Lithium-ion energy storage is one of the most promising technologies for the transition to clean energy. Springboarding straight from its success on the Sintbat project, the ECO2LIB consortium is upgrading its breakthroughs further.

In 2019, the Sintbat project was declared a success, as the consortium created a cheap, low-maintenance lithium-ion energy system that targets a lifetime of 20 years.

Towards the end of that same year, the consortium announced the ECO²LIB project. Designed to upgrade what they had already achieved in Sintbat, the project runs from 2020 to 2024 and was approved for funding from Horizon2020.

The importance of energy storage

Reducing costs is at the heart of the ECO²LIB project. The European Association for the Storage of Energy’s report estimates that by 2050, Europe alone will require 600GW of energy storage, and is currently running behind the deployment of sustainable energy producers.

Furthermore, solar energy is an example of meteorologically dependent energy production, meaning that there are peak periods and low periods of production. As such, energy storage will be required to take on the excessive energy produced and provide energy in the low periods when the meteorological methods are not producing enough.

Therefore, creating the most efficient and cost-effective energy storage possible is of the utmost importance in creating a world running on sustainable energy. In that sense, the total cost of ownership (€/kWh/cycle) is a relevant factor for rapid market penetration, i.e., technology transition. That is what the ECO²LIB project is for.

Taking innovation further

Our Ambition

The target was the introduction of advanced functional materials and sustainable processes into the commercially relevant 21700 cell format. To gradually improve towards scalable cell technology, an iterative approach via three cell generations was chosen. On that mission, the CoinPower® cell served as an optimal test vehicle to gather data on mass-production capability and cylindrical cell geometry while saving on raw material consumption.

There are several aspects to this project, comprising the development of the entire lifecycle of the energy storage cell, and they are designed to reduce cost further and increase efficiency. These include:

Increasing the energy density and cycle life

To fulfil the targeted parameters of 800 Wh/L and an increased life span of a stationary storage device beyond 15 years, the careful selection and tweaking of the materials, primarily silicon-based, in the construction of these cells ensures that the balance between cost and efficiency is maintained and optimised consistently.

Testing electrode and cell models

With the prior-selected materials, electrodes were constructed and tested, the best layout, system, and materials were determined, and any issues that needed addressing were identified. Finding the appropriate materials took a lot of work, and the materials used changed several times throughout the project.

Requirements specification, prototyping, and demonstration

The specific requirements for use cases have been identified, and prototypes have been developed based on those requirements. The consortium mainly focuses on home storage applications. Therefore, a new energy storage system has been developed and will

be exploited.

Recycling

An enhanced recycling process has been developed for the end of the cell’s lifecycle to reduce the costs and materials needed to produce new cells.

Recent developments

Currently, the project is near its finish point. Electrodes and electrolytes have successfully been produced and have achieved the required energy density. The battery module was also developed and optimised, and the basic recycling process was completed. Additionally, for the cathode, a water-born process has been successfully proven to be applicable to a small pilot line. The reduced potting time limited the transfer to large pilot facilities, though. Thus, some further optimisation is needed before mass production readiness is reached.

More recently, prototyping and modelling of several items, including the second generation of CoinPower®1254 cells, were completed. One of the main project goals was the successful introduction of silicon-heavy anodes on a pilot scale and the demonstration thereof in commercially relevant cell formats.

The ECO²LIB ambition was to source the best available Si-material on the market to fulfil set KPIs, which increase by their difficulty level per iteration cycle. In 2020, a µm-Si silicon (Gen.1-material) has been chosen to achieve a Si-dominant anode >50%Si. The target of 10% capacity increase and 70% cycle life capacity retention after 300 cycles was achieved in the first cell generation. It is notable that it was difficult to reach the project targets using the chosen µm-Si in the second cell generation, though. Luckily, at that time, advanced Si-material types became available on the market.

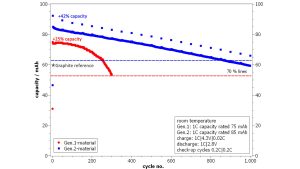

A supplier was found that was able to provide the necessary amount of silicon-carbon composite of the second generation, i.e., silicon encapsulated in a porous host structure to breathe but protected by a carbon layer from parasitic side reactions. The investigation has progressed into producing the slurry, electrodes and cells on a pilot scale, proofing a 42% capacity increase over the state-of-the-art. Based on this, a cycle life of 875 full cycles for 70% capacity retention was achieved. Moreover, at its 70% capacity fade, the cell still comprises higher energy than the commercial graphite reference in the same cell type. This is the first benchmark of such a material class under a publicly funded project, proving the case for silicon-heavy anodes.

Besides this achievement, it is notable that there are very limited sources worldwide for these Gen. 2-SiC-materials. Thus, it is relevant to continue the research on such high-performance Si anodes for the European market.

A second 21700 cell generation of this advanced SiC-material was also successfully created. Although there were higher failure rates than desired and the performance was slightly below the calculated target, the required improvements have been identified. Learning from this experience, the production of the third generation of this cell type is well on track to achieve the target of 800 Wh/L, utilising only standard NMC622 as cathode.

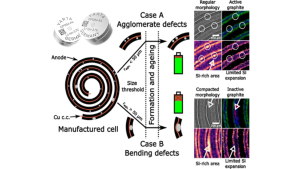

The development was made possible by the support of simulation and advanced analytical techniques. For example, synchrotron studies on cylindrical CoinPower® cells provided exciting insights into macroscale deformation mechanisms induced by Si-rich areas. A thorough slurry control dispersing the agglomeratedm<50µm remedies these defects. Results will very soon be published in Energy & Environmental Science.

Several aspects of the modules have been tested, including safety shutdowns, thermal characterisation, storage tests at various temperatures, lifespan tests, short circuit measurements, and drop tests. The module design is fully validated and is ready for project cell implementation. The launch of the new VARTAwall home storage system is expected in mid-2024.

Work is ongoing on factors such as electrolyte optimisation or the current collectors. The 3D copper current collectors require further development to boost their mechanical stability. Additional developments have been made in the recycling process, and all ECO²LIB-technologies have been assessed by a profound LCA and LCC analysis.

Conclusion

In conclusion, silicon-dominated anodes were the most crucial development, providing the qualities needed to successfully develop the cell into the efficient energy storage required. Having started with a more abundant Gen.1 Si-material, it was quickly found that this couldn’t quite fulfil the criteria. Instead, a non-EU material was applied to achieve much better results. As such, further research into batteries and their materials is critical and will lead the EU forward in this sector.

In summary, the ECO²LIB project is well underway and developing lithium-ion cells that excel at their role: storing sustainable energy, directing it to where it needs to go, and preventing any intermittency issues. The results are getting better every day, and it will be exciting to see the final achievements at the end of the project.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 875514.

Please note, this article will also appear in the 18th edition of our quarterly publication.