Copper is vital for the green energy transition, and as demand rises, companies are exploring the potential of marine minerals.

The world is going through a major transition towards digitisation, electrification, and green energy.

The major component going into all these subjects is copper: the metal that has the best electric conductivity, is easy to form, and is resilient for long-lasting applications.

Copper has a high recycling rate, but copper’s demand will increase, and new reserves need to be added to the current reserves to ensure the future required stock.

The last major copper discovery was made in 2018, and there will be a future squeeze on demand if the mining industry doesn’t manage to add to the reserve bank. The preliminary signs of the squeeze can be seen by looking at trading prices and the sudden plummeting of the treatment charge – not enough copper is being mined for it to be transformed into the final product.

Green Minerals

As the Norwegian Government opened for mineral activity in January 2024, Green Minerals (ENX: GEM) has positioned itself as a frontrunner and a pioneer before the launch of the first licensing round in 2024.

The Norwegian Government started the process of opening the Norwegian and Greenland Seas to mineral activity with the Seabed Minerals Act in 2019. The schedule proposed when the act was approved has been strictly followed to this day. The process now moves into a new stage, and industrial actors are invited to take part.

Green Minerals’ vision is to create a full marine minerals value chain where we operate and co-ordinate the license through partners and affiliation, a model that has shown great value for the state and companies within the offshore oil and gas industry that Norway has developed with great success over the last six decades.

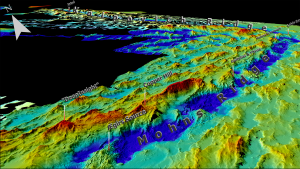

The Mohns and Knipovich ridges are located within the area the government has opened. They are ultra-slow spreading ridges with a high potential for hosting large Seafloor Massive Sulphide deposits, in-situ analogues of terrestrial Volcanogenic Massive Sulphides. These types of deposits have been mined by humans with high tonnages and high grades since copper was discovered as a metal. The potential of making large discoveries with high ore grades is significant for the first movers in the upcoming licensing round.

Green Minerals is a first mover and has built strategic alliances to become a successful operator. Our portfolio includes several very interesting prospects that we are now investigating upon the first licensing round and are eager to be allowed to explore further. The authorities, together with academic institutions, have achieved the initial mapping of several interesting deposits and locations, and the related data (valued at more than $50m USD) have been released to the industry.

Why go to the deep sea for copper?

Copper has been mined by men since the stone age; it is the most important raw material in the industrial age. Marine minerals have been the source of copper from ophiolite complexes during the entire time; it has just been mined on land after continental drift has placed them above sea level and shuffled them around a bit, and temperature and pressure have metamorphosed the rocks. We now have the knowledge and technology to go where they form. Some have expressed concerns about deep-sea mining, but mining raw materials in locations where we will get the most metal-per-kg of rock with the least environmental impact must be considered. Extinct seafloor massive sulphide deposits along mid-ocean ridges show the potential of discoveries in the magnitude of 10s Mt of ore with Cu grades of 4-6% and potential of byproducts such as cobalt.

A world-class consortium

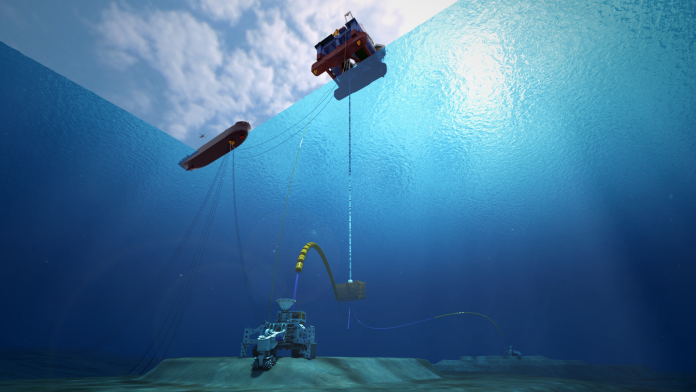

Since the late 1970s, we have known that lifting marine minerals is technically feasible (SEDCO in the Area). We also know that SMS can be extracted subsea and separated at the surface (JOGMEC, 2017). Nevertheless, these projects were test pilots, never designed to achieve commercial-scale production.

