Grounded Lithium Corp. has revealed its intended field development plan for the initial 10,000 metric ton/yr phase at the Kindersley Lithium Project (KLP) in Western Saskatchewan.

The development plan relies on and considers such factors as production testing, extensive dynamic fluid modelling, present land configuration, land tenure, topography, best practices in reservoir development and infrastructure availability. This analysis will contribute to completing a Preliminary Economic Assessment (PEA) on phase one of the lithium brine project, expected to be completed during Q2 2023.

Highlights of the field operational plan

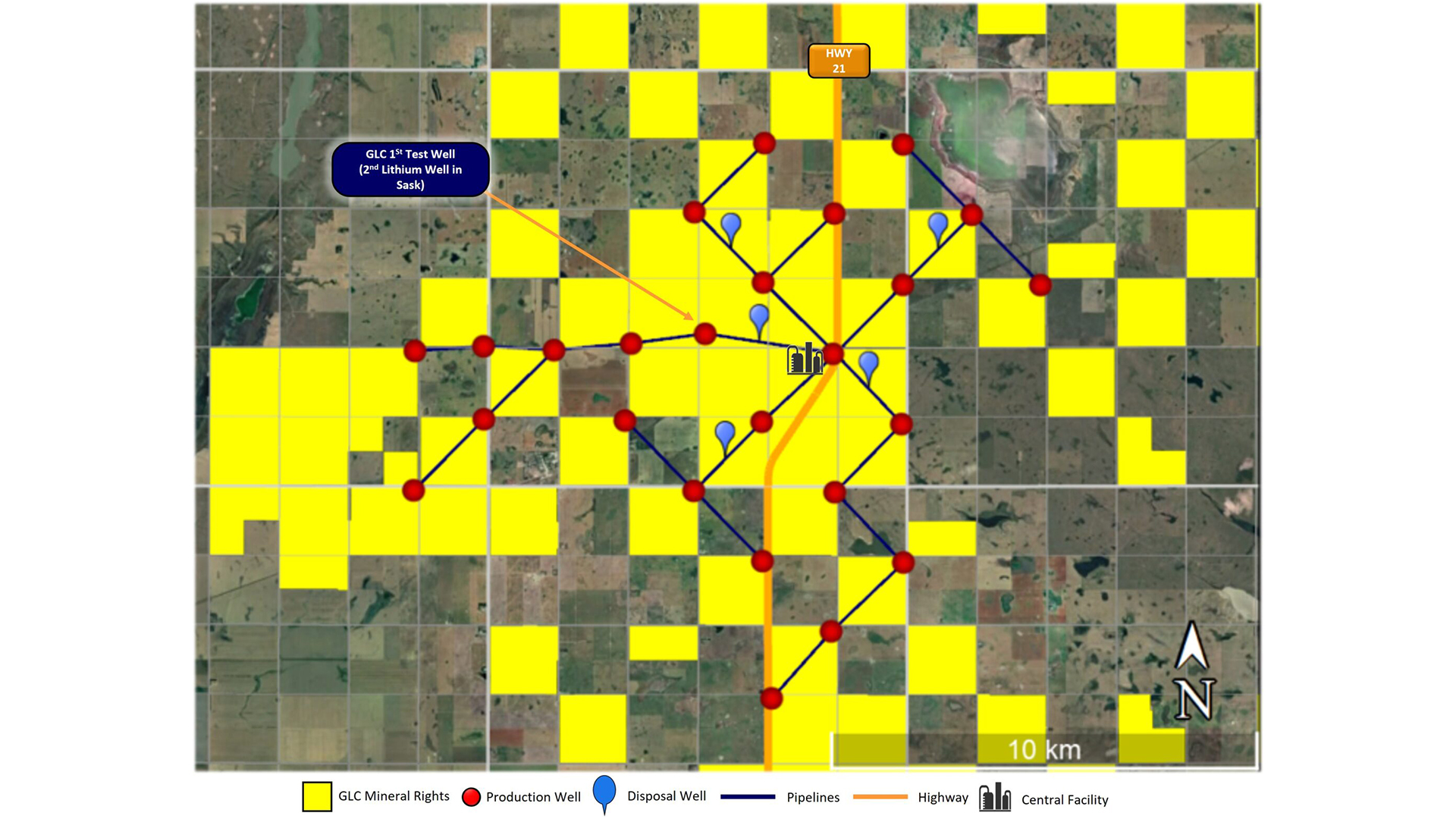

- Producing wells – only 24 additional producing wells are planned, given the strong grade and deliverability characteristics of the reservoir;

