ELEMISSION’s ECORE core scanner offers new opportunities by delivering real-time quantitative automated mineralogy using LA-AES (LIBS).

Critical minerals are essential for the global transition towards a greener future. They are required to develop many new technologies, including low-greenhouse gas energy sources, and are the backbone of the current electric vehicle revolution. The Government of Canada has identified 31 critical minerals and metals that are instrumental for sustainable economic prosperity and growth within Canada and its trading partners.

Many of these minerals, including lithium (Li), aluminium (Al), cobalt (Co), copper (Cu), nickel (Ni), zinc (Zn), and rare earth elements (REEs), are currently mined and actively being explored nationwide. Demand for critical minerals is rapidly increasing around the world. Therefore, the optimisation of their exploration and processing is crucial for propelling society toward a more sustainable and environmentally conscious future.

Conventional core scanning technologies

In an attempt to optimise the exploration and production of critical minerals, many exploration and mining companies have turned to the digitisation of drill cores. This generally permits faster logging and interpretation when compared to traditional methods, while facilitating geological modelling and the archival of information.

This has resulted in a rise in the popularity of core scanners. In general, they are meant to streamline and maximise efficiency when core logging while providing textural and mineralogical data that a core logging geologist could otherwise miss. The most commonly used core scanners rely on infrared hyperspectral imaging (IR-HSI) and X-ray fluorescence (XRF).

IR-HSI drill core scanners are able to provide large amounts of textural and mineralogical information rapidly and at a relatively affordable price, while XRF scanners are able to provide chemical composition and elemental information.

In the case of HSI, metal oxides and sulphide minerals are not spectrally active and therefore cannot be identified. This is troublesome for the analysis of critical metals, as they are often hosted in sulphide or oxide minerals. XRF technology cannot detect light elements (Z<13). Mg (Z = 12) and Na (Z = 11) can be detected but require longer dwell times that are not conducive to rapid core scanning.

Furthermore, XRF is not capable of identifying mineralogy, only elemental information. Because of this, it is impossible to distinguish between minerals that have similar compositions, and it is difficult to extract important elemental deportment information crucial for fully understanding a deposit.

The limitations of these methods can result in the loss of critical information that can greatly impact decision-making and thus require additional techniques to complement and enhance their information, which adds more time to the overall analysis. The shortfalls of these methods, combined with the growing demand for critical minerals, create room for an emerging technology that can provide rapid and accurate results without these same restrictions.

ECORE scanner

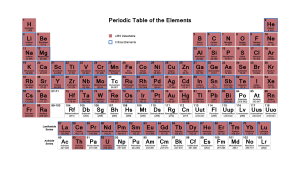

ECORE, manufactured by ELEMISSION Inc. (Fig. 1), is a fully automated, high-speed laser-induced breakdown spectroscopy (LIBS) commercial drill core scanner that is capable of detecting almost every element on the periodic table (Fig. 2), which includes every element involved in Canada’s list of critical minerals.

ECORE is able to provide rapid (less than five minutes per core box, more than 300m per day) chemical and mineralogical information, along with invaluable textural information at high resolution. The following case studies demonstrate the application of ECORE to the analysis of critical minerals while simultaneously highlighting the importance of having access to mineralogical and full chemical information.

Case study one: Lithium pegmatite

Over 120 mineral species contain lithium as an essential constituent, and 44% of them can be found within lithium-caesium-tantalum pegmatites, the most important economic source of lithium globally. Lithium reserves in pegmatites mostly occur in the form of lithium-silicate minerals. These most commonly include spodumene (LiAlSi2O6), petalite (LiAlSi4O10), and lepidolite (KLi2Al(Al,Si)3O10(F,OH)2.

Differentiating between different lithium-bearing minerals is extremely important in the context of understanding the economic potential of a deposit, especially given the great diversity of possible lithium species.

The extraction and processing methods can vary depending on the main host mineral since mining and processing procedures need to be adjusted based on the physical properties of the specific mineral. As a result, understanding the contribution of lithium from each mineral present in the deposit is crucial for an accurate estimation of mining and processing costs.