Validating the technical and economic feasibility of the offshore mineral production system is necessary for us and consistent with our holistic approach to the value chain. Green Minerals have thus entered into an agreement with a consortium of internationally recognised actors.

The consortium is led by the Oil States Industry (OSI), which delivered several riser systems to the marine mineral industry. Their riser equips The Metals Company (TMC) Hidden Gem and the Japanese research vessel, which recently completed a REE mud lifting trial.

Soil Machine Dynamics (SMD) is responsible for the design of seafloor mining machines. SMD has a solid backtrack of designing and delivering subsea intervention equipment and is also known for having delivered the subsea production tools of the former Nautilus Minerals, who endeavoured to mine SMS in the Bismark Sea.

The last piece of the puzzle is the participation of a pumping solutions provider that has supplied miners all over the world. After working for more than a year, we are concluding our concept study, which addresses the singularities of the Norwegian environment: harsh weather and long distance between the future work sites and the shore.

Our Chief Engineer’s PhD research has already highlighted the necessity of addressing ship-to-ship operations, which significantly contribute to the efficiency of a DSM system. Such operations include ore-offloading from the mining vessel to the bulk carrier, the transfer of personnel at sea, and other logistics issues.

Our concept is disruptive as many of the existing concepts assumed that ore would have to be stored on the mining vessel.

However, after investigating other solutions, we concluded that ore did not need to be stored on the mining vessel. We decided to transfer the dewatering and storing function to the ore carrier.

Enabling this functionality, we selected a technical solution using an O&G technology known as a disconnectable turret, a technology originally designed to enable the seasonal removal of FPSO in the Arctic. This technology allows us to positively decouple relative vessel motion challenges and act as a plug-and-play for the ore carrier: when an ore carrier is at full capacity, production halts, the disconnectable turret is lowered at a predefined storage depth and is ready for pick-up by the stand-by empty ore-carrier.

As a bonus, helicopter transfer of personnel is enabled as both the ore carrier and the semi-submersible are positively separated over a short distance and extremely stable, the two vessels being moored and not relying on dynamic positioning. The financials obtained during the concept study validate our preliminary assumptions, and we have not identified any showstoppers.

Can we process marine minerals?

The first study Green Minerals initiated was to understand the geometallurgy and processability of marine ore. Very little has been done on this subject over the years. As a junior mining company, it is vital to get control of the economics further into the value chain: no possible beneficiation equals no revenue and thus no rationale for exploration.

The Finnish Geological Survey (GTK), a globally recognised institution in the mining industry, thoroughly studied and characterised grab samples representative of ore from the Mid-Atlantic ridge to understand the ore mineralogy and texture and decide on the best processing methodology.

The specimens showed a very high abundance of coarse-grained pyrite, with relatively fine-grained chalcopyrite and chalcocite as other dominant minerals. Given the results of the geometallurgical characterisation, a standard flotation test was concluded to determine the concentrate grade and recovery factor of this type of deposit.

Another important axis of the testing programme was to blend subsea ore with existing ore from an operating low-grade Copper terrestrial mine to validate their genetic compatibility. The results of the test processing were above all expectations. Copper recovery results showed performance similar to land-based standards without additional treatments of the concentrate.

Further investigation is under consideration for recovering cobalt.

Why blend land and ocean ore?

Several copper mines in the Nordic countries have decreasing grades as they have been mined for several years. As the mine empties for good ore, the profitability of the marginal ore decreases. If we were able to blend with higher-grade ore from offshore mines, we could valorise marginal ore and subsequently extend the Life-Of-Mine. Within this scenario we do not need to build a concentrate facility for marine mines, and you can rationalise further existing facilities without using more ‘virgin’ soils.

What’s next for Green Minerals?

Norwegian authorities have recently started the award process for commercial licenses in the Norwegian-Greenland Sea; GEM has been working towards the opening for several years and has put a major effort into being in the best position possible for the first round.

Looking at Norwegian resource management history with the offshore oil and gas adventure starting in the ‘60s, all major oil and gas fields were discovered in licenses awarded in the early rounds, and the chance for history to repeat itself for deep-sea mining in Norwegian waters is high.

Please note, this article will also appear in the 18th edition of our quarterly publication.