Dr Venkataraman Thangadurai, Founder and Director of the Western Canada Battery Consortium, explains how a Canadian battery supply chain should be secured and discusses the future developments of next-generation battery technologies.

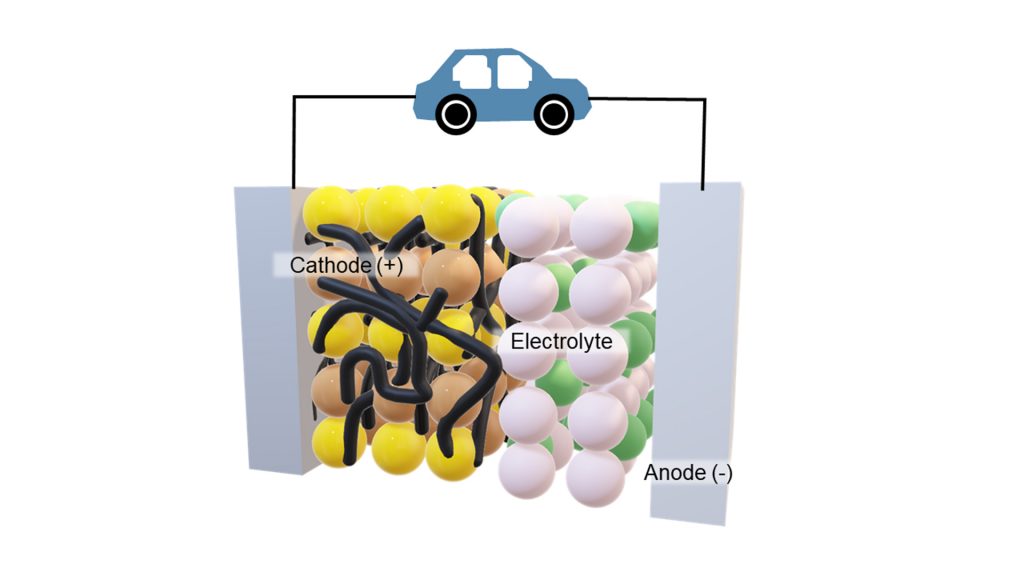

Driven mainly by the transition to electric vehicles (EVs), the lithium-ion battery (LIB) market is expected to exceed $129bn by 2027.1 Most of this market, around 80%, is currently retained by battery producers in Asia, with China controlling the majority of global battery material processing.2 This reliance on one country to supply battery materials makes the world vulnerable to supply chain issues. Both the European Union and the US realise the risk and are working on restructuring supply chains and procuring materials within their territories. In Canada, the government has committed to building Canadian battery and critical mineral supply chains through a “mines to mobility” approach.3

Canada’s push for a domestic battery supply chain

Canada is one of the only jurisdictions in the Western hemisphere with reserves of all the critical minerals required to produce advanced high-energy and high-power-density batteries for EVs and grid-scale applications. It has a large base of crucial battery raw materials, such as cobalt, graphite, lithium, nickel, copper, and manganese.4 Importantly, the country has the infrastructure and trade agreements needed to access the US and EU, two of the largest EV markets. Finally, the country has a skilled workforce and a cutting-edge battery research and development (R&D) ecosystem.

While Canada is poised to lead in developing sustainable battery materials and technology, its path forward is not without challenges. The country is still a long way from having a mature battery supply chain, despite being home to leading battery development centres and abundant raw materials. A recent report from Clean Energy Canada (CEC),5 a climate and clean energy programme within the Morris J Wosk Centre for Dialogue at Simon Fraser University, outlined several current challenges that Canada faces in creating a well-developed, domestic battery supply chain:

- Canada has minimal manufacturing capacity and lacks the processing capacity for battery-grade materials;

• Compared to other countries, Canada is slow in decision-making, causing administrative

processes, permitting, and funding allocations to have long lead times;

• Canada’s small market size makes it difficult to scale up domestic battery supply chains and to establish major battery manufacturing facilities;

• The country lacks significant investment in commercialisation and has a limited industrial policy;

• Canada cannot compete with China in terms of time and cost of producing battery goods and should look to other strengths, such as environmental, social, and governance standards and lifecycle greenhouse gas performances;

• Uncertainty around the technology, investment flows, and new players entering the market makes it difficult for one sector in the supply chain to scale up without similar actions occurring up and downstream; and

• The rapidly changing nature of the technology means that supply chains are challenged to keep up with the latest product ‘recipes’ and research priorities.

