Introducing Margosa Graphite Limited and the Ridee Ganga Project, an integrated vein graphite mine/value add proposal that will ultimately supply high purity vein graphite materials for energy storage and other high-end industrial applications.

Margosa Graphite Limited is focussed on becoming a world leading producer of high-quality vein graphite and developing a significant value added materials business in Sri Lanka, built on the near term development of the Ridee Ganga Vein Graphite Project (RGVGP), located 45km southeast of Colombo, and the future advancement of the Company’s other Tier 1 exploration opportunities. Utilising smart and innovative technologies, Margosa aims to deliver a high margin, low cost/risk underground mine and an advanced materials processing facility within a mining friendly regime.

The RGVGP represents the highest grade JORC compliant graphite deposit in the world. In March 2019, the Company reported an inaugural Mineral Resource Estimate (MRE) of 400,340 tonnes grading 79.1% Total Graphite Content (TGC) at the RGVGP to its shareholders. In April 2020, following further detailed diamond drilling, an upgraded MRE of 1.73 million tonnes grading 76.3%TGC was reported, representing a 316% increase in contained graphite. This resource remains open along strike and at depth.

A Pre-Feasibility Study (PFS) completed in November 2020 supports Margosa’s early objective of becoming the first producer to provide a consistent and secure supply of unique and superior high-grade crystalline vein graphite to the global market. Building the market and production profile, for the first four years the Company aims to produce in excess of 40,000 tonnes of high purity vein product per annum over an initial 15 year period. The PFS delivered compelling valuation metrics with a pre-tax NPV10 of US$258m and IRR of 70%.

About vein graphite

Sri Lanka is the only country in the world where high purity crystalline vein graphite is found in commercial quantities.

Vein graphite, recognised as a premium quality and niche material, is formed from high temperature hydrothermal fluids and has graphitic contents as high as 99% TGC in its natural state. Vein graphite is isotropic and has the highest degree of crystal perfection of all natural graphite forms. As a result, it delivers enhanced thermal and electrical conductivity, has a very high degree of cohesive integrity, and provides superior performance for many products and applications. Vein graphite’s evolution, needle/platy morphology, superior properties, and ultra-high purity, make it the only true competitor to the intensely processed, environmentally unfriendly, and highly priced synthetic graphite.

Development outlook

Despite the COVID-19 pandemic’s effects on industry globally, the Company has recently received approval from the Sri Lankan government for the development of a 100 metre exploration shaft within the RGVGP, which will deliver 100 tonnes of bulk vein material for advanced offtake marketing and metallurgical purposes, provide valuable geotechnical data, and deliver future ventilation, egress, and service supply for the main decline development. Roughly 80% of this material will be utilised in near term qualification testing, with the remainder directed to potential global commercial customers and partners in Europe, East Asia, USA, and Australia.

Meanwhile, an Industrial Mining Licence application, including all essential environmental, community, and social impact reports was submitted to the Geological Survey and Mines Bureau in 2020 and is due for approval in 2021.

The Company’s underground mining has been planned as a combination of bulk and selective mining techniques to deliver a significant, consistent, and secure production profile. A decline will present as the primary mine access for an operation with a very small environmental footprint. In line with the aim of an ethical and aesthetically responsible model, all waste and tailings from mining and processing will either be returned underground for use as fill, used as aggregate for concrete, or made available for civil purposes. Mine development will be undertaken with 1,000 volt electric drill machines, loaders, and low profile 20 tonne off-highway trucks.

Initial metallurgical test work has highlighted that a superior high purity product can be produced via a simple and conventional beneficiation process flowsheet. Currently, further inhouse studies are being undertaken which the Company believes will further streamline and refine the final process schedule.

In terms of the RGVGP timeline, Margosa remains on track to begin:

- Primary mine access (decline) – in the first half of 2022;

- Process plant procurement and construction; and

- Mine production – in early 2023.

The RGVGP is development ready with over $5m of mining and construction equipment already purchased and onsite or in the process of being shipped.

A final phase of diamond drilling is currently being carried out at the RGVP to upgrade the mining inventory and provide further critical engineering, geotechnical, and metallurgical information.

Innovation and value addition

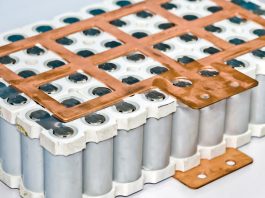

Margosa is highly supportive of Sri Lanka’s enthusiasm to not only become a significant player in the global graphite supply chain, but to develop, innovate, and produce its own high-quality value add products, particularly in the ever-growing lithium-ion battery (LIB) and energy storage markets.

In line with this focus on energy storage and industrial opportunities, extensive specialist analytical and engineering tests have been budgeted and are due to commence in 2021. The areas to be assessed in detail include:

- Chemical and physical characterisation of the final beneficiated product;

- Purification testing;

- Micronisation and spheroidisation performance and characterisation;

- Electrochemical characterisation of the purified product (this will include cyclic voltammetry that measures kinetics and hysteresis of the charge/discharge cycle, specific capacity, and cycling performance); and

- Expandability classification testing for premium expandable precursor products.

Dependant on the results of this test work, a scoping level study is being planned to look at the viability of developing a staged downstream graphite purification and advanced materials processing facility in Sri Lanka.

The Company believes it will be able to produce a wide range of specialty graphite materials that will support the recent and future upsurge in demand for energy storage applications (particularly electromobility), but also increasing demand from a range of high technology and industrial applications, such as specialty conductivity-enhancement materials. In some cases, the strategy includes the displacement of synthetic graphite.

With respect to the battery anode market, the growth in LIBs is just the beginning and represents a long term, government-supported, structural opportunity for the purified natural graphite market.

