Elizabeth Sooby PhD, Assistant Professor at The University of Texas at San Antonio, discusses the need for fuel innovation and discovery to enable advanced nuclear reactor technology.

I like to imagine a nuclear fuels market where a reactor designer can shop for fuels in a similar fashion to how an interior designer shops for tiles.

The reactor designer can bring their operational envelope, meaning their inlet and outlet coolant temperatures, neutron fluences, design basis accident scenarios, primary and secondary coolants, etc. Then a fuel vendor could provide options to maximise the reactor’s performance. However, in the US today, the one and only licensed and qualified commercial fuel form has remained almost unchanged since the 1960s. As such, commercial, power-producing reactors are almost exclusively operated with a uranium dioxide (UO2)-based fuel form. There are a modest number of fuel vendors globally who supply this UO2 fuel encased in a zirconium-based cladding. It is important to note that other fuel forms are used in research reactors and test reactors1; however, for commercial cores, UO2 is not only the ‘gold standard’, but it is the only option for fuel, at least here in the US.

Accident tolerant fuels

Following the Fukushima Daichi accident in 2011, global efforts increased to bring to market so-called ‘accident tolerant fuels’ (ATF)2 which initially appeared to provide the opportunity for a significant departure from the long-held industry standard. The goal of the accident tolerant fuels program is to extend the coping time of a light-water reactor (LWR) fuel form.3 Essentially, a global community of scientists, engineers, utility companies, and fuel vendors spent a decade assessing options and advancing the state of knowledge of nuclear fuel technology to determine a replacement for the traditional fuel form that was both economically viable and could withstand a loss of coolant accident for a longer period of time before radioisotope release occurred. To do this, the thermal conductivity and oxidation resistance of the nuclear fuel form needed to be increased, along with several other desired fuel performance metrics.4 At the end of it all, the US ATF community settled on two classes of ATF candidates: near-term and long-term. The near-term solutions are incremental advancements to traditional UO2 in zirconium cladding with coatings to the cladding implemented to increase oxidation resistance and dopants to the UO2 to enhance thermal conductivity and fission product retention.

During the spring of 2011, at the time of the third major accident in the history of nuclear energy production, I was a graduate student at Texas A&M University working on a PhD in Physics. My dissertation project was focused on advancing the state of knowledge of uranium-based molten salts for a proposed accelerator-driven system5 – a nuclear reactor core which uses a particle accelerator as the ‘on/off switch’ for the fission chain reaction. In 2022, molten salt is now a key focal point in the nuclear community to be used as either the coolant or the fuel; however, in 2011 when I was hunting for supplemental funding to complete my dissertation research, salts were nowhere near the top of the priority list for the U.S. Department of Energy’s Office of Nuclear Energy. What was at the top of the list and became the field of fuels research I would spend my postdoc and early tenure track engaged in, was accident tolerant fuels.

Materials for increased performance of nuclear reactors

As I have already eluded, the massive R&D undertaking resulted in the deployment of incremental advancements to traditional oxide fuel, but it also assessed materials which had yet to see significant investigation for light water reactor implementation. While I was a postdoctoral fellow at Los Alamos National Laboratory, we tested everything from molybdenum to steels to silicon carbide for cladding candidates and advanced both the fabricability and thermochemical understanding of several novel fuel compounds including uranium silicide, uranium nitride, and uranium boride compounds. Therefore, the lack of commercial fuel options is not due to a lack of innovation and creativity in the nuclear fuels community, nor is it due to a lack of materials candidates which can bring about improved performance of our current fleet of reactors and enable revolutionary designs for the future of nuclear energy.

In contrast, it is more because of limitations in either performance in water-cooled reactors and/or qualification data to substantiate the licensing of these fuel materials. By performance, I mean economics of the fuel, as well as safety under normal operating, transient and beyond design basis accident conditions. Many of these materials would increase the operational performance of a light-water reactor but would interact with the coolant in the event the cladding tube was compromised. However, if we look to a reactor design that does not employ a water-based coolant, an advanced gas reactor for example, the opportunity arises for these fuel forms. Advanced reactors present a playground for nuclear materials scientists, and the fundamental research to determine the operational envelope of these fuels is necessary to bridge the gap in the unknown. After being immersed in the advancement of novel nuclear fuel forms for over a decade, I want to focus on two research themes which preclude a reactor designer from having their ideal fuel-shopping experience, and thereby limit the societal promise of nuclear energy: fundamental chemistry and irradiation effects.