- Disposal wells – five injector wells;

- Pipelines – given strong reservoir characteristics resulting in a relatively small number of wells, only 70 kilometres of buried brine-capable pipelines should be required, significantly limiting surface disturbance; and

- Central processing facility (CPF) – an appropriately sized CPF will utilise economies of scale during construction. The CPF avoids incremental capital often associated with the removal of contaminants in the brine, such as trace hydrocarbons and H2S gases, as these are not expected to be present in GLC’s intended drill horizon.

This proposed development plan is shown below.

Gregg Smith, the President & CEO of Grounded Lithium, commented: “From our outset, we singularly focused on building the Company and its associated projects to generate cash flow and provide economic returns as quickly as possible. The current development plan is based on best practices in reservoir management collected by our team over decades of experience managing subsurface fluid production.

“The plan takes into account capital efficiencies wherever possible to ensure solid project economics, all while maintaining a reservoir that can deliver for years to come. We look forward to further elaborating on our efforts in this regard as we steadily advance to the completion of vital lab pilot work and associated technology selection, completion of a PEA and towards the end of 2023, potentially commencing construction of a field demonstration plant.”

A detailed assessment of the Kindersley Lithium Project

Field work completed over the last year confirmed a geologic view that the intended production zone is free of hydrocarbons and H2S, which materially reduces the cost of a full commercial plant since pre-treatment facilities will not be required to process these contaminants. With an initial project size of 10,000 metric tons/yr of battery-grade lithium salt, the Company’s initial processing facility maintains a smaller footprint and is expected to be located near key infrastructure such as paved highways, key power sources and several operational services due to its proximity to Kindersley, Saskatchewan. GLC’s full development plan calls for multiple 10,000 metric tons/yr ‘trains’ or phases which minimises the number of operational and financial risks, which ultimately is expected to drive incremental value for all stakeholders.

From an operational perspective, positive results from the field work evidencing grade and, more importantly for this type of operation, deliverability, results in a field development plan calling for only 22 producing wells, with five disposal wells. Aside from the initial test well, GLC will drill two additional producing wells to provide operational flexibility and redundancy to maintain consistent annual production rates. GLC’s field work further refined its three-dimensional dynamic model, enabling a more precise inter-well spacing and depletion plan through time. Additional capital savings are expected from the shallow depth to the intended horizon, materially reducing capital expenditures associated with drilling and ancillary services.

The infrastructure to connect wells to the facility requires only approximately 70 kilometres of buried pipeline for both production and disposal. Overall, the programme requires similar total wells to produce sufficient volumes for a 10,000 metric ton/yr project, but at approximately half the depth and with reduced facility requirements for brine prefiltering. KLP has the potential to be one of the lowest cost structure projects in the lithium from brine industry in Western Canada.

From a land tenure perspective, the location and selection of the drill program will earn or validate mineral permits which are leased from either the Crown (government) or freehold landowners. This development plan has an average inter-well distance between 1-1.5 miles, whereby individual sections in a checker-board manner can be developed. This model provides for infill development that can be employed for future growth or production maintenance if necessary.

When is the project scheduled to start running?

The Company anticipates lithium production commencement in the 2026 timeframe. Lithium from brine projects has the potential to reach commercial production far quicker than current global sources of lithium, which can often exceed a decade from concept to commissioning.

GLC plan to deploy direct lithium extraction technology to deliver an extremely economical project. Steady progress has been achieved in analysis and efforts with Hatch Ltd. to select the preferred technology to process brine chemistry from the KLP. The Company holds in secure storage more than sufficient quantities of brine to conduct longer-term lab pilot tests. Announcements will be forthcoming as the project evolves.