A team of researchers at KAIST has developed a groundbreaking technology that enhances the diagnosis and monitoring of electric vehicle (EV) batteries.

Using a refined approach based on electrochemical impedance spectroscopy (EIS), this new system promises to significantly boost the long-term stability and efficiency of EV batteries, marking a major leap forward in sustainable transportation.

High-precision battery diagnostics with low current

Accurately assessing the health and efficiency of EV batteries is crucial for their safe and long-term use.

Traditional methods, while effective, often require high currents that can cause electrical stress and lead to potential failures or safety risks.

The innovative technology developed by KAIST researchers addresses this issue by utilising electrochemical impedance spectroscopy with much smaller current disturbances, minimising the risk of damage and overheating during the diagnostic process.

This advanced EIS system, developed by Professors Kyeongha Kwon and Sang-Gug Lee from KAIST’s School of Electrical Engineering, operates with a current disturbance as low as 10 milliamperes (mA).

This ensures high-precision measurements while preventing the thermal effects and safety concerns associated with traditional, higher-current systems.

This is expected to vastly improve the safety, reliability, and overall performance of high-capacity batteries used in electric vehicles.

What is electrochemical impedance spectroscopy?

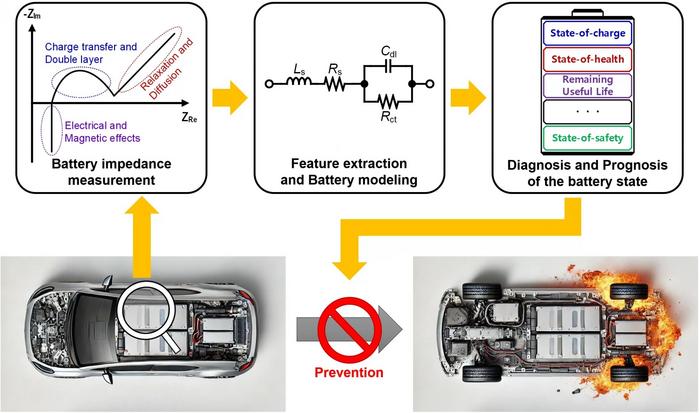

Electrochemical impedance spectroscopy is a powerful diagnostic tool used to measure the impedance, or resistance, within a battery.

This data can provide valuable insights into the state of charge (SOC) and state of health (SOH) of the battery, which are key factors in determining its efficiency, lifespan, and safety.

By detecting changes in impedance, EIS can also identify thermal characteristics, physical and chemical changes, and even predict potential failures before they occur.

This breakthrough technology allows for real-time, in-depth analysis of the electrochemical properties of EV batteries under various operating conditions, such as different temperatures and charge levels.

A compact, cost-effective solution

One of the most significant advantages of the newly developed EIS system is its cost-effectiveness. Traditional EIS equipment is often expensive, bulky, and difficult to integrate into electric vehicles.

KAIST’s new system, however, minimises the need for complex and costly components, making it easier to implement directly into EV systems without sacrificing diagnostic accuracy.

Professor Kwon added: “This system can be easily integrated into the battery management system (BMS) of electric vehicles and has demonstrated high measurement accuracy while significantly reducing the cost and complexity compared to traditional high-current EIS methods.

“It can contribute to battery diagnosis and performance improvements not only for electric vehicles but also for energy storage systems (ESS).”

The future of EV battery management

This development by KAIST represents a major advancement in EV technology. By utilising low-current electrochemical impedance spectroscopy, the research team has created a solution that not only improves battery diagnostics but also ensures greater safety and longevity of EV batteries.