Professor Mark Anderson from the University of Wisconsin-Madison discusses some of the interesting experimental science questions associated with advanced nuclear system coolants and how reactors based on these technologies can help to reduce the environmental impact of power and heat production, as well as stabilising energy costs.

As the cost of energy continues to rise and concerns regarding carbon dioxide emissions grow, there has been a push for more sustainable and environmentally benign energy supply technologies. Society’s demand for consistent and stable energy generation continues to increase as we become more dependent on electricity, supplemental heat for industrial processes, and heating and cooling for comfort.

Currently, this reliance on immediate, reliable, and stable power and heat generation is at odds with most ideological motivations regarding pollution and climate change that results from the generation of energy for electricity, propulsion, and goods. This has accelerated the implementation of renewable sources of energy and the reduction of fossil fuel burning. Renewable energy (hydropower, wind, solar, and geothermal) has great promise but is not sufficient to provide the electrical energy demand required by both developed and developing economies. This, coupled with the need for thermal energy generation for district heating and a broad range of industrial applications, has led to the rethinking of nuclear energy as a needed viable clean energy source.

While it was once criticised by environmental action groups, nuclear energy is emerging as one of the only viable solutions for high-demand continuous energy generation. In reality, since its conception, nuclear energy has always been a relatively safe, efficient, and environmental solution1.

Due to the public’s perceived, and to some extent, justifiable safety concerns, significant regulations placed on nuclear generation over other energy sources, combined with licenses, citing regulation and construction issues, have made it expensive and not profitable without subsidies, which are typically provided to other environmental generation sources.

Realisation of history

Over the 51 years since electricity was first generated at the Experimental Breeder Reactor -1 (EBR-1) and the release of a music video ‘Clean Power Forever’2, with EBR-1 footage as a backdrop, there have been significant engineering and technical advances made to nuclear reactors, focused on increasing their efficiency and making them safer to operate. This includes the use of several different coolants including liquids (water, sodium, lead, salts) and gases (helium, CO2).

Recent investment in advanced nuclear technologies continues to improve safety, efficiency, and economics, which, alongside the need for clean power, has sparked renewed interest in advanced small reactor designs. Currently, there are over 50 different reactor developers worldwide, each with different reactor designs, that make use of some of these more novel high-temperature fluids (sodium and salt). In addition, there has been an insurgence of micro-reactors (nuclear batteries) adding even more technology options with the use of heat pipes and gas-phase Brayton cycles. These, as with conventional technologies, can also make use of thermal energy storage to improve the economics and overall utility of energy generation.

Significant advantages can be achieved using some of these unique coolants, specifically liquid sodium and salt, allowing the possibility of fast spectrum reactors that can utilise waste from water reactors, and reduce the number of radioactive by-products that would have to be stored for future use. It would also be possible to reduce operating pressure, enhance efficiency by increasing operating temperatures, and mitigate some of the safety concerns associated with lower boiling temperature fluids. Examples of sodium and liquid salt cooled reactors being developed can be found on TerraPower and Kairos Power’s websites.

