Andrea Augieri, CEO and Co-Founder of Suprema, explains why the company is well positioned to accelerate fusion commercialisation with the production of high-temperature superconductor tapes.

Founded by a group of highly experienced physicists, innovative Italian start-up Suprema is already making waves in the clean energy sector with its mission to design and produce high-temperature superconductor (HTS) tapes.

The company is a spin-off from ENEA (National Agency for New Technologies, Energy and Sustainable Economic Development) – the Italian public institution for energy and the environment. Now, the four ENEA researchers behind the company – Andrea Augieri, Fabio Fabbri, Francesco Rizzo, and Giuseppe Celentano – are pooling their expertise and resources to build Europe’s largest plant for the production of superconducting tape at high critical temperature.

The Innovation Platform spoke to CEO and Co-Founder Andrea Augieri to find out more about the company, its goals, and the vast potential of HTS tapes within a variety of applications.

Can you explain more about Suprema as a company and your products?

Suprema was founded in July 2024 with the goal of realising a factory for high-temperature superconductor tapes. HTS tapes are a critical component of many applications in the energy sector, from nuclear fusion reactors to the electric grid.

The co-founders all have a background as physicists, having previously worked in the fusion department at ENEA. We have been working on HTS tape technology for over 20 years, to optimise the technology for fusion applications and to develop it for other applications.

What makes your HTS tapes different?

We realised that there’s currently a huge demand for this product, predominantly driven by the push for fusion energy. We also concluded that there are few people in the world able to undertake all the processes required to manufacture an HTS tape.

Since we have more than 20 years in R&D on this technology, we have many ideas on how to improve the product, as well as its manufacturing processes. This will help to lower the cost of an HTS tape, as one of the main issues with this product currently is the high cost.

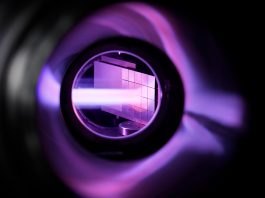

We will be using our innovative and proprietary solution to improve its performance. The superconducting layer has to be nano-engineered to allow this product to perform better. Once we are on the market as a reliable player, we can apply all our longstanding experience in R&D to further improve the HTS tape.

What role can the HTS tapes play in the journey to fusion commercialisation and a more sustainable future?

HTS tapes are the enabling technology for fusion. However, previous projects have so far only used the old class of superconductors – known as low-temperature superconductors (LTS). The issue is that superconducting materials are required to generate high magnetic field, which is needed to confine the plasma to achieve the fusion reaction. The power of a fusion reactor scales with the fourth power of the magnetic field intensity.

HTS can achieve higher fields than the LTS, while also enabling higher operative temperatures, thereby allowing for much more compact fusion reactors and ultimately reducing the cost of electricity production by fusion. Having compact but still very powerful reactors is the only way that commercialising fusion energy can be made possible. This is why HTS tapes are the enabling technology, as you can only have compact fusion reactors with HTS tapes.

How are you collaborating with other organisations to advance and distribute the HTS technology?

We are in a very good position, having previously worked in a research capacity with most companies aiming to use the HTS. Through helping them to develop products, we have built up longstanding relationships with these companies and we are in contact with most fusion startups in the world, both in Europe and the US. These startups are really interested in Suprema because HTS tapes are the key enabling technology for fusion reactors.

We are also collaborating with companies in other areas, such as mobility, biomedical, science experiments, and the electric grid. In addition, we are part of European associations, including the European Fusion Association (EFA) and CurrENT, promoting HTS tapes as a reliable and powerful solution to help improve existing technologies for a greener economy.

What are your focuses for the near future and beyond?

We are about to commence the build of the factory that will produce the HTS tapes, and we are aiming to have a fully operative production line by the end of 2027.

We are convinced that, once we are in full production, the market will be able to take all our production. We are also already planning a scale-up of our production. The first production line will not be a point of arrival, but a starting point – from there, we will scale up by opening many other production lines.

Please note, this article will also appear in the 22nd edition of our quarterly publication.