Fuel chemistry

To lay the technical groundwork we need to discuss the issue of fuel chemistry. For clarity, I will define ‘fuel’ as the uranium-bearing compound or alloy and ‘fuel form’ as both the uranium-bearing component and the primary and even secondary containment of the uranium fuel and the fission products produced during operation of the reactor. The fuel for conventional commercial reactors is UO2 in a cylindrical geometry, which is often doped by a vendor to enhance performance factors like fission product retention and thermal transport properties, where the fuel form is a bundle of fuel pins, and a fuel pin is comprised of a stack of UO2 pellets 1cm in diameter, in a zirconium-based alloy tube which is metres in length. When discussing fuel forms, there are several proposed designs, including pebbles, which have fuel particles dispersed. In a particle fuel concept, the kernel or inner most component of the particle is the uranium-bearing fuel and that fuel is surrounded by refractory layers designed to absorb and retain fission products. For most particle fuel concepts, the particle is less than a millimetre in diameter and the pebble, which uses graphite and resin to mould hundreds of thousands of particles in a soft ball-sized sphere, comprises the fuel form. There are mobile fuel concepts where the fuel, uranium, is dissolved in a fluid, like a molten salt, and circulated around the core, or even fuel forms which are particles dispersed in a matrix material, like silicon carbide, which is additively manufactured to have the coolant channels engineered into the fuel form itself rather than the other solid fuelled cores which have arrays of fuel forms which the coolant flows around. In short, there are a multitude of forms proposed for a variety of advanced reactor types, and each one comes with its opportunities and challenges to qualification and licensing.

Thermochemistry of molten fuels and coolants

Some reactor fuel concepts have straightforward questions to be answered. For example, in the case of a molten salt reactor where, for instance, the fuel is UCl3 in a host salt of NaCl and KCl, a reactor designer must determine what material to use for the reactor vessel, which contains the liquid phase fuel, as well as the coolant channels. The first metric which comes to my mind is the corrosion rate of the molten salt. In the simplest and most ideal case, the salt is pure and induces some corrosion rate that is dependent on the thermo- and electro-chemistry of the salt when in contact with the metallic (think steels or nickel-based superalloys) or refractory (think SiC) vessel wall. However, once the fission process begins, and even in some cases before it begins, impurities which drive varied corrosion dynamics are introduced. The age-old comparison is the water heater in your home where, in pristine condition and with clean, high-purity water, the system can operate in your home for decades. However, if hard water or metallic impurities are introduced, parts of your hot water heater vessel will corrode at a much more rapid rate and potentially cause a leak in your home.

There are ongoing efforts to thermochemically model these complicated, molten salt systems, and, if you think back to your high school or even university level chemistry class, you can predict whether a reaction will occur if the reaction products have a lower energy state than the reactants themselves. So why can we not assume there are all kinds of impurities in this salt at various levels and start to predict reaction rates and products? Well, this brings about two challenges that my laboratory actively focuses on for various fuel forms and reactor designs. The first is that, whilst thermochemistry can inform on whether a reaction will occur, it does not provide the rate of the reaction. For example, if you place a piece of aluminium out in your yard, thermodynamics will tell you that it will convert entirely to an aluminium oxide spontaneously; in reality, the first thin layer of oxide becomes what we know as a diffusion barrier to further oxidation in many conditions and the reaction slows to a point where you would need to let the piece of aluminium sit outside for centuries to have it fully convert to Al2O3 in that environment. Thereby, we work to measure corrosion and diffusion rates experimentally at the temperature and in the atmospheres relevant to specific reactor designs, so that we can inform on the kinetics of the reaction in addition to the thermochemistry of the system.6,7 Where this becomes even more challenging is under accident conditions for solid-fuelled reactor designs, such as light water reactors and advanced gas reactors, where temperatures can exceed 1200oC and atmospheres are complicated by coolants in vapour phases, in addition to a host of other secondary reaction products, like CO and CO2 in the case of an advanced gas reactor.8 What proves even more challenging at times is the second scientific issue – specifically, we frankly do not know all the chemical species which can form under these conditions. So, this poses the question as to what the impacts of the unknown are.

