Researchers at Kyoto University have found an environmentally friendlier solar cell production method that utilises PEDOT:PSS/silicon heterojunction solar cells.

Non-renewable energy resources, such as coal, oil, and natural gas, have overshadowed current optoelectronic devices. It is thought that this could be partly due to ongoing challenges in solar cell production.

Now, researchers at Kyoto University may have found an environmentally friendlier solution with a hybrid solar panel made of organic-inorganic material. PEDOT:PSS/silicon heterojunction solar cells, which also have an enhanced performance, could potentially ease the production process compared to conventional silicon-only solar cells.

The paper, ‘An all ambient, room temperature–processed solar cell from a bare silicon wafer,’ is published in PNAS Nexus.

The importance of solar energy

With many countries pledging to reduce their carbon dioxide emissions over the coming decades, securing renewable energy technologies is critical.

Solar energy is a source of renewable energy that can be used to power homes, businesses, and communities. It is considered to be one of the most cost-effective ways to generate electricity.

However, existing methods of solar cell production are providing barriers to widespread implementation.

Challenges to solar cell production

Currently, manufacturing solar cells is an energy-intensive process that requires finite materials. Producing photovoltaic cells is not carbon-free, as they are made from crystalline silicon that must be purified using chemicals and extreme heat.

Solar cell production is centralised in China, with nearly half of the world’s solar-grade polysilicon market coming from the Xinjiang region. Here, the cells are processed using coal power – considered to be the dirtiest of all fossil fuels. Because of this, scientists are looking to find alternatives to these solar cells.

Lead author of the study, Katsuaki Tanabe, emphasised the importance of solar cell alternatives for the green energy transition, and explained: “We wanted to avoid manufacturing solar cells in vacuums and high-temperature processes, which require large and expensive equipment and a great amount of time.”

The team used ambient temperature and pressure conditions

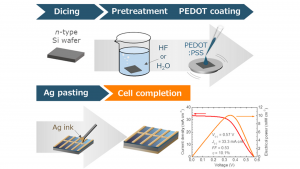

The team set out to fabricate solar cells from silicon wafers under only ambient temperature and pressure conditions. They were surprised to find that their efforts produced worthy results after optimising process conditions for the wafers.

First, the polished wafers were diced into 8mm square pieces and, in a variety of sequences, were coated with PEDOT:PSS aqueous solution and silver electrodes.

“Our approach enabled us to achieve improved production speed at lower cost and with a power generation efficiency above 10%,” said Tanabe, who is an Associate Professor at Kyoto University.

Utilising the team’s production process for the future

The team believes that this new and more efficient production process could lead to large-scale diffusion of photovoltaic power generation. The system could be used in a variety of settings, such as in education or in developing economies.

“Next, we will focus on optimising impurities and additive concentrations in our production, as well as other structural innovations,” concluded Tanabe.