Using sodium as nuclear system coolant

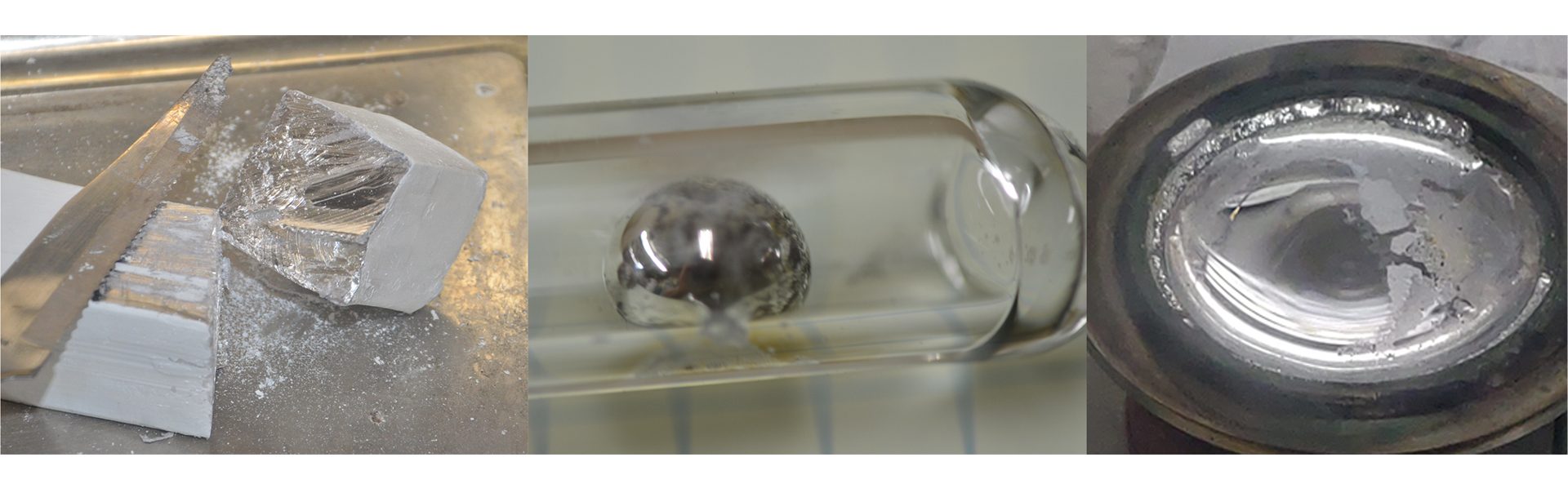

Sodium metal is used to transfer heat from nuclear fuel ultimately to the power cycle. At room temperature, sodium is like a metallic clay and above 100oC it flows like water but with a much higher thermal conductivity.

Sodium metal melts at 97.8oC and does not boil until 882.9oC under atmospheric pressure, which gives it a large and useful liquidus range without the need for pressurisation. Liquid metal has a very high thermal conductivity which makes this an excellent fluid to transfer heat from a reactor core to a power cycle (steam Rankine or gas Brayton cycle), or couple to a high-temperature thermal energy storage medium (such as nitrate salts). Sodium is also a good fluid from a neutronic perspective due to its low neutron absorption cross section and its short half-life.

Along with these benefits, there are challenges that have the potential to drive advancements in engineering, science and technology related to these reactor concepts. These advancements include high-temperature electromagnetic and centrifugal pump designs, oxygen and impurity sensing and control, erosion and corrosion, thermal stratification, thermal stripping, and fluid dynamic issues associated with the low Prandtl number fluid (~0.01).

As the electrical conductivity of sodium is 1012 times that of water and 106 that of salts, it is possible to move and measure the flow of liquid sodium with electromagnetic forces requiring no physical contact.3, 4, 5 This can lead to reduced pressure drops in the case of pump trips, allowing natural circulation to cool the reactor (remove decay heat) once it is shut down and enable easier repair and less operation and maintenance issues.

Liquid sodium is reactive with oxygen in the air and the presence of oxygen can increase the corrosive nature of the sodium against alloys such as 316 stainless steel, which is typically low, provided the oxygen concentration is kept below 4 ppm. To ensure the reactor operates under these conditions, coolant monitoring is required; this can be achieved electrochemically, optically (sodium is transparent at short wavelengths6), through the use of plugging meters which indirectly monitor the precipitation of NaO2 as the temperature of the sodium is decreased7 or through vanadium wire equilibration8.

The fact that sodium is very thermally conductive and has a low Prandtl number can also lead to issues with thermal striping.9,10 This phenomenon results from thermal oscillations near a wall caused by, for example, the mixing of two different temperature streams (hot and cold). If these different streams mix next to a wall, it can result in oscillatory thermal stress in piping carrying the fluid which could eventually lead to a structural failure. Thus, it is important to understand these mixing phenomena and design systems accordingly. These are only a few examples of different areas that are being researched to improve the use of sodium as a coolant.

Molten Salt Coolants

Flibe salt can be used as a reactor coolant or combined with a fuel salt. High purity salts can be made to limit corrosion, they, similarly to sodium, can flow like water and be pumped through reactors and test loops. However, when in contact with air or moisture, they can be very corrosive.

