themselves into a hierarchical macroscopic structure that resembles muscle fibres.

Once formed around the target zone, these ‘artificial muscles’ contract and the collective force of the motor proteins is magnified from a molecular scale to a millimetre one.

With their experiments, the researchers highlighted that this technique could have applications in small-scale robotics, such as activating microscopic grippers to handle biological samples. As well as this, the technology could be used for joining separate components together or powering minimalistic robotic arms to make an insect-like crawling microrobot.

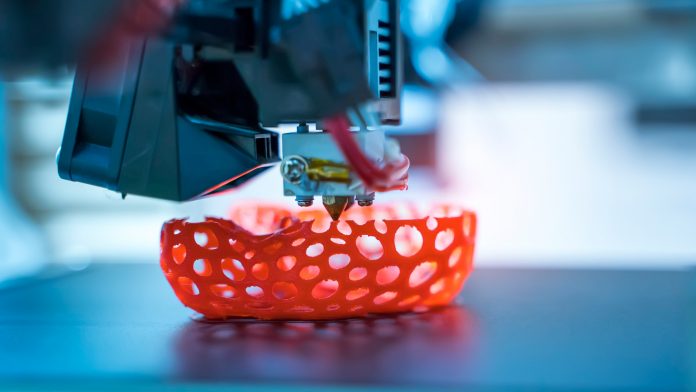

The method developed by the team is also compatible with 3D printing methods that utilise light. This means that microrobots with built in artificial muscles could be 3D printable, meaning they could be mass produced.

“In the future, our printable actuator could become the much-needed ‘actuator ink’ for the seamless 3D printing of entire robots. We believe that such a biomolecule-based ink can push forward the frontier of robotics by enabling the printing of complex bone and muscle components required for robots to further resemble living creatures,” added Hiratsuka.