Researchers have found that C02 can be converted into chemicals or fuels electrochemically using stable copper catalysts.

CO2 (carbon dioxide) can be converted electrochemically into starting materials for industry. However, , finding catalysts that are stable over a long period of time has posed challenges.

Now, a team of researchers at Ruhr-Universität Bochum and the University of Duisburg-Essen have developed a new catalyst for the conversion of carbon dioxide.

The team’s research is outlined in the journal Angewandte Chemie.

CO2 can be converted into larger carbon compounds and then used as base chemicals for industry or as fuels.

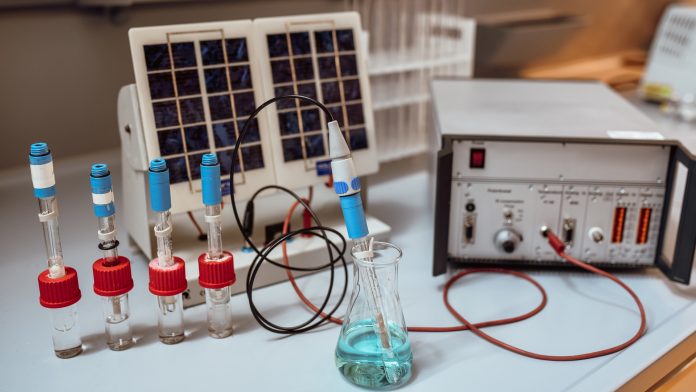

Researchers are hoping to convert CO2 electrochemically with the aid of renewable energies. This could be used to create useful products and would also act as storage for the renewable energies.

Copper has already proven to be a promising catalyst in previous studies, but it must be in the form of a partially positively charged ion, which poses significant difficulties.

Under typical reaction conditions, copper is quickly converted from its positively charged form to its neutral state, which is unfavourable for the formation of products with more than two carbon atoms and thus deactivates the catalyst.

The team optimised pre-existing copper catalyst by modifying it with boron. They tested various copper-boron ratios and established the most optimal composition to favour the formation of compounds with more than two carbon atoms.

Their research indicated that the boron-copper catalyst can be operated at current densities that would be required on an industrial scale.

They implemented the system in the form of a gas diffusion electrode in which a solid catalyst catalyses the electrochemical reaction between the liquid and gaseous phases. It is vital that enough CO2 dissolves in the boundary between the gas and liquid phases. The team were able to achieve this by using a special binder.

Another challenge posed to the team was being able to keep the catalyst system stable for a long period of time. In order to solve this, they integrated a “sacrificial anode” made of zinc into the system. As zinc is a less noble metal than copper, it is corroded first, sparing the copper.

Wolfgang Schuhmann, of the Bochum Center for Electrochemistry, who co-led the team, explained: “The combination of a selective and active catalyst material in a gas diffusion electrode and the addition of the stabilising zinc is an important step towards the use of CO2 for the synthesis of base chemicals.”