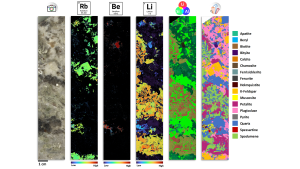

ECORE is able to easily differentiate between lithium-bearing minerals, even those that vary only slightly in composition, such as spodumene and petalite.

This is demonstrated in Fig. 3, where, using RGB mapping, spodumene and petalite are easily distinguished from one another within the same core sample. Feature mapping like this has proven to be very useful not only for discriminating between mineral phases but also for highlighting compositional variations within the same mineral.

Mono-elemental mapping provides the advantage of being able to understand the context in which mineralisation is hosted, along with providing important elemental deportment information. This information can then be represented in the form of a mineralogical map using ELEMISSION’s proprietary Smart Automated Mineralogy (SAM) learning algorithm.

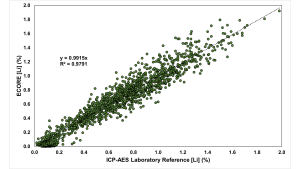

Using ECORE technology, predicted and true chemical assays are able to be provided in real-time. Fig. 4 shows ECORE chemical assays taken at one-metre intervals over 1500m of drill core from a lithium pegmatite deposit compared to assays obtained by a standard laboratory method (ICP-AES, four acids). The R² value (0.98) and the slope of the curve (0.99) reveal a very strong correlation between these two methods and demonstrate that the ECORE core scanner is equally effective and reliable when compared to traditional laboratory methods.

Access to instantaneous quantitative chemical data that can easily be generated as a function of depth at intervals of the user’s choice is invaluable, as it facilitates rapid decision-making and eliminates the week- or month-long delay that is typically associated with waiting for traditional lab assay results.

Case study two: Porphyry copper

Understanding the mineralogy of a deposit is not only important for optimising production and planning for future extraction but also for understanding controls on mineralisation to facilitate exploration. In porphyry copper deposits, hydrothermal fluids concentrate metallic elements and produce extensive alteration haloes around an intrusion.

This results in mineral zonations that form approximately concentric patterns whose changes in mineralogy can serve as a vector towards mineralised centres.

In practice, these patterns are often difficult to recognise by eye due to commonly occurring later-stage overprinting and alteration events and therefore require the expertise of a skilled geologist aided by petrographic thin section analysis and the use of more complex, expensive, and time-consuming instruments such as electron probe micro-analysers (EPMA) or X-ray diffractometers (XRD) to comprehend.

With ELEMISSION’s core scanner, automated and precise mineralogical maps can be created to consistently recognise lithological units and their distinctive mineralogy. Sulphide and oxide mineral species can easily be identified and differentiated, which allows for simple visualisation of mineralisation behaviour within the core.

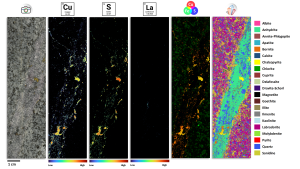

Fig. 5 shows a high-resolution SAM image of a section of core from the ore zone of a porphyry copper deposit. The image clearly shows two different copper-bearing sulphide minerals (bornite and chalcopyrite) hosted within an anhydrite-quartz vein. Within both the vein and the host rock, metal oxide (magnetite, delafossite, ilmenite, and cuprite) and oxyhydroxide (goethite) species can be distinguished from each other.

Additionally, elements that occur in trace amounts throughout the core (e.g., lanthanum) can also be identified while preserving spatial information, so associations between minerals and these elements can be made.

Conclusion

ECORE revolutionises the extraction and discovery of critical minerals by providing large amounts of information rapidly, thereby allowing for faster and more precise interpretations to be made during the exploration, extraction, and production stages. Within minutes, users can access mono-elemental and RGB maps, automated mineralogical images, and full chemical assays.

The capability of ECORE to detect almost any element on the periodic table means that there are no limitations in the types of core that can be analysed and also minimises the amount of additional analytical methods required for geologists to make their interpretations.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.