Addressing the challenges above requires coordinated action from policymakers, academic institutions, and supply chain participants. The same report by CEC also outlined Canada’s priority actions in the immediate term to establish itself as a player in the global battery industry. The recommended actions mainly involve focusing funding, co-operating with the US, promoting a clean and responsible battery brand, and forming task forces from the government and enterprises. One of the strategies also involves creating a battery centre that focuses on next-generation battery technologies, advanced manufacturing, and battery recycling.

Developing next-generation battery technologies in Western Canada

Organic electrolyte-based LIBs are the predominant battery technology in the market. However, other technologies, such as all-solid-state batteries, offer greater energy densities, faster charging, and safer operation than that of the current LIBs. These next-generation battery technologies will come to dominate in the next few decades, and testing and commercialisation of such technologies could help startups move the technology into mass production. Several groups in Canada are already studying the feasibility of such advanced battery technologies.

Leading battery R&D groups and institutions are located in Eastern Canada, but battery technology and supply chain opportunities are also abundant in the Western part of the country. Lithium is available in large quantities in brines in the Western provinces, and companies in Alberta and Saskatchewan are developing lithium extraction techniques from oilfield wastewater brines. Companies in Manitoba and British Columbia are developing zero-emission marine and land transportation. Initiatives at the University of Calgary, such as the Western Canada Battery Consortium (WCBC), and its core programme, the Battery Innovation Hub (BIH), align with Canada’s goal of strengthening the battery supply chain.

Founded in 2019 by world-renowned scholar Dr Venkataraman Thangadurai, the WCBC brings together Western Canada’s battery experts and industrial partners. The BIH will provide battery researchers and industry partners the facilities and experts to help them evaluate, certify, and qualify every step of battery development. The hub’s R&D activities will include next-generation solid-state electrolyte and electrode developments, raw material extraction, refinement, processing, characterisation, advanced electrode preparation, cell assembly and testing, and safety assessments. New battery materials and technologies at every step of the manufacturing process will be evaluated, qualified, and certified in this facility to generate intellectual property. Additionally, this initiative will train and employ researchers in Canada.

The BIH also aims to provide direct service to companies and other organisations in Canada, including producers, ensuring these companies are involved with and have strong access to ongoing battery research and innovation programmes worldwide. Its ultimate goal is to foster innovation and create intellectual property to help realise commercialisation.