“Demand from the lithium-ion market alone is expected to rise from nearly 200,000 tonnes per year in a 700,000 to 800,000 tonne current market to nearly three million tonnes a year in a four million tonne market by 2030,” George Miller, from Benchmark Mineral Intelligence (2020), said.

Vein and flake graphite are the only natural forms that can be used as raw material for anodes in LIBs due to their high degree of graphitisation and crystal characteristics. To date, the limited quantities of vein graphite produced in Sri Lanka has restricted its use in LIBs.

A significant issue for flake graphite and its LIB application is that it is an anisotropic material. This morphology adversely affects the uniform distribution of the particles on any current collector. Because of this orientation issue, it becomes more difficult for Li ions to intercalate into the graphite structure since the intercalation of Li ions occurs through edge-plane surfaces. Subsequently, flake graphite demonstrates poor rate capacity.1 As a result, upgrading processes are necessary to provide high purity flake graphite and to solve the problem of low-rate capacity.

Conversely, high crystallinity vein graphite is isotropic, has a higher tap density, and as such is likely to be a much more desirable material for LIB application. In recent performance studies conducted at the Centre of Ionics in Malaysia2 a developed natural vein graphite material displayed characteristics such as enhanced electrical conductivity, high purity, modified surface qualities, and high crystallinity, making it attractive for anode application in LIBs. Cyclic voltammograms and charge-discharge studies confirmed a high and stable reversible capacity of 378 mA h g-1, which is significantly higher than the theoretical capacity (372 mA h g-1) of LiC6. A Columbic efficiency over 99.9%, strong structural stability, low internal resistance, and unperturbed Li ion diffusion supports vein graphite’s exceptional qualities and suitability for development as a low-cost alternative anode material.

Synthetic graphite manufactured under high temperatures from a petroleum coke precursor and engineered to exacting specifications is also used in LIBs. Whilst synthetic graphite offers predictability and potentially higher life cycles in batteries, it is costly, time and energy intensive, and its production leads to severe environmental implications with the carbon, sulphur, nitrogen, and particulate emissions following its fossil fuel refining. Sri Lankan vein graphite has been formed under similar but natural pyrolytic conditions. In a recent crystallographic study presented by the Sri Lankan Institute of Nanotechnology3 it was reported that vein graphite has a near identical spectroscopic fingerprint to synthetic graphite.

With its unique and superior properties, high natural purity, low cost, and carbon footprint, Margosa believes its RGVGP offers the best attributes and advantages of both natural flake and synthetic graphite in one product. The Company firmly believes vein graphite represents the best quality and most effective and efficient material not only for the battery anode and energy storage industries, but many other high-end products and applications. The Company’s near-term objective is to demonstrate this as well as building a robust new business proposition in a supportive and mining friendly country.

Exploration upside

Margosa has been a pioneer in the field of exploration since it first commenced work in Sri Lanka in 2012. The Company was the first to successfully use modern ground and downhole electromagnetic (EM) survey methods, which led to the discovery of the Ridee Ganga deposit.

In 2017, Margosa carried out a 1,700-line km high resolution helicopter-borne time domain EM (HDTEM) survey focused on defining the next generation of graphite deposits in Sri Lanka. Six Company controlled project areas all within the main graphite bearing districts and less than 100km from Colombo were surveyed. Perth based Southern Geoscience Consultants Pty Ltd were commissioned to model the data, with a view of generating ranked exploration targets for each of the areas flown. Results from this ground-breaking work along with mapping and ground-truthing have been used to plan reconnaissance drill programs and further detailed ground geophysical surveys.

In 2021, the Company, with the assistance of its strategic geophysical partners, will commence beta testing a new and innovative portable ground EM system which it hopes will provide rapid and accurate identification of the numerous graphite bodies delineated by the earlier HDTEM work. Reconnaissance diamond drilling utilising Margosa’s owner-operated drill equipment will follow.

The future

The forecast growth in the battery graphite demand over the next decade is enormous, with unprecedented investment underway in Asia, North America, and Europe to establish gigafactories to supply LIBs for electric vehicles, energy storage, and electronic products. Global battery demand is expected to grow by a factor of 19 over the decade with electric vehicles forecast to comprise over 30% of the vehicles sold per annum by 2030 By 2050, almost all vehicles sold are predicted to be electric.4

These projections along with the strong valuations from the Company’s recent feasibility studies supports our belief in the Ridee Ganga Vein Graphite Project and our aim to develop a robust sustainable and integrated graphite business with a traceable supply chain from ethical sources.

Additionally, the capability to build a much larger resource base at RGVGP and within the Company’s other unexplored licences in Sri Lanka, is exceptional and compelling. Supported by modern and innovative exploration methods, a strong technical team, and our owner-operated equipment and crew, Margosa is in the enviable and privileged position to potentially build a much larger production profile to fill possible customer requirements over the longer term.

Margosa has a very promising future and looks forward to updating its partners, stakeholders, and current and future shareholders as we announce further significant milestones and potentially progress to a public listing in the next 12 months.

References

- A. D Allah et al. ‘Purification, application and current market trend of natural graphite: A review’. International Journal of Mining Science and Technology 29 (2019) 671-689

2. H. P. T. Hewathilake et al. ‘Performance of developed natural vein graphite as an anode material of rechargeable lithium-ion batteries’. Ionics 23 (2017) 1417-1422

3. The SLINTEC Initiatives.

4. ‘A Vision for a Sustainable Battery Value Chain in 2030’ – World Economic Forum – Insight Report, September 2019

Please note, this article will also appear in the seventh edition of our quarterly publication.