AmmPower is bringing clean energy to the world through the power of green ammonia, a natural chemical with 1.8 times the energy density of hydrogen.

Ammonia (NH3) is a colourless chemical, yet it is often referenced to as being ‘green’, ‘blue’, or ‘grey’. When ammonia is created, hydrogen and nitrogen atoms are combined to form the ammonia product, NH3. The colour prefix refers to the energy source used to power the process, defines how the hydrogen was obtained, and represents the impact of any associated emissions.

The traditional grey ammonia synthesis process uses fossil fuels, primarily natural gas, as a feedstock to generate hydrogen through steam reforming – a carbon-intensive process by which the issue of associated upstream carbon emissions remains even if the ammonia reaction itself does not generate emissions. Blue ammonia is a similar process, however the carbon-related emissions are captured and stored or utilised elsewhere. In fact, 98% of ammonia plants around the world use fossil fuels as a feedstock to obtain hydrogen for the ammonia synthesis process, according to the U.S. Energy Information Administration (EIA).1

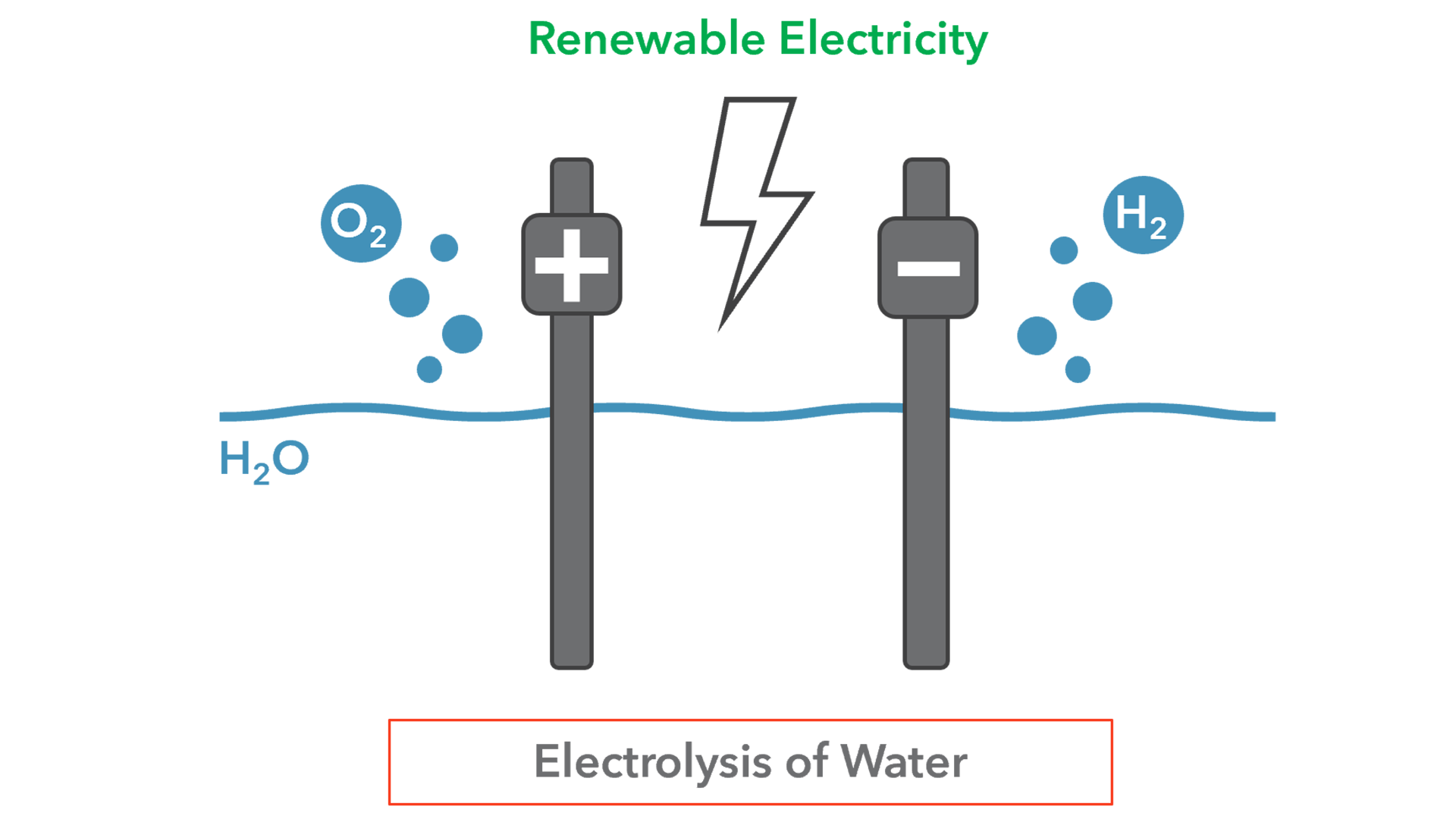

Green ammonia, however, uses green hydrogen and green energy to power the synthesis process. For hydrogen to be green, it must be made without using fossil fuels or producing carbon-containing greenhouse gasses. The most common method of obtaining clean hydrogen is through the electrolysis of water (H2O) which, simply put, is to send an electric current through water, thereby ‘electrolyzing’ it, to separate the hydrogen and oxygen atoms.

Ammonia impact

Ammonia is the second most widely used inorganic chemical in the world. In 2020, 176 million tonnes of ammonia were produced, resulting in approximately 500 million tonnes of carbon dioxide (CO2) emissions.2 Ammonia production accounted for 1.8% of all global CO2 emissions that year, and 80% of these were from isolating the hydrogen required for ammonia synthesis.

