Using a new LIBS system, the measurement of salts within nuclear power systems can be easier than ever. Professor Phonigikaroon of Virginia Commonwealth University discusses this new system and the potential it holds.

Imagine being able to peer into the system of an advanced nuclear reactor design and monitor the composition of the molten salt that fuels it in real-time. This isn’t science fiction – it’s a capability that laser-induced breakdown spectroscopy (LIBS) could bring to the nuclear industry.

LIBS is a powerful analytical technique. It uses a high-powered laser to blast a sample into a plasma, releasing a flash of light that acts as a fingerprint and reveals which elements are present. Scientists have already explored LIBS to analyse nuclear materials in molten salt. Still, there’s a catch: most of these studies required removing the salt from the reactor, a time-consuming process with a risk of contamination.

A few scientists and engineers have attempted to use LIBS to analyse molten salt directly. They’ve pointed their lasers at the churning surface of the salt, but this approach has its downsides. The laser can create splashes, introducing errors and damaging equipment.

There’s a better way. What if you could create an aerosol from the molten salt and then analyse that instead? This approach has shown promise, but it needs refinement. That’s where the team at Virginia Commonwealth University (VCU) comes in.

VCU and the LIBS system

The VCU researchers are on a mission to perfect the molten salt aerosol-LIBS setup. They’re focusing on measuring the concentration of cerium, an element that mimics the behaviour of plutonium and can be safely handled. By optimising their technique for cerium, they can create a blueprint for monitoring other nuclear materials.

The potential impact is huge. Aerosol-LIBS could revolutionise nuclear engineering, replacing slow and dangerous sample extraction with real-time monitoring. It could make pyroprocessing technology and molten salt reactors both safer and more efficient. Opening up research opportunities to more students could also help train the next generation of nuclear scientists. The VCU team’s work is just the beginning – as they refine their technique and share their findings, they’ll bring the nuclear industry one step closer to a future where reactors run cleaner, safer, and smarter. And it’s all thanks to the power of a laser and the insight of LIBS.

Experimental scheme

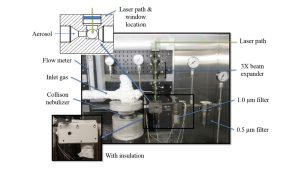

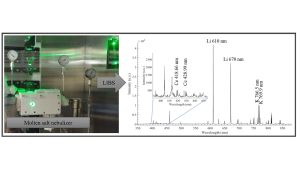

This study utilised a modified molten salt aerosol-Laser Induced Breakdown Spectroscopy (LIBS) system, building upon the design of Williams and Phongikaroon.1,2 Key modifications included a redesigned sampling chamber with a sudden expansion nozzle to minimise mixing and laser light obstruction (see Fig. 1). The chamber featured three 19mm sapphire windows for improved optical access and ease of cleaning. Dual filtration (1.0µm and 0.5µm) ensured complete aerosol removal with minimal pressure drop. The system was insulated for easy access and operated within an argon atmosphere glove box. A Nd:YAG laser (532nm, 50±5mJ) was used for excitation, with a 3X beam expander added to the optical path (see Fig. 2). Emissions were collected via a 75mm lens, redirected by an elliptical mirror, and focused onto a 50µm fibre leading to an Andor Mechelle 5000 spectrometer with ICCD detection.

Pressures were monitored at five system locations. The nebuliser inlet to sampling chamber differential was maintained at 12psi for consistent aerosol generation. System temperatures were controlled, with the sampling chamber operated below 500°C to prevent window damage.

Experiments employed LiCl-KCl eutectic salt with CeCl3 as a surrogate, with concentrations spanning 0.1-5wt%. Salts were prepared in an inert glovebox, dried, melted, and homogenised. The nebuliser design required the salt ingot to be broken into smaller pieces for loading.

Initial experiments optimised the LIBS gate delay (100ns to 25µs). Calibration curves were then generated by averaging 300 shots per repetition, with seven repetitions per sample. Additional data was collected after five hours of operation for one sample. Post-experiment, deposited salt was recovered, and all components were cleaned. Material balance was tracked, though some loss was unavoidable due to thin film deposition on stainless steel components. Salt samples from various system locations were dissolved in nitric acid and diluted for ICP-MS analysis using an Agilent 7900 instrument.

Outcomes and achievements

Univariate and multivariate calibration models were developed and successfully tested. The best univariate calibration curve was generated using the Ce 446.02nm line and yielded a limit of detection (LOD) of 0.013wt% Ce with a root mean squared error of cross-validation (RMSECV) – leave-one-out cross-validation – of 0.059wt% Ce. For the multivariate calibration approach, a partial least squares (PLS) model was generated using seven latent variables. The RMSECV for the PLS model was determined to be 0.052wt% Ce using Venetian blinds cross-validation with ten splits in the data and with 10% being left out per split. The LOD determined in this work are in the lower range for Ce – as found in the literature. This work has demonstrated that the molten salt aerosol-LIBS system is capable of quantitative measurements in real-time (see Fig. 3).

References

- A. N. Williams, S. Phongikaroon. 2017 “Laser-Induced Breakdown Spectroscopy (LIBS) in a Novel Molten Salt Aerosol System,” Applied Spectroscopy, 71, 744-749.

- A. N. Williams, S. Phongikaroon. 2018 “Laser-Induced Breakdown Spectroscopy (LIBS) Measurement of Uranium in Molten Salt,” Applied Spectroscopy, 72, 1029-1039.