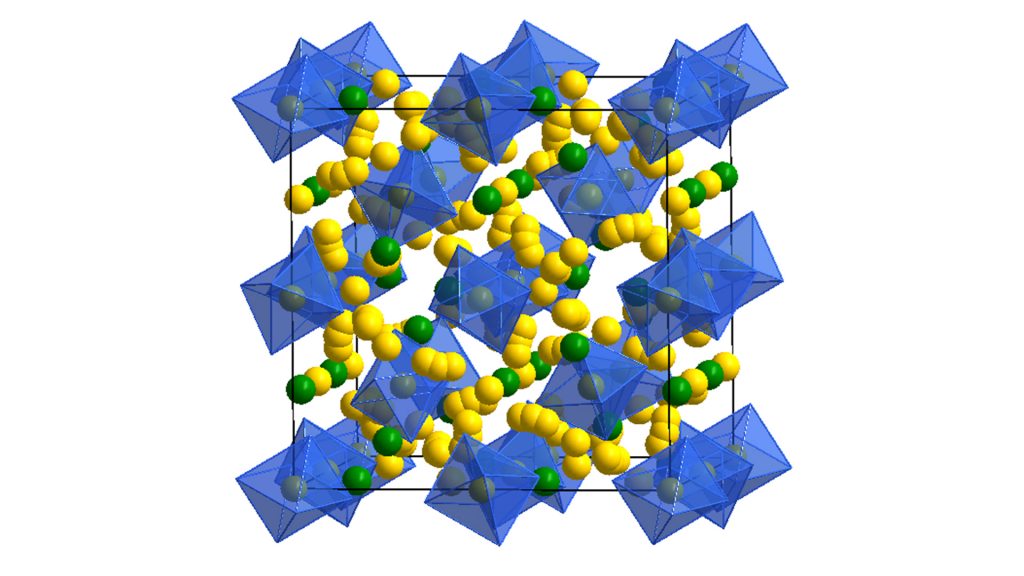

The consortium plans to develop safe, robust, and high-energy-density solid-state batteries with about five times the energy density as the current generation of LIBs (graphite anode, organic electrolyte, and a lithium nickel manganese cobalt oxide (NMC) cathode). The batteries from the consortium will be made from locally available lithium and sulphur resources. They will play a critical role in renewable energy integration with the electric grid and advanced battery-powered mobility and transport applications in Canada. Dr Thangadurai is leading the charge, having pioneered garnet-type ceramics (a silicate mineral structure) used in solid-state lithium batteries.6,7 His group continues to improve the technology of solid-state lithium and sodium batteries and advanced hybrid membranes for high-performance, safe batteries.

About Dr Venkataraman Thangadurai

Dr Thangadurai is an internationally acclaimed chemist who has made pivotal advances in solid-state electrochemistry, revolutionising solid-state energy storage and conversion technologies that can be integrated into zero carbon renewable energy systems. His research interests include designing, synthesising, and characterising novel solid-state electrolytes and electrodes for next-generation solid-state batteries and solid oxide fuel cells. His ground-breaking work on the development of Li-stuffed garnet solid electrolytes, which are safer, cleaner, more cost-efficient, and have increased power and energy density, enables the replacement of less safe commercial LIBs.

Dr Thangadurai has more than 220 peer-reviewed papers in journals. His work was cited over 15,700 times with an overall H-Index of 58 and was amongst the top 1% of Royal Society of Chemistry (RSC) journals in terms of citations in 2020. Dr Thangadurai is elected as a Fellow to the Royal Society of Chemistry, UK, a Fellow of International Association of Advanced Materials (IAAM), Sweden, and a Fellow of the Electrochemical Society, US. He received the Keith Laidler Award from the Canadian Chemical Society (CSC) for outstanding early career contributions to physical chemistry in Canada and the Award for Research Excellence in Materials Chemistry by the CSC.

Dr Thangadurai was appointed as a Scientist and Mentor at the Creative Destruction Lab-Rockies, a non-profit organisation that offers programming to enhance the success of scalable, seed-stage science- and technology-based companies. He has received a University of Calgary Peak Scholars Award, which is given to academics whose work in knowledge engagement, entrepreneurship, technology transfer, innovation, or collaborative research has resulted in a positive social or economic impact in the community.

References

- https://www.bloomberg.com/press-releases/2021-03-17/global-lithium-ion-battery-market-is-projected-to-exceed-129-billion-by-2027

- https://ca.finance.yahoo.com/news/asia-winning-war-ev-batteries-170000042.html

- https://www.canada.ca/content/dam/eccc/documents/pdf/climate-change/climate-plan/healthy_environment_healthy_economy_plan.pdf

- https://www.nrcan.gc.ca/science-data/science-research/earth-sciences/earth-sciences-resources/earth-sciences-federal-programs/canadian-mineral-production/17722#s3

- https://cleanenergycanada.org/report/turning-talk-into-action/

- https://ceramics.onlinelibrary.wiley.com/doi/10.1111/j.1151-2916.2003.tb03318.x

- https://onlinelibrary.wiley.com/doi/abs/10.1002/anie.200701144

Dr Venkataraman Thangadurai

Founder and Director

Western Canada Battery Consortium

Faculty of Science

University of Calgary

https://science.ucalgary.ca/

Please note, this article will also appear in the ninth edition of our quarterly publication.