Thermochemistry complications of uranium silicide fuel

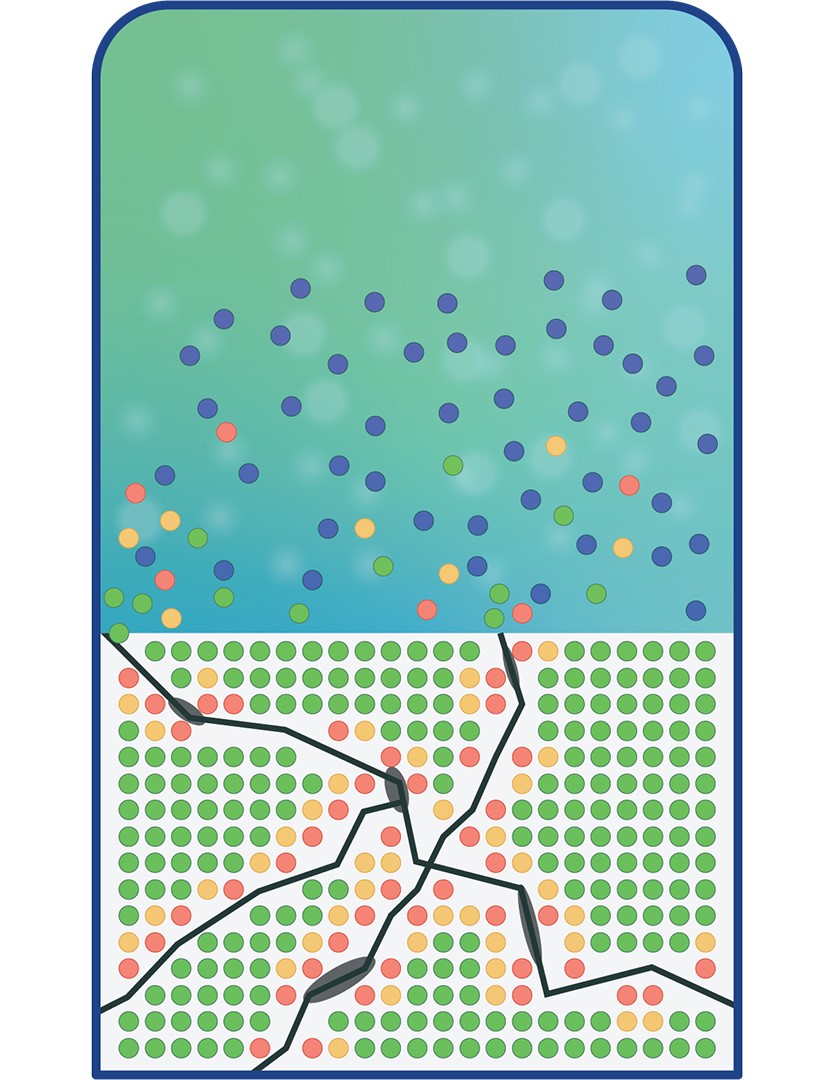

To better elucidate this second challenge, particularly the challenge of the unknown reaction product, we need to look at a uranium silicide fuel, U3Si2. U3Si2 is traditionally known as a plate-type reactor fuel for research reactors where it is dispersed in aluminium. It has a higher uranium density, or more atoms of uranium per unit of volume, than UO2, making it very attractive to utilities and fuel vendors because they can make more power per fuel bundle if it were to replace UO2. In addition, it has much better thermal transport properties,9 which implies it would perform better during irradiation and under some reactor transients due to the reduced thermal stresses compared to its oxide counterpart. With all this promise, we undertook a campaign to assess how this fuel would perform if it was exposed to the coolant of a light water reactor. At the start of the experimental effort, we knew a couple of things: the uranium in the silicide would form UO2 and the silicon would form SiO2. We also knew that the uranium-forming UO2 would probably happen quickly but, since SiO2 forms a passivating oxide, (much like that piece of aluminium you now have in your backyard), there was a chance it would be stable under coolant exposure, at least up to 1200oC, which is the temperature where SiO2 begins to degrade in steam.