The power of green ammonia: How can it be utilised?

The advent of the Haber-Bosch process at the start of the 20th century enabled the quick manufacture of ammonia from hydrogen and nitrogen, providing an artificial way of fixing nitrogen into a form readily available for uptake by plants when injected directly into cropland soils.

Today, about 80% of all ammonia produced is used for agricultural fertilisers3, however a new purpose of ammonia has been discovered with the development of alternative fuel technologies, namely hydrogen.

Hydrogen (H2) is the most abundant element in the Universe, and its combustion results in water as a by-product. It can be utilised in sectors of the economy that have been historically hard to decarbonise, such as steelmaking and marine transport. It may also serve as a long-term storage medium in the power industry. Governments and industries around the world are increasingly focusing their efforts on building out the infrastructure necessary to support a hydrogen economy.

Among the major barriers to the widespread utilisation of hydrogen are the ability to move and store it prior to its end-use applications. Hydrogen can be shipped in tankers as a liquid, which can increase tanker load fivefold. However, liquid hydrogen requires temperatures under -253°C, and this process involves high capital costs and uses about 35% of the total energy content.

Ammonia can instead be a method of safely transporting hydrogen, requiring only slight pressure at ambient temperature to liquify.

Not only is ammonia an agricultural fertiliser and an optimal carrier of hydrogen capable of rivaling oil in this purpose, but it can also be used as an alternative, carbon-free fuel itself. It has 1.8 times the energy density of hydrogen and, when combusted, emits primarily water as a by-product.4

