Fifteen of the UK’s leading chemicals and pharmaceutical companies are collaborating on the Flue2Chem project, which aims to reduce carbon emissions by converting industrial waste gases into sustainable materials.

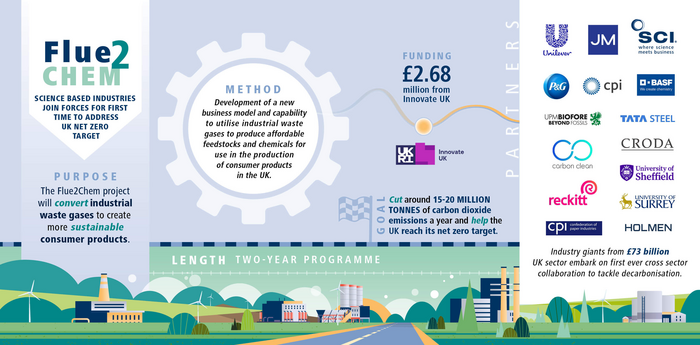

The Flue2Chem collaboration involves leading players in the UK’s £73bn chemicals and pharmaceuticals industry, including the Society of Chemical Industry (SCI) and Unilever. The organisations have signed a collaboration agreement to increase sustainability in the country’s consumer products industry by converting industrial waste gases into sustainable materials on a demonstration scale.

The project has been awarded £5.4m, of which £2.68m is funded via UKRI’s Transforming Foundation Industries (TFI) Challenge –established to drive the UK toward achieving net zero targets.

David Bott, SCI’s Head of Innovation, commented: “This is an excellent example of the power of collaborative working. It is an important step for the UK and SCI’s vision of furthering the application of chemistry and related sciences into the industry for public benefit.

“The new business model will aim to reduce the need for imported fossil fuel material. Instead, the consortium will build a new, more sustainable supply chain whilst also mitigating industrial waste emissions. The group will develop methods for using carbon captured from waste streams of other industries and transform them into affordable raw materials for consumer products.”

The UK needs to reduce its carbon-containing materials consumption

Currently, the majority of carbon that is employed to manufacture plastics, cosmetics, synthetic textiles, and other products is sourced from coal, oil, and gas. The UK imports substantial amounts of carbon-containing feedstocks annually in the consumer goods industry.

This means that for the UK to achieve its 2050 net zero targets, alternative carbon sources must be innovated for these goods and building domestic sources for carbon will help establish a lucrative UK value chain.

Project leader Ian Howell, Unilever’s Home Care Science & Technology R&D Director and Chair of SCI’s Sustainable Materials for Consumer Products Group, said: “This is a game-changing opportunity to accelerate action and rewire the chemicals value chain to be less reliant on fossil fuels.

“It’s a bold ambition and one that, at Unilever, we have been publicly calling for action over the last two years. No single company can do this alone, so to have the power of 15 manufacturers and academics marks a significant step forward not only for the UK but globally too.”

What will the Flue2Chem project involve?

The aim of the project is to utilise industrial waste gases from foundation industries, such as metals, glass, paper and chemical production, to develop an alternative source of carbon for UK consumer products. One of the main goals of Flue2Chem is to demonstrate how the UK can cut 15 to 20 million tonnes of carbon emissions per year.

In addition, the business model development will identify the economic incentives for the project and bring in international partners across the entire supply chain.

Bruce Adderley, Innovate UK Challenge Director for the Transforming Foundation Industries Challenge, concluded: “Underpinned by circular economy thinking, the Foundation Industries and their supply chain partners are bringing forward a range of new innovations as they move towards a sustainable competitive future. But these need to be demonstrated at scale if they are to be rapidly deployed in the UK and taken to international markets. That is why we are delighted to be able to support projects like Flue2Chem, which have huge potential to address decarbonisation through multi-industry collaboration focused on resource and energy efficiency.”