Salts can be used as high-temperature heat transfer fluids or even as fuel if they are mixed with uranium or thorium-bearing salts11 . The salts used are typically mixtures of several components which reduces the melting temperatures to below 450oC. These salts have high boiling or decomposition temperatures, giving them a large range of operational temperatures at atmospheric pressures.

The benefits of these salts include high energy storage capability (product of heat capacity and density ~3-5 [MJ/m3-K]), while also being able to pump at low pressures and operate at high temperatures. The use of these high-temperature liquid salts as coolants and thermal energy storage media has been studied in the past during the Molten Salt Reactor Experiment (MSRE) conducted at Oak Ridge National Laboratory, but their resurgence has led to interesting research areas focused on understanding the engineering details associated with dealing with these high melting temperature coolants. This research includes purification and monitoring of the purity of the salts, development of pumps, valves, bearings, and seals, understanding of the corrosion on materials in air and under inert environments, migration and deposition of fuel, and the development of detailed instrumentation that allows real-time health monitoring to provide a prediction of any potential issues12,13.

Towards sustainable energy generation

Nuclear reactors can offer a viable and sustainable solution to environmental energy generation. On top of this, new advanced concepts and technologies utilising high-temperature fluids are paving the way for safer, more efficient, and more sustainable electrical and industrial heat generation, which is something that renewable sources cannot do. From a physics and scientific standpoint, several different concepts have vast potential for future improvement and advancements through focused research. Finally, this method can become cost-competitive provided substantial factory fabrication, standardisation of the balance of the plant components14, the inclusion of thermal storage, the use of advanced but standardised components, and advanced power cycles designed to improve the efficiency of higher temperature reactors. With the development of these advanced nuclear system coolants, there is much work to be done for the reactors to reach the standard of the current fleet of water reactors.

References

- Rhodes, R., Energy. 2018: Simon and Schuster.

- Meyer, E. Clean power forever. 1951.

- Weathered, M., et al., High-Temperature Sodium Submersible Flowmeter Design and Analysis. IEEE Sensors Journal, 2021. 21(15): p. 16529-16537.

- Anderson, M.H., Rein, Jordan, Hvasta, Mike, and Nollet, William. E., Enhancement of EM Pump Performance through Modeling and Testing. United States: N. p., 2019. Web.

- Hvasta, M.G., W.K. Nollet, and M.H. Anderson, Designing moving magnet pumps for high-temperature, liquid-metal systems. Nuclear Engineering and Design, 2018. 327: p. 228-237.

- Daido, H., et al., Demonstration of partially transparent thick metallic sodium in the vacuum ultraviolet spectral range. Optics Express, 2013. 21(23): p. 28182-28188.

- Nollet, B.K., et al., Development of an Electrochemical Oxygen Sensor for Liquid Sodium Using a Yttria Stabilized Zirconia Electrolyte. Journal of The Electrochemical Society, 2016. 164(2): p. B10-B22.

- Smith, D.L., Investigation of the thermodynamics of V-O solid solutions by distribution coefficient measurements in the V-O-Na system. Metallurgical Transactions, 1971. 2(2): p. 579-583.

- Weathered, M., et al., Characterization of Thermal Striping in Liquid Sodium With Optical Fiber Sensors. Journal of Nuclear Engineering and Radiation Science, 2017. 3(4).

- Schneider, J. and M. Anderson, Using optical fibers to examine thermal mixing of liquid sodium in a pool-type geometry. International Journal of Heat and Mass Transfer, 2020. 158: p. 119968.

- Britsch, K. and M. Anderson, A Critical Review of Fluoride Salt Heat Transfer. Nuclear Technology, 2020. 206(11): p. 1625-1641.

- Alexander Heifetz, M.W., Nathan Hoyt, Mark Anderson, Scott Sanders, Anthonie Cilliers, New sensing technologies can reduce O&M costs to ensure advanced reactors’ economic viability. Nuclear Newswire, Dec 23, 2021.

- Becker, K.F. and M.H. Anderson, Optical Fiber-Based Level Sensor for High Temperature Applications. IEEE Sensors Journal, 2020. 20(16): p. 9187-9195.

- Moneghan, D., Cost Drivers of nuclear steam cycle construction. ANS/ Nuclear Newswire, 2022.