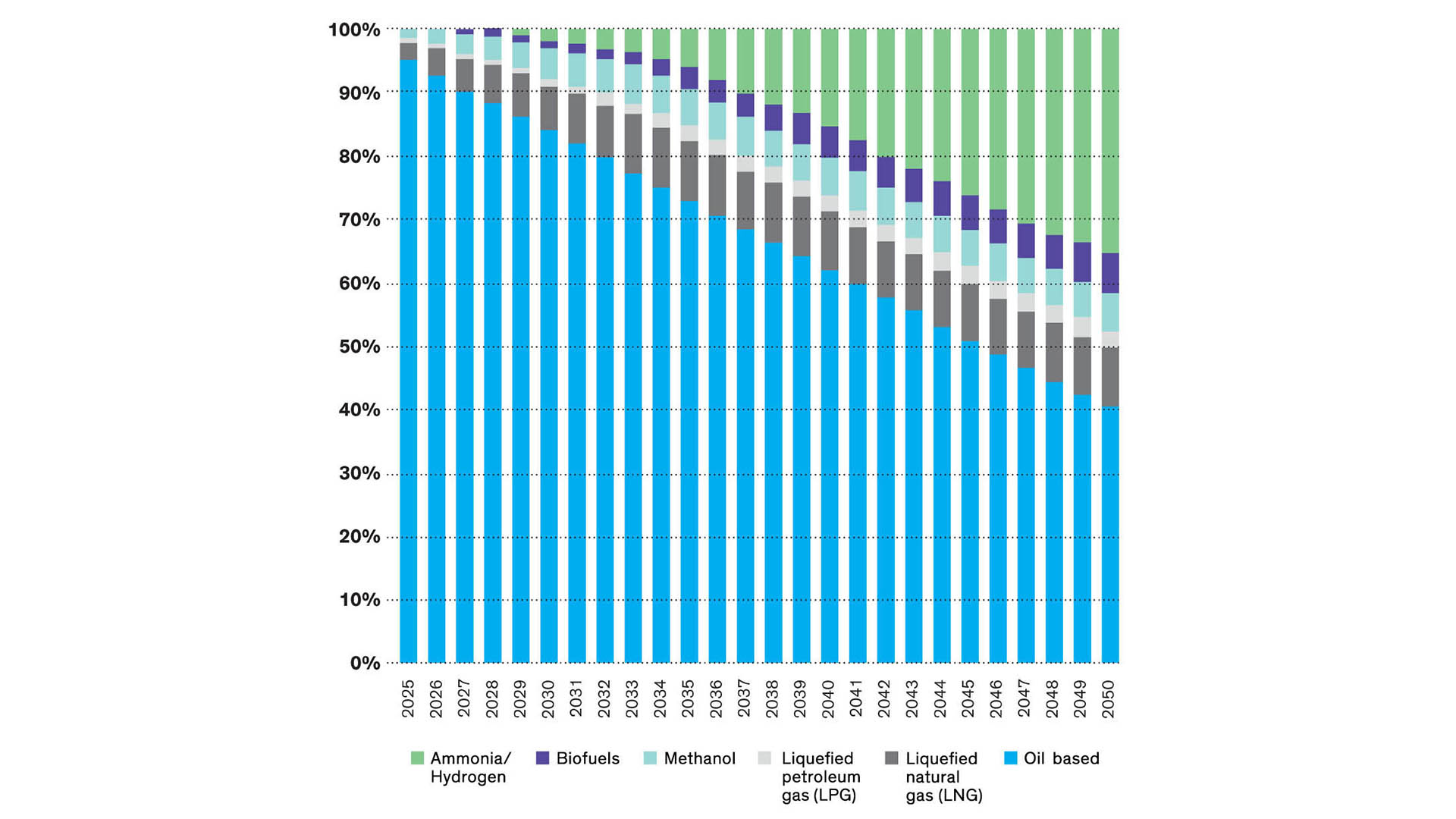

Ammonia may be the solution to the International Maritime Organization (IMO)’s pledge to reduce carbon emissions by 50% before 2050.

Ammonia maritime market

AmmPower Corp., a clean energy company focused on the production of green ammonia, is active in all facets of the ammonia market, including the production of green fertilisers, carbon-free shipping fuel, and the ‘cracking’, or moving of green hydrogen as ammonia.

The company is working on the development of proprietary technologies to produce green ammonia and green hydrogen at scale, including the investigation of unique catalytic reactions to bring down costs and to take advantage of carbon credits in the renewable energy space.

AmmPower will develop port facilities at strategic locations favouring the development of renewable energy projects at scale.

The company currently holds a Memorandum of Understanding (MOU) with Porto Central in Brazil, with the objective of installing a world-leading green ammonia facility in the port. This facility will produce roughly 4,000 tonnes of green ammonia per day, servicing the shipping industry for fuel, providing green fertiliser to the Brazilian marketplace, and allowing export of green ammonia as an energy source. With up to 25 metres draft, the port will be able to welcome the largest and most modern ships in the world and, when operational, Porto Central will be one of the most innovative ports in the world and a major green energy hub.

AmmPower has also signed a letter of intent to develop another 4,000 tonnes per day green ammonia facility at the Port of Southern Louisiana (PoSL). PoSL is the largest tonnage port in the Western hemisphere and the second largest port of energy transfer in the United States. This facility will be one of the first of its kind, to help transition one of the world’s largest ports to a green energy source.

AmmPower will be an early maritime leader in the green shipping industry and a key leader in the movement of green hydrogen as an energy source.