What we observed, and then studied for half a decade, was the formation of a hydride phase that was previously unknown and unobserved, which caused total pulverisation of the fuel when it was exposed to water, even before significant amounts of UO2 formation.10 Following these observations, much of the academic fuels community, which was really rooting for U3Si2 to be a viable water-cooled reactor fuel, shied away from high uranium density compounds, including others which could lead to even better performance properties if properly prepared – an example of this is uranium nitride (UN) which would need isotopic separation of the natural nitrogen to be a fuel contender, and has significantly increased uranium density and thermal transport properties to even U3Si2.11 UN is actively investigated as a fuel form for both particle fuels, as well as for nuclear thermal propulsion.

Future prospects for nuclear energy

Looking forward to the future of nuclear energy, which will include small modular reactors, molten salt reactors, and advancement in nuclear thermal propulsion, there will not be a ‘one-fuel-fits-all’ solution. The basic R&D needs therefore remain advancing the state of knowledge of nuclear fuel chemistry during operational and transient conditions. This includes accident testing in relevant atmospheres to the various reactors proposed, as well as fundamental chemistry investigations which aim to build a database of thermochemical properties to inform reactor designers and regulatory bodies on the ramifications of an accident, which bring about complex chemical atmospheres at temperatures where thermodynamics and kinetics are known to compete.

Furthermore, there is no replacement for irradiation testing. I cannot think of a comparable system to a nuclear reactor fuel form under irradiation with respect to non-equilibrium dynamics and thermochemical complexity. Thereby, together with innovative reactor design and material discovery, we must find a way to bridge the gap in irradiation data. Even if we find the best possible fresh-fuel solution, there is truly no way to predict irradiation behaviour of novel materials in core without exposing it to neutrons and inducing fission.

References

- Nelson, A T and P Demkowicz, Other power reactor fuels, in Advances in Nuclear Fuel Chemistry. 2020, Elsevier. p. 215-247

- Zinkle, S J, et al., Accident tolerant fuels for LWRs: A perspective. Journal of Nuclear Materials, 2014. 448(1): p. 374-379

- Goldner, F Development strategy for advanced LWR fuels with enhanced accident tolerance. in Enhanced Accident Tolerant LWR Fuels National Metrics Workshop. 2012. Germantown, MD

- Bragg-Sitton, S, Development of advanced accident-tolerant fuels for commercial LWRs. Nuclear News, 2014. 57(3): p. 83

- Sooby, E, et al., Candidate molten salt investigation for an acceperator driven subcritical core. Journal of Nuclear Materials, 2013. 440(1-3): p. 298-303

- Sooby, E S, et al., Steam oxidation of uranium mononitride in pure and reducing steam atmospheres to 1200°C. Journal of Nuclear Materials, 2021: p. 153487

- Wood, E S, K Terrani, and A Nelson, Sensitivity of measured steam oxidation kinetics to atmospheric control and impurities. Journal of Nuclear Materials, 2016. 477: p. 228-233

- Sooby Wood, E, J Vandegrift, and B J Jaques, Steam Oxidation in Accident Conditions, in Reference Module in Materials Science and Materials Engineering, R. Stoller and B.A. Pint, Editors. 2020

- White, J T, et al., Thermophysical Properties of U3si2 to 1773K. Journal of Nuclear Materials, 2015. 464: p. 275-280

- Sooby Wood, E, et al., U3Si2 behavior in H2O: Part I, flowing steam and the effect of hydrogen. Journal of Nuclear Materials, 2018. 501: p. 404-412

- Watkins, J K, et al., Challenges and opportunities to alloyed and composite fuel architectures to mitigate high uranium density fuel oxidation: Uranium diboride and uranium carbide. Journal of Nuclear Materials, 2022. 560: p. 153502