The Geomechanics Research Centre (GRC), where R&D plays a critical role in advancing the understanding of geomechanical challenges in mining with practical solutions to improve safety, efficiency, and sustainability.

MIRARCO (Mining Innovation Rehabilitation and Applied Research Corporation) is an organisation based in Sudbury, Ontario, Canada, primarily focused on research and development for the mining industry.

MIRARCO originated from ‘The Geomechanics Research Centre’ (GRC), which was established in 1987 at Laurentian University in Sudbury, Ontario, Canada.

GRC focused on geomechanics research to address challenges faced by the mining industry, particularly in the areas of ground control and rock mechanics. Over time, GRC evolved and expanded its scope, eventually becoming MIRARCO Mining Innovation in 1998.

MIRARCO continued to focus on mining research and innovation but over the years has broadened its mandate to include various aspects of mining operations including safety and sustainability.

As a hallmark of MIRARCO’s 25 years of operation, the GRC has been a core research area that has attracted hundreds of industry experts, researchers, and graduate students from all over the world to join MIRARCO and work on a multitude of industry focused challenges.

Geomechanics research: Past initiatives to future directions

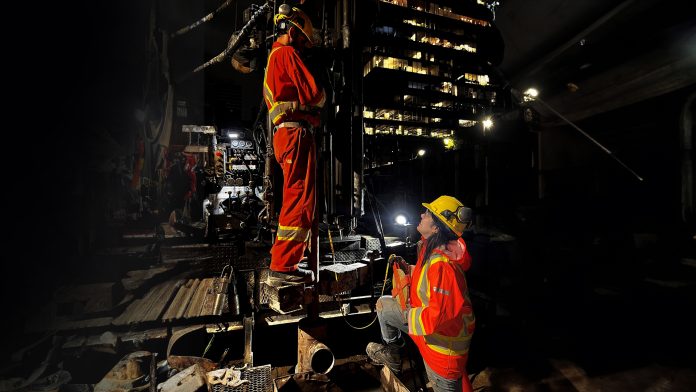

Our GRC team at MIRARCO conducts both research and testing to understand the behaviour of rock under various loading conditions encountered in mining operations. This includes investigating factors such as rock strength, stability, and failure mechanisms. The research results can be translated into innovative solutions and methodologies that can improve mining processes, enhance safety, and optimise resource extraction. We also provide training programmes, workshops, and technical support to help mining companies implement best practices in geomechanics.

At the same time, MIRARCO has been a key stop along the pipeline of engaging students throughout all aspects of a project, providing experiential training and industry experience before heading out into the workforce.

As an example, our GRC team have conducted an in-situ stress measurement through borehold overcoring that helps to assess the stress field in host rock at various mines and municipal projects across Ontario. The technology applied for these trials is determined by carefully assessing the client’s needs.

GRC has experience deploying both CSIRO Hollow Inclusion cells to determine 3D in-situ stress tensor, and USBM mechanical gauges for both 3D stress tensor and the horizontal principal stresses.

We routinely conduct rock characterisation in our service lab, which can assess peak, tensile, and sheer rock strength as well as determine their elastic properties, drillability, and hardness.

Mirarco continues to invest in our lab infrastructure and personnel to ensure the quality of these research and technical services to a range of industry clients.

On top of a solid track record of stress measurement and lab testing, GRC also offers additional field services such as shallow acoustic and optical televiewer surveying, geotechnical core logging, geotechnical mapping, and photogrammetry to the Canadian market. The GRC has recently finished an extensive production-level trial of applying hydraulic preconditioning to modify deep underground stress zones in the hope of reducing larger seismic events. The results of this study are still being compiled.

25 years on, MIRARCO is building from our strong track record to deliver robust research outcomes and solutions for our mining industry partners.

As mining expands globally, tackling more challenging ore deposits, heading deeper underground, MIRARCO is focused on applying solution-oriented approaches to help address these challenges.

The development of new techniques or technologies is most successful when researchers, students, and industry work jointly on projects or initiatives to best leverage academic vs industry knowledge. This makes MIRARCO an attractive partner for companies looking to overcome specific obstacles or improve their operations.

Please check our website to learn more about our service offerings and research projects under the Geomechanics Research Centre. A few examples of our ongoing research and partnership projects are featured below.

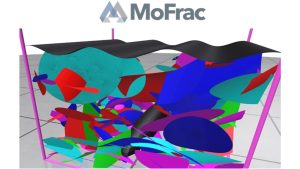

MoFrac: Software advances with enhanced speed and realism

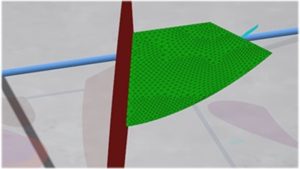

MoFrac is a discrete fracture network (DFN) modelling software developed by MIRARCO with the support of numerous funding grants and industry partners. The software is capable of simulating three-dimensional fracture networks constrained to known mapped geological data, such as fracture density, orientation, and fracture traces.

Mofrac has moved forward to a Phase 4 development stage, which aims at increasing the efficiency of the software and will develop new features that will enhance the generation of more realistic DFNs.

Major changes during Phase 4 of software development include parallelisation of the code using C++ with Message Passing Interface (MPI) capabilities to improve run time, spatial variability of fracture intensity, further propagation of a pre-existing discrete fracture network model, fracture clustering and branching, and the ability to incorporate borehole data as a constraint.

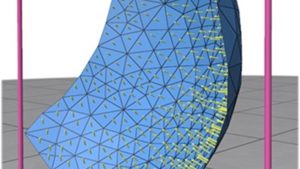

Unveiling SOT 5.0 with stochastic optimisation

Through a collaborative project, MIRARCO’s software team has been working closely with RPMGlobal’s Sudbury office to enhance the Schedule Optimisation Tool (SOT), a software tool for long-range optimisation of surface and underground mine plans. As the team progresses towards the release of SOT 5.0. the MIRARCO team has been the key developer for the features for stochastic optimisation.

Working with our collaborators from Queen’s University, the team will deliver software with new features that will be used to ensure optimised life-of-mine schedules are robust to uncertain product prices and ore grades.

New objective mine functions in SOT will maximise the economic robustness of a schedule, and the mine planner can configure distributions for product price simulations.

Ore grade simulations are either based on the resource category, or variances. Multi-objective optimisations are customised to corporate objectives, such as minimised economic risk with maximised economic value.

The new stochastic modelling provides risk management that complements SOT’s broad range of mine schedule optimisation capabilities. Mine operators using SOT 5.0 will realise even more value from their underground and open-pit operations.

Please note, this article will also appear in the 19th edition of our quarterly publication.