A new H2020 project is using hybrid testing methods proven in other industries to create a new hybrid testing platform for wave energy converters.

For wave energy development to take the next step forward, transformation is needed in the testing process. More efficient, accurate and flexible testing methods are essential to keep pace with the rapid advancement of technology. A consortium of European partners is taking on this challenge through the Horizon 2020-funded ‘VALID’ project.

Launched in December 2020, VALID (Verification through Accelerated Testing Leading to Improved Wave Energy Design) is developing a Hybrid Testing Platform for accelerated testing with methodologies by combining the virtual and physical environment, reducing cost in the product development process, tackling scaling challenges, and lowering uncertainties once fully demonstrated in the ocean.

“This ambitious project will provide a step change in the testing and standardisation of ocean energy devices and components,” Pierre Ingmarsson, RISE Senior Project Manager and Project Co-ordinator for VALID, said. “It provides an open platform for hybrid and accelerated testing that will ensure the reliability, availability, maintainability, and survivability during the lifetime of the technology, ensuring cost-efficient solutions.”

VALID draws on expertise from leading research companies (Fundación Tecnalia Research & Innovation, RISE Research Institutes of Sweden AB, Biscay Marine Energy Platform SA), academic institutions (Aalborg University and Technical University of Delft), as well as industrial experts across Europe (CorPower Ocean AB; Rina Consulting Spa; Idom Consulting, Engineering, Architecture S.A.U; AVL List GmbH; Yavin Four Consultants; Wavepiston AS; Aquatera Sustainability Ireland Ltd; and consulting engineer Julia F. Chozas).

What is hybrid testing?

Hybrid testing is an innovative and cost-effective way to evaluate structures, where the full engineering system is divided into physical and numerical subsystems/components. The idea is to numerically represent part of the substructures using well-established mathematical models, while physically testing the rest of the substructures that may have complicated or unknown mechanical properties.

In the automotive industry, hybrid testing has become common practice due to market pressure to significantly shorten time-to-market as well as tougher demands on performance and reliability.

AVL has been a front-runner in this transition during the last ten years, supporting major players in the automotive industry to overcome both technical as well as organisational challenges. They have achieved this through their Integrated and Open Development Platform (IODP).

The IODP offers the capacity to integrate the physical and the virtual world whilst being open to users’ diverse landscape of methods and tools. Because each organisation relies on different tools and processes, the IODP acts as a communication layer to effectively exchange information – often in real-time. The IODP software simplifies the deployment of hybrid testing by acting as unique interface to the different development process tasks and teams.

Cross-sector collaboration

As a VALID partner, AVL is now applying its hybrid testing methods through IODP software to the wave energy sector. Hybrid testing will allow VALID supply chain partners, developers, and the assisting research and development institute to integrate the inputs from their different laboratories across Europe.

“AVL feels very privileged to participate in this project,” AVL Executive Director Wilhelm Graupner said. “It allows us to learn about a dynamic and highly relevant emerging sector. At the same time, we can showcase how an integrated and open development platform allows us to bring better products into use while being faster and using less resources.”

During the life of the project, the IODP will be adapted to create the VALID Hybrid Test Platform, addressing the specific needs of the wave energy sector. By building upon a tool proven not only in the automotive industry, but also in aerospace and wind energy, VALID partners hope to make hybrid testing in the wave energy sector a reality.

©CorPower Ocean

Trialling the methodology

The core of the VALID project is based around three different case studies that involve wave energy developers adapting the Hybrid Testing methodologies used by AVL and the automotive industry to transform the fundamental approach to accelerated testing.

“Each user case is linked to a technology developer that will bring to VALID physical test rigs, representative numerical models of their devices (virtual test rigs) and high-fidelity data from the operation in real environments obtained in past, ongoing and future open-water sea-trials,” Ingmarsson said.

Through these case studies, project partners hope to integrate both reliability and survivability testing methods together with relevant data on component failures early in the design and testing process.