Ammonia fertiliser market

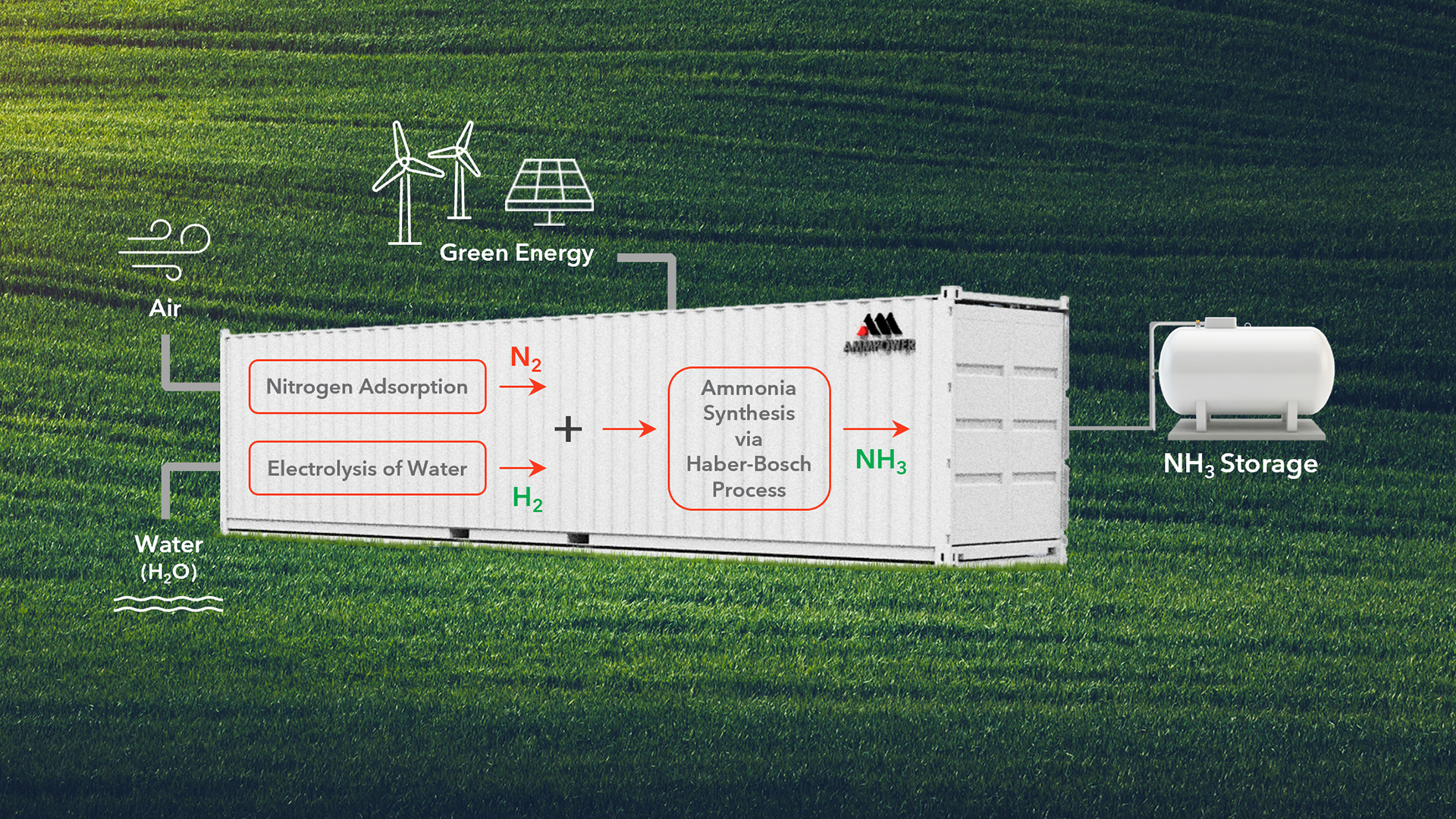

AmmPower is currently developing a modular, scaleable green ammonia production unit, named IAMMTM (Independent Ammonia Making Machine). As the acronym suggests, the IAMM is an independent system that will be capable of generating four tonnes of ammonia per day.

The IAMM system creates green ammonia for use as fertiliser in the agricultural industry from renewable energy and the electrolysis of water. This means there are no fossil fuels used to generate the hydrogen needed for ammonia synthesis and there are no carbon emissions produced.

One of the most important ways for energy independence is for countries to build their own renewable energy infrastructure. The AmmPower IAMM unit is designed to produce green hydrogen through electrolysis, isolate nitrogen from the air, and convert them into ammonia using renewable electricity, rendering it independent from both natural gas and oil prices.

Through developing, building and marketing smaller ammonia production units that are financially feasible for the customer, AmmPower will disrupt the anhydrous ammonia fertiliser market.

This strategy will allow the economical production of anhydrous ammonia without having to rely on availability and transportation issues encountered in the ammonia supply chain today.

The IAMM will allow farmers and fertiliser-makers to take control of their own ammonia supply for the first time.

References

1 www.eia.gov/naturalgas/weekly/archivenew_ngwu/2021/04_01

2 royalsociety.org/-/media/policy/projects/green-ammonia/green-ammonia-policy-briefing.pdf

3 www.aiche.org/resources/publications/cep/2016/september/introduction-ammonia-production

4 www.intelligentliving.co/ammonia-fuel-of-the-future

Please note, this article will also appear in the tenth edition of our quarterly publication.