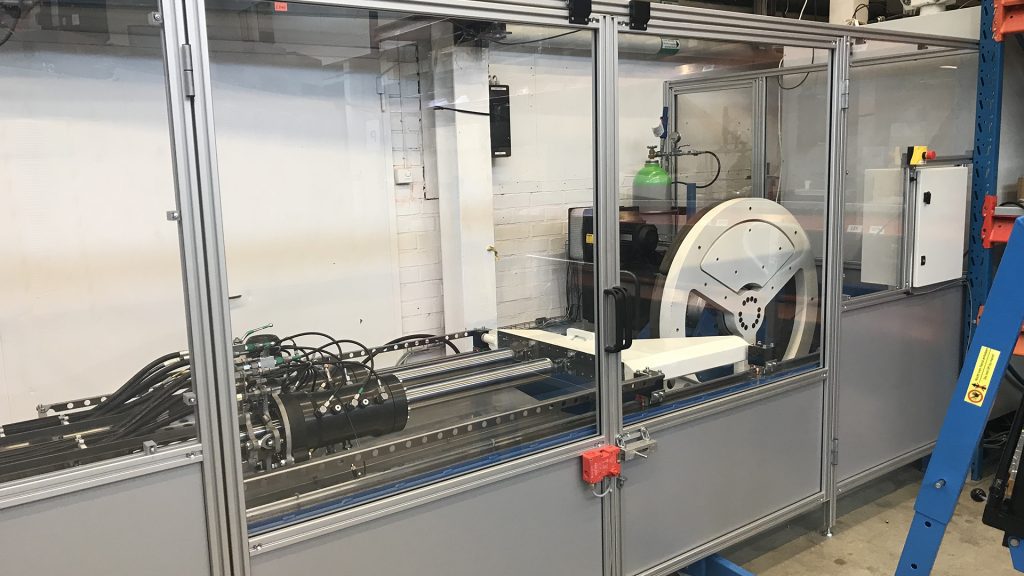

In User Case I, CorPower Ocean is testing dynamic sealing failures on the PTO of its point absorber Wave Energy Converter (WEC). During an earlier H2020 project, WaveBoost, several components of the sealing systems were identified as critical. The novel methodology developed in VALID will be applied in CorPower’s physical test rig for seal testing. It is being customised and re-built to enable an improved understanding of scale effects, sea water exposure, and various types of rod coatings and sealing components.

Electric generator failure is the focus of User Case II. Using IDOM’s floating device, Mutriku fixed Oscillating Water Columns pilot plant and TECNALIA’s test rig facilities, the VALID project aims to validate how the proposed methodology can assist in the understanding and evaluation of failures in generators and power electronics that operate about 20% of the time over nominal power.

Wave energy developer Wavepiston is testing Hydraulic pump failure in User Case III. Potential failures in the functioning of the pump sequencing mechanism along with corrosion and salinity issues are being evaluated on Wavepiston’s device, which has been extensively tested in open sea at the DanWEC test site. Wavepiston deployed the first version of several full-scale WEC at PLOCAN, Gran Canaria in December. The data from these installations will be made accessible to the VALID project to compare test bench and real-sea testing results.

Wavepiston CEO Michael Henriksen said the company is excited to take part in the first-of-its-kind project.

“With this accelerated testing, we can ensure better and faster input to design updates and preventive maintenance procedures, leading to a more durable system.” Henrikson said. “We expect our system to benefit from the accelerated testing of the seals and glider rings on our submerged hydraulic pumps, which is a critical subsystem common to many wave energy devices.”

Real-sea testing

Corrosion, ageing, and marine biofouling are all factors that can affect the life of the components being tested in VALID’s user cases. These are challenges not easily accelerated in a laboratory setting.

To properly test the performance of new materials and find solutions for these challenges, open-sea testing facilities from RISE, TECNALIA, and Aquatera will be a core part of the VALID project.

While reliable evaluating methods are in place for field testing, it is still a time-consuming process, especially for biofouling, which presents mostly in the summer months. To address the challenge of designing a device and its materials to withstand these real-sea conditions earlier in the development, lead project partner RISE has been gathering relevant information on biofouling organisms in Europe. Still, no tools are yet available to predict or simulate marine biofouling behaviour on different materials, geometry, or surface-finish. This is another challenge that VALID partners hope to tackle through the life of the project.

At the end of the three years, the consortium will have developed the new VALID Hybrid Test Platform (VHTP), along with testing methodologies that establish the correlation between ocean and lab conditions. Their hope is that the project can create common testing procedures and convergence in technology across Europe, advancing the development of wave energy technology.

References

1: Vinagre, P.A.; Simas, T.; Cruz, E.; Pinori, E.; Svenson, ‘Marine Biofouling: A European Database for the Marine Renewable Energy Sector’. Mar. Sci. Eng. 2020, 8, 495. https://doi.org/10.3390/jmse8070495

Please note, this article will also appear in the sixth edition